Rockwell Automation Publication 2094-UM001J-EN-P - March 2017 97

Connect the Kinetix 6000 Drive System Chapter 5

Power Wiring Requirements

Wire must be copper with 75 °C (167 °F) minimum rating. Phasing of main

AC power is arbitrary and earth ground connection is required for safe and

proper operation.

For IPIM module power wiring requirements, refer to the Kinetix 6000M

Integrated Drive-Motor System User Manual, publication 2094-UM003

.

Refer to Power Wiring Examples on page 189

for interconnect diagrams.

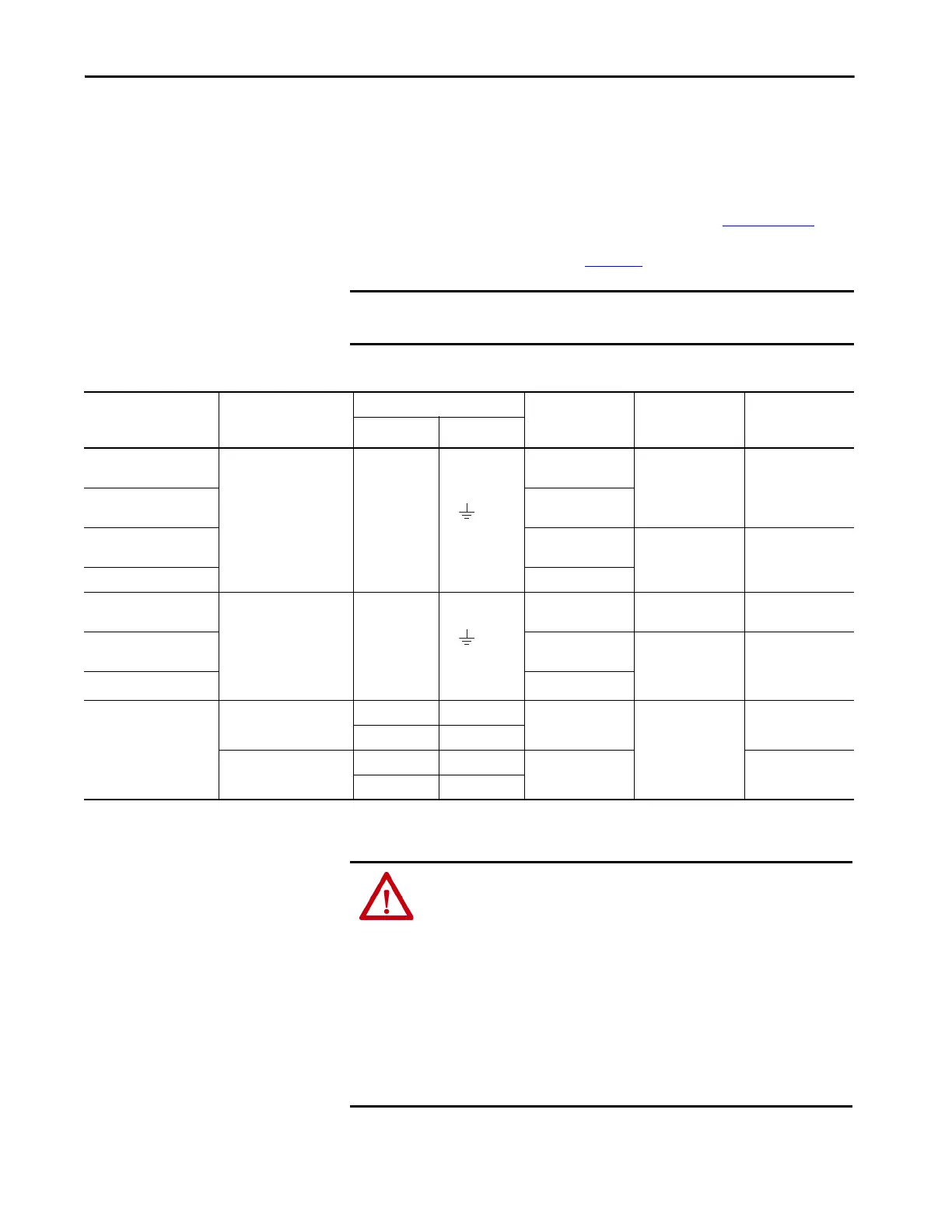

Table 60 - IAM Power Wiring Requirements

IMPORTANT The National Electrical Code and local electrical codes take precedence

over the values and methods provided.

Kinetix 6000 Drive

Cat. No.

Description

Connects to Terminals Recommended Wire

Size

mm

2

(AWG)

Strip Length

mm (in.)

Torque Value

N•m (lb•in)

Pin Signal

2094-AC05-Mxx-x

DC bus

(1)

and

VAC input power

IPD-1

IPD-2

IPD-3

IPD-4

IPD-5

IPD-6

6…2.5

(10…14)

10

(0.38)

0.5…0.6

(4.4…5.3)

2094-AC09-M02-x

6…4

(10…12)

2094-AC16-M03-x

30…10

(3…8)

16

(0.63)

2.4…3.0

(21.6…26.5)

2094-AC32-M05-x 30 (3)

2094-BC01-Mxx-x

2094-BC02-M02-x

DC bus

(1)

and

VAC input power

IPD-1

IPD-2

IPD-3

IPD-4

IPD-5

IPD-6

10…2.5

(8…14)

10

(0.38)

1.2…1.5

(10.6…13.2)

2094-BC04-M03-x

10…6

(8…10)

16

(0.63)

2.4…3.0

(21.6…26.5)

2094-BC07-M05-x 30 (3)

2094-xCxx-Mxx-x

Control input power

CPD-1 CTRL 2

4…2.5

(12…14)

10

(0.38)

0.5…0.6

(4.4…5.3)

CPD-2 CTRL 1

Contactor Enable

CED-1 CONT EN-

4…2.5

(12…14)

(2)

0.5…0.6

(4.4…5.3)

CED-2 CONT EN+

(1) Keep DC common-bus connections (leader IAM to follower IAM module) as short as possible.

(2) The actual gauge of the contactor enable wiring depends on the system configuration. Consult your machine builder, the NEC, and applicable local codes.

ATTENTION: To avoid personal injury and/or equipment damage, make sure

installation complies with specifications regarding wire types, conductor

sizes, branch circuit protection, and disconnect devices. The National

Electrical Code (NEC) and local codes outline provisions for safely installing

electrical equipment.

ATTENTION: To avoid personal injury and/or equipment damage, make sure

motor power connectors are used for connection purposes only. Do not use

them to turn the unit on and off.

ATTENTION: To avoid personal injury and/or equipment damage, make sure

shielded power cables are grounded to prevent potentially high voltages on

the shield.

Loading...

Loading...