44 TTF300 FIELD-MOUNT TEMPERATURE TRANSMITTER | OI/TTF300-EN REV. I

10 Operation

Safety instructions

If there is a chance that safe operation is no longer possible,

take the device out of operation and secure it against

unintended startup.

Hardware settings

Devices with HART® from HW-Rev.: 02.00 (corresponds

to Software from SW-Rev.: 03.00 and higher)

HART devices from HW-Rev.: 02.00 do not have DIP switches.The

desired HART profile (HART 7 or HART 5) the write protection are

set via the operating buttons of the LCD display (optional), tools

or HART commands.

Note

Factory setting, unless explicitly ordered otherwise:

• HART 7

• Write protection OFF

Devices with PROFIBUS PA®, FOUNDATION Fieldbus®,

and HART® to HW-Rev.: 01.07

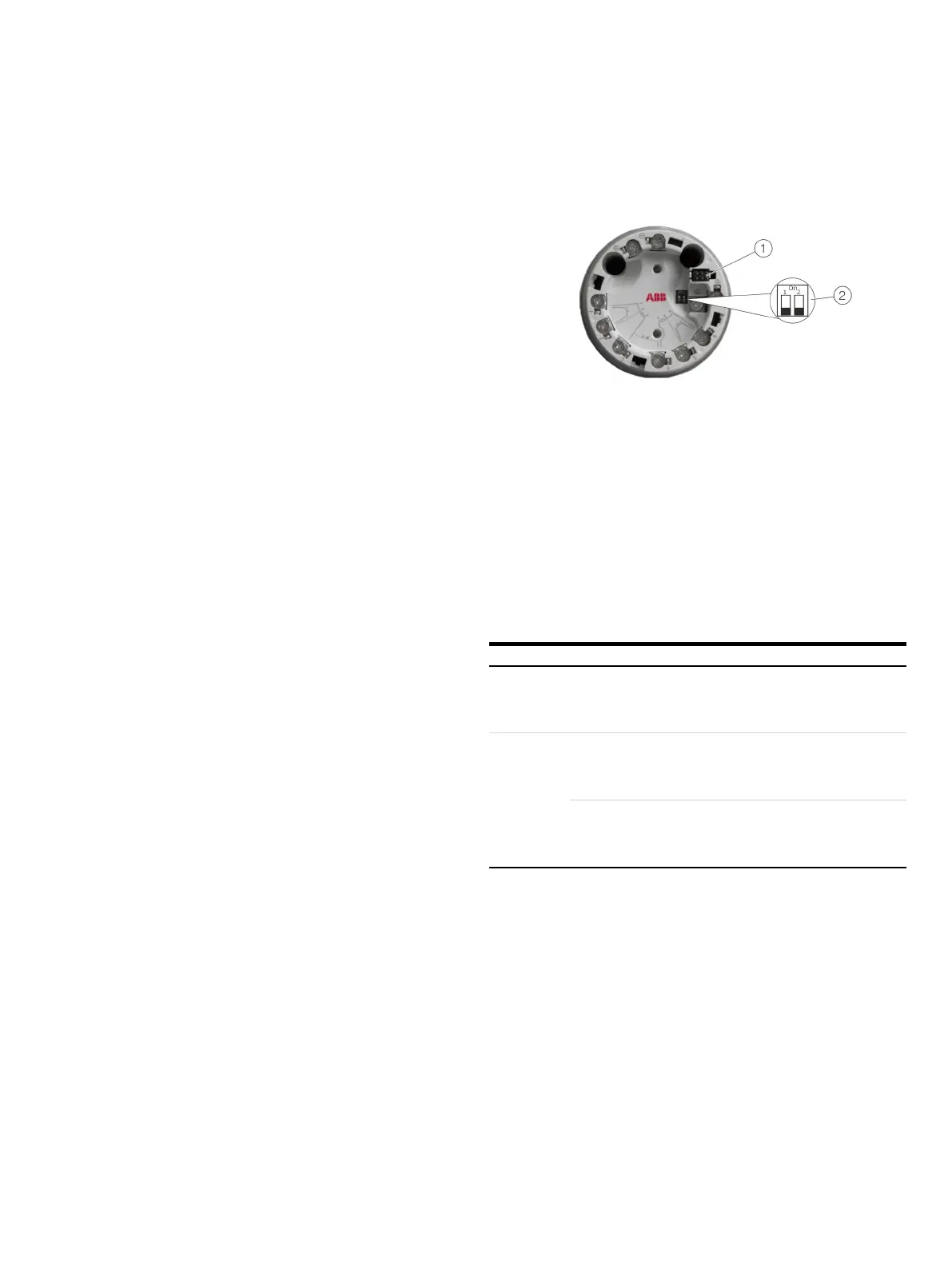

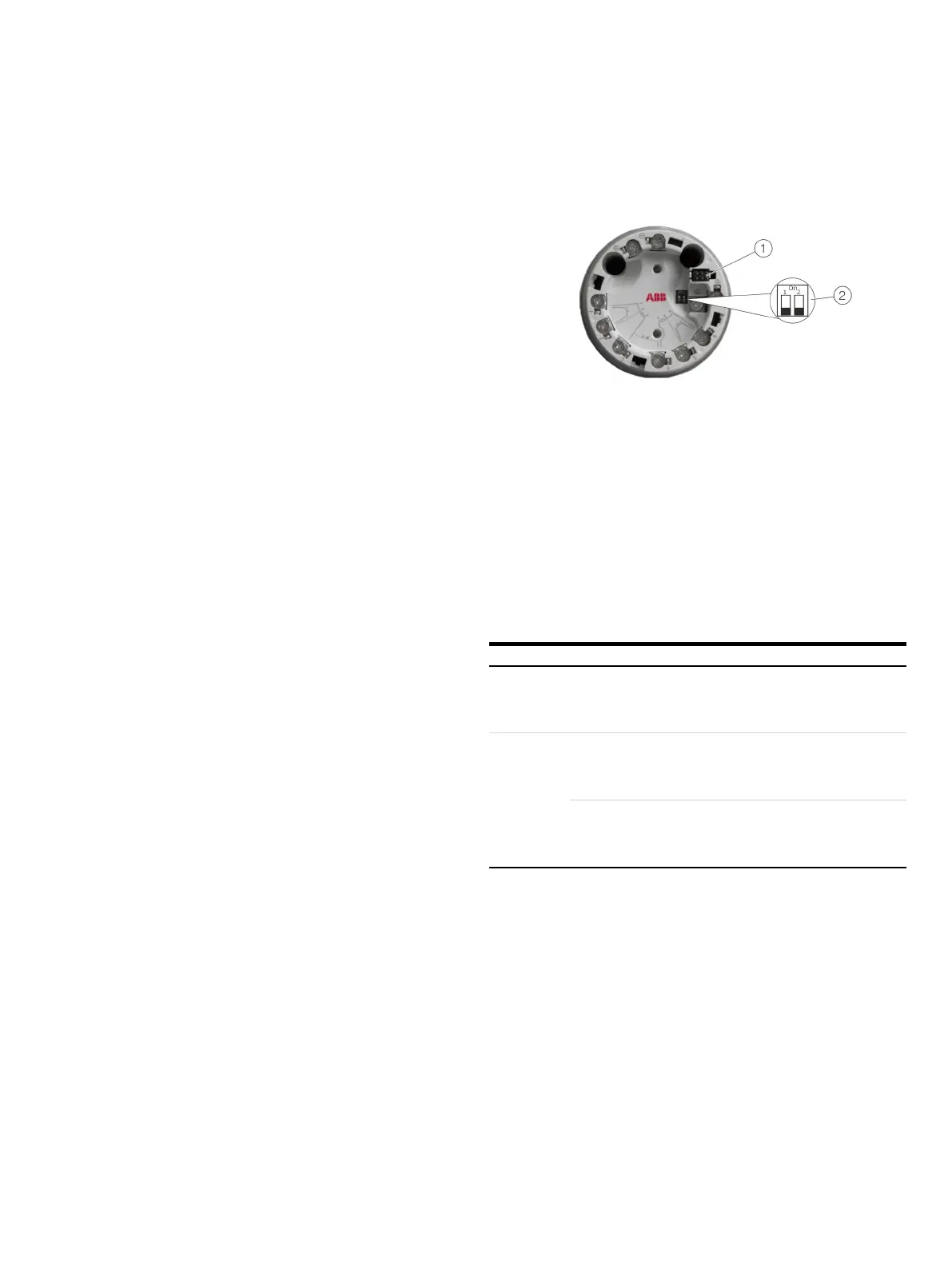

LCD indicator interface

DIP switch

Figure 34: DIP switch on the transmitter (not for HART devices from HW-Rev.: 02.00)

The transmitter has two DIP switches that can be accessed via a

hinged cover.

• Switch 1 activates the hardware write protection.

• Switch 2 supports the FOUNDATION Fieldbus

requirement for a hardware enable for simulation in

accordance with ITK.

For transmitters that support HART 7, switch 2 allows the

desired HART version to be set (HART 5 or HART 7).

: Local write protection deactivated

: Local write protection activated

Enabling the simulation (only with FOUNDATION Fieldbus)

: Simulation blocked

: Simulation enabled

Selecting the HART version (only with HART protocol)

: HART 5

: HART 7

Note (not for HART devices from HW-Rev.: 02.00)

• Factory settings: Both switches ‘OFF’. Local write protection

deactivated and HART 5, unless explicitly ordered HART 7

(HART version) or simulation locked (FOUNDATION Fieldbus).

• With PROFIBUS PA devices, Switch 2 must always be in the

‘OFF’ position.

Loading...

Loading...