264 Additional parameter data

Fieldbus equivalents

Serial communication data between the fieldbus adapter and the drive is transferred

in integer format. Thus, the drive actual and reference signal values must be scaled

to 16/32-bit integer values. The fieldbus equivalent defines the scaling between the

signal value and the integer used in serial communication.

All the read and sent values are limited to 16/32 bits.

Example: If 24.03 Maximum torq ref is set from an external control system, an integer

value of 10 corresponds to 1%.

Pointer parameter format in fieldbus communication

Value and bit pointer parameters are transferred between the fieldbus and drive as

32-bit integer values.

32-bit integer value pointers

When a value pointer parameter is connected to the value of another parameter, the

format is as follows:

For example, the value that should be written into parameter 33.02 Superv1 act to

change its value to 01.07 Dc-voltage is

0100 0000 0000 0000 0000 0001 0000 0111 = 1073742087 (32-bit integer).

Type Data type. See enum, INT32, Bit pointer, Val pointer, Pb, REAL, REAL24,

UINT32.

UINT32 32-bit unsigned integer value.

Val pointer Value pointer. Points to the value of another parameter.

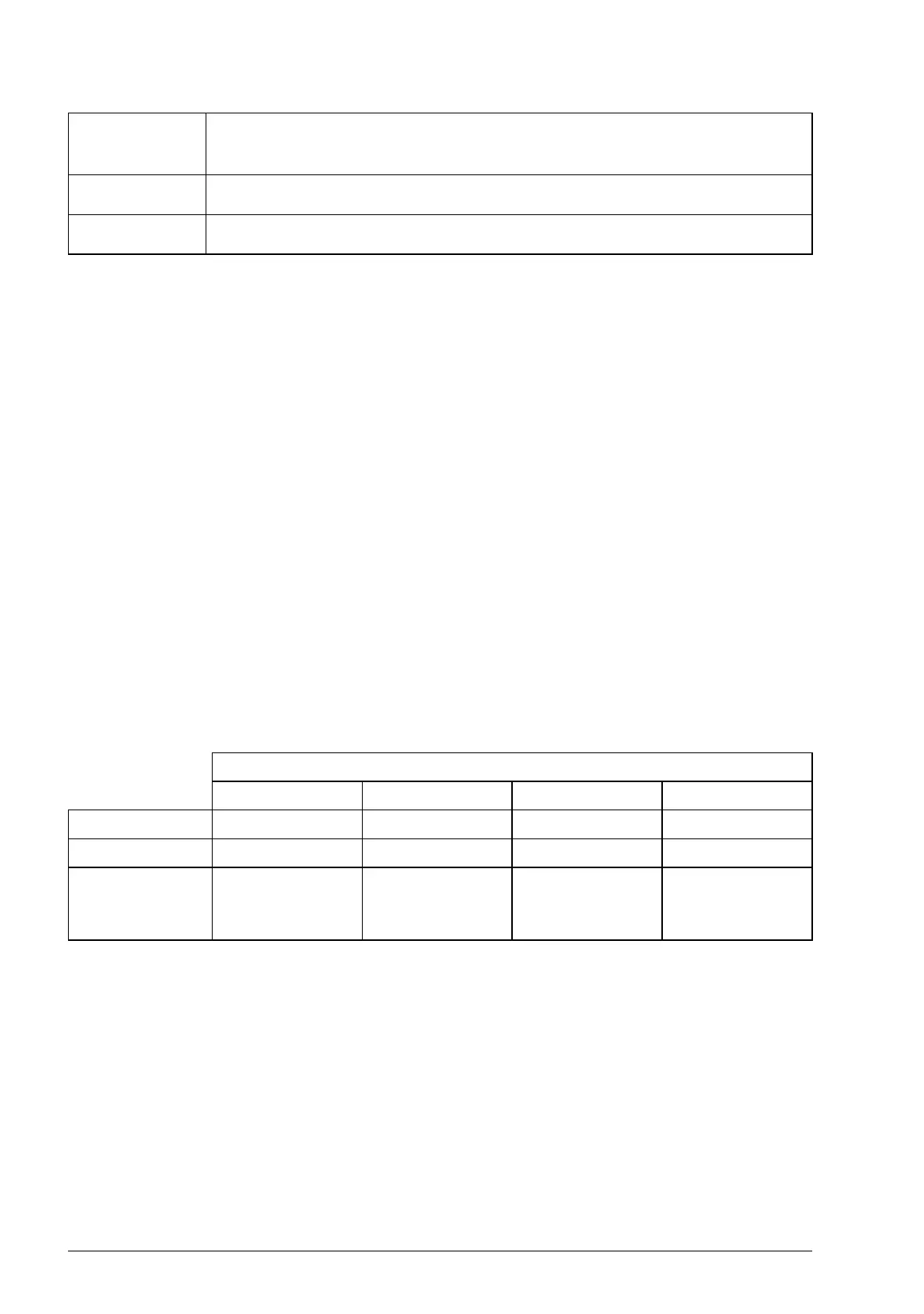

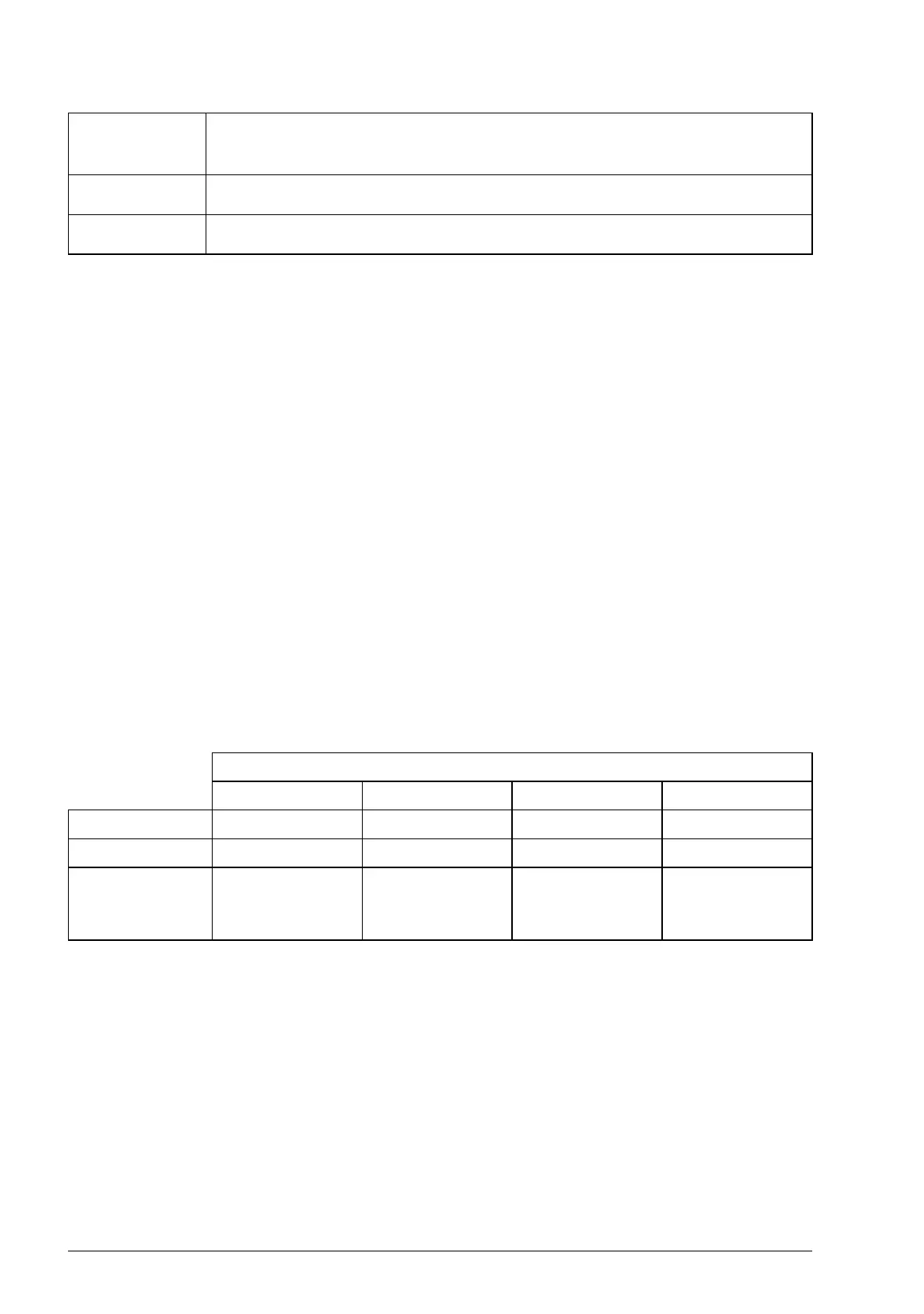

Bit

30…31 16…29 8…15 0…7

Name Source type Not in use Group Index

Value 1 - 1…255 1…255

Description Value pointer is

connected to

parameter

- Group of source

parameter

Index of source

parameter

Loading...

Loading...