Loading...

Loading...

Do you have a question about the Zetor MAJOR and is the answer not in the manual?

| Hydraulic System | Open center |

|---|---|

| Displacement | 4.156 l |

| Number of Cylinders | 4 |

| PTO Speed | 540/1000 rpm |

| Engine Type | Zetor |

| Engine | Zetor |

Key safety rules, operating precautions, and appropriate attire for safe tractor use.

Safe procedures for starting the engine, driving, and transporting persons.

Safety for leaving tractor, recovery, and fire prevention measures.

Precautions for chemicals, oils, waste, cab, and AC systems.

Safety for electrical installations and operation in aggressive environments.

Operator exposure to noise, vibration, and safety for front end loaders.

Specific safety requirements for operating Zetor tractors in woods.

Procedures for checking fuel system leaks and engine oil level.

Inspection of cooling system and hydrostatic steering.

Checks for trailer brakes, hitches, and after-work cooler cleaning.

Checks for tires, wheels, and a short functional test of key systems.

Guidance on entering/exiting the cab and operating doors.

Instructions for operating rear, side windows, and hinged lid.

Adjustments for driver's seat, steering wheel, and dashboard layout.

Operation of ignition, heating, AC, and dashboard indicators.

Operation of hydraulic controls, pedals, and differential lock.

Operation of reversing, gear shifting, and PTO levers.

Operation of front drive axle, PTO engagement, and battery disconnector.

Essential checks before starting and the engine starting procedure.

Steps for engine start failure and proper engine warm-up.

Safe driving away, engine performance limits, and speed selection.

Techniques for gear shifting and safe driving on slopes.

Using brakes, differential lock, and front drive axle.

Operation and safety for trailer brakes, and stopping procedures.

Final steps before leaving, and warnings for system failures.

Guidelines for the first 100 hours of tractor operation.

Use of front hook and adjustments for multistage suspension.

Operation of CBM hitch, drawbar, and modular suspension systems.

Maximum permitted static loads for trailer suspensions.

General safety and procedures for working with the PTO shaft.

Manual disengagement, engagement, and speed selection for PTO shaft.

Understanding independent and dependent PTO shaft revolutions.

Using freewheel for driving machines with high inertia masses.

Description of hydraulic equipment, panel, and control elements.

Using free, position, power, and mixed regulation modes.

Function and control of external hydraulic outlets and quick-couplers.

Safe engagement and disengagement of quick-couplers.

Categories and specifications for rear three-point linkage.

Adjustments and safety precautions for draw bars.

Connecting tools using lower and upper draw bars with CBM hooks.

Changing front wheel track and adjusting toe-in.

Adjustment of front axle fenders and rear wheel track.

Placement of ballast weights and valve for tire liquid filling.

Step-by-step procedures for filling and draining tires with liquid.

Preparation and safety for anti-freeze solutions used in tires.

General electrical connection guidelines and accumulator battery.

Maintenance procedures for the accumulator battery and alternator.

Location of fuse box, fuse placement, and lighting adjustments.

Daily, 100-hour, 500-hour, and beyond maintenance tasks.

Schedule for replacing fluids and filters, and fluid capacities.

Recommended Zetor service fluids and oil specifications.

Specifications for lubricants, cooling liquid, and fuel.

Identification of greasing points for drive axle and linkage.

