Fuel system venting

The fuel system gets bled using an electric booster fuel pump.

Do not start up the engine while bleeding so that no error messages be generated.

1. Turn the key in the switch box from the position 0 to the position I

2. The booster fuel pump will be running for about 20 seconds which makes the air blow off of the fuel

system and its pressurization

3. Wait until the booster fuel pump switches off by itself

4. Turn the key in the switch box from the position I to the position 0

5. Repeat this procedure two more times at least

6. After you start up the engine make a tightness check of the fuel system

Air Filter Maintenance

Recovery of the mainair cleaner element

Replacing the safety element of the air cleaner

The air filter is located in the front part of the tractor and is

accessible after the front bonnet has been lifted off.

Air filter maintenance shall be carried out once air filter

pollution gets signalled.

Carry out the air filter maintenance according to the

following procedure:

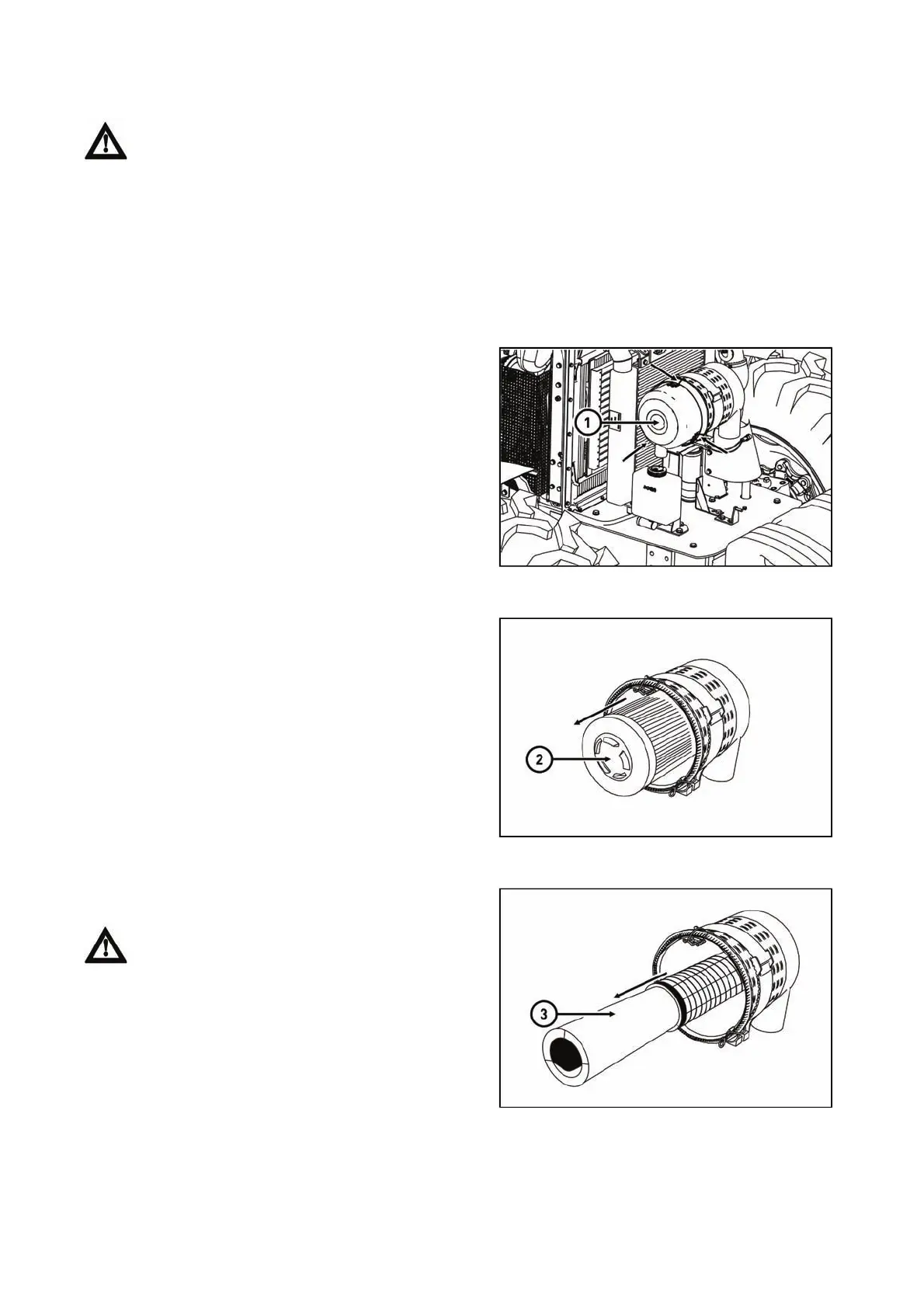

1. Lift off the front bonnet

2. Loosen the clips of the air filter cover (marked with

arrows)

3. Take off the filter cover (1)

NM14D014

Remove the main element of the dry cleaner (2) by

pulling.