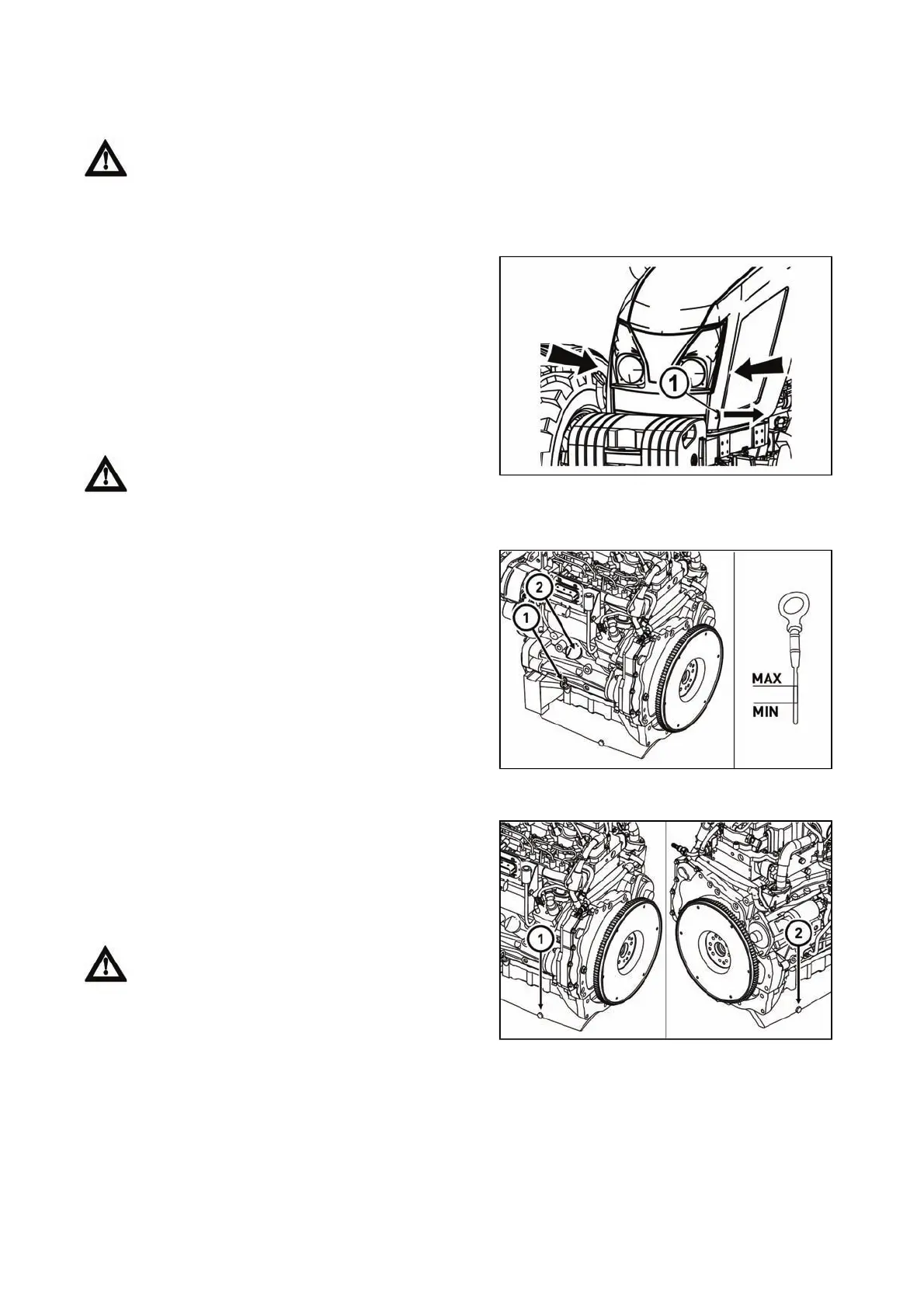

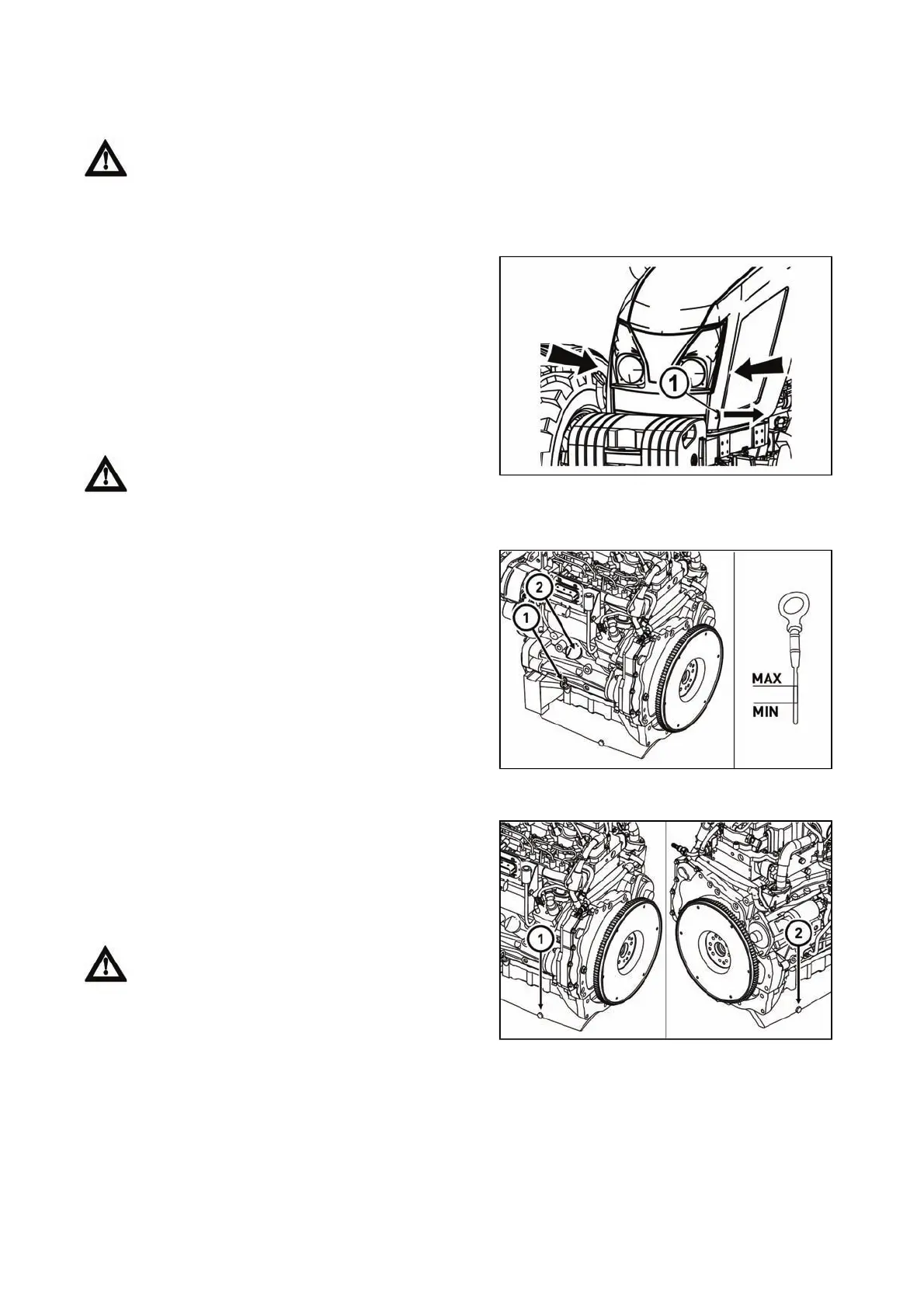

Procedures for opening the bonnet and checking engine oil.

Steps for draining engine oil and replacing the oil filter.

Procedures for cleaning and replacing fuel filter cartridges.

Bleeding the fuel system and maintaining the air filter.

Checking steering oil level and replacing filter element.

Replacing steering hoses and bleeding the heating system.

Procedures for coolant replacement and checking axle oils.

Replacing hydraulic pump filter and changing gear system oil.

Oil procedures for front drive axle and wheel reducers.

Maintenance of air-condition filtration elements and condenser.

Inspecting tires, inflating them, and procedures for tractor storage.

Adjusting tension for accessory drive belts and V-belts.

Adjusting the PTO shaft clutch control lever and clutch pedal free run.

Key tractor dimensions, weight, and engine technical data.

Axle load capacities, combined weight limits, and tire data.

Hydraulic system specifications and tractor speed charts.

PTO shaft performance and tractor turning circle dimensions.