If the main element is not damaged (there must not be any

dust on the inner side of the element), recover it by

blowing pressurized air from the inner side of the element.

This way you can recover the main element 3 times at the

most. The element must be replaced once a year.

NM14D015

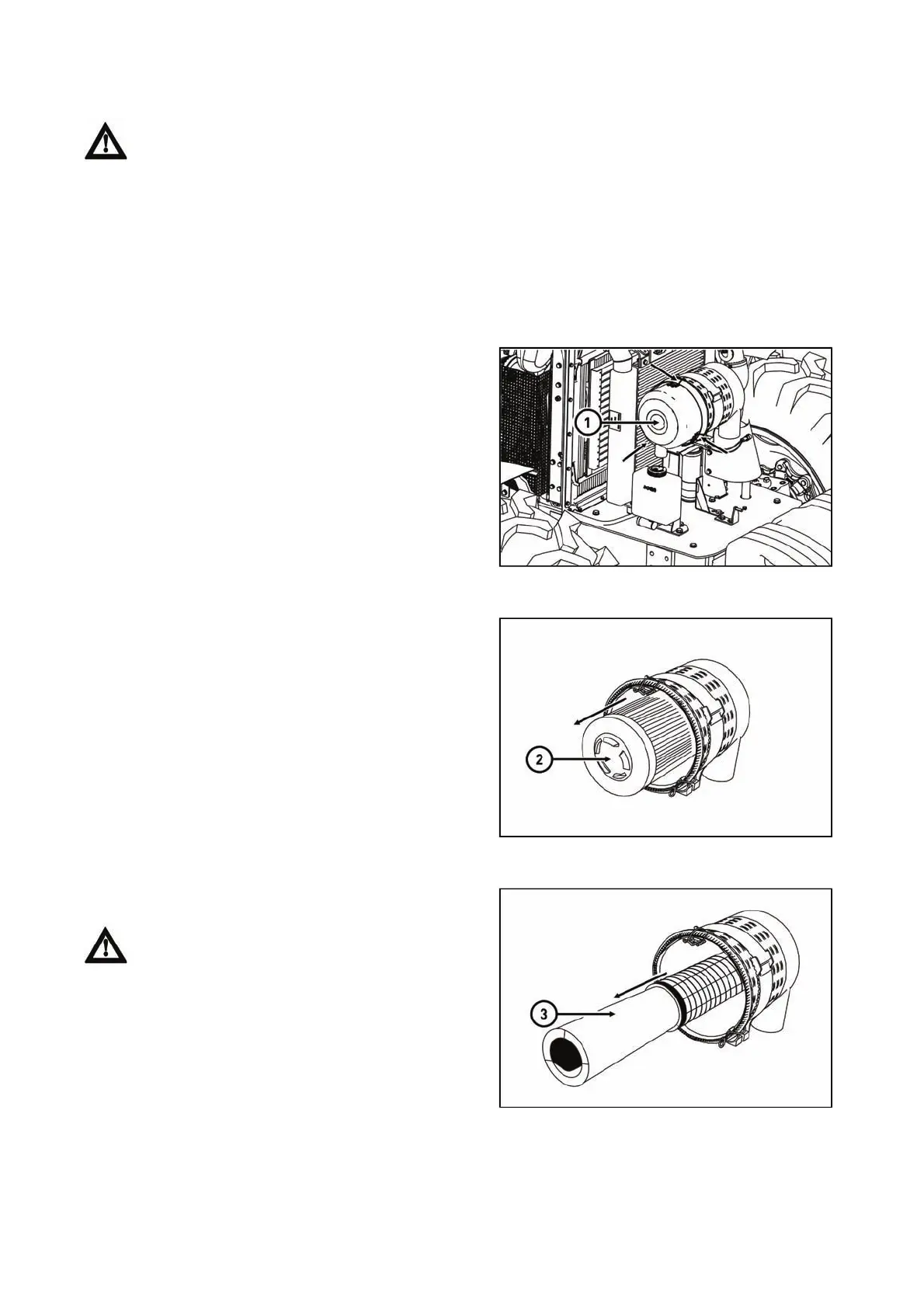

Remove the safety element of the dry cleaner (3) by

pulling.

The safety element cannot be recovered. It

must always be replaced in these cases.

- If the main element is damaged.

- After covering 2000 hours of work

- At least once every two years.

NM14D016

Loading...

Loading...