Publication 1762-RM001C-EN-P

19-2 Process Control Instruction

The PID Equation

The PID instruction uses the following algorithm:

Standard equation with dependent gains:

Standard Gains constants are:

The derivative term (rate) provides smoothing by means of a low-pass

filter. The cut-off frequency of the filter is 16 times greater than the corner

frequency of the derivative term.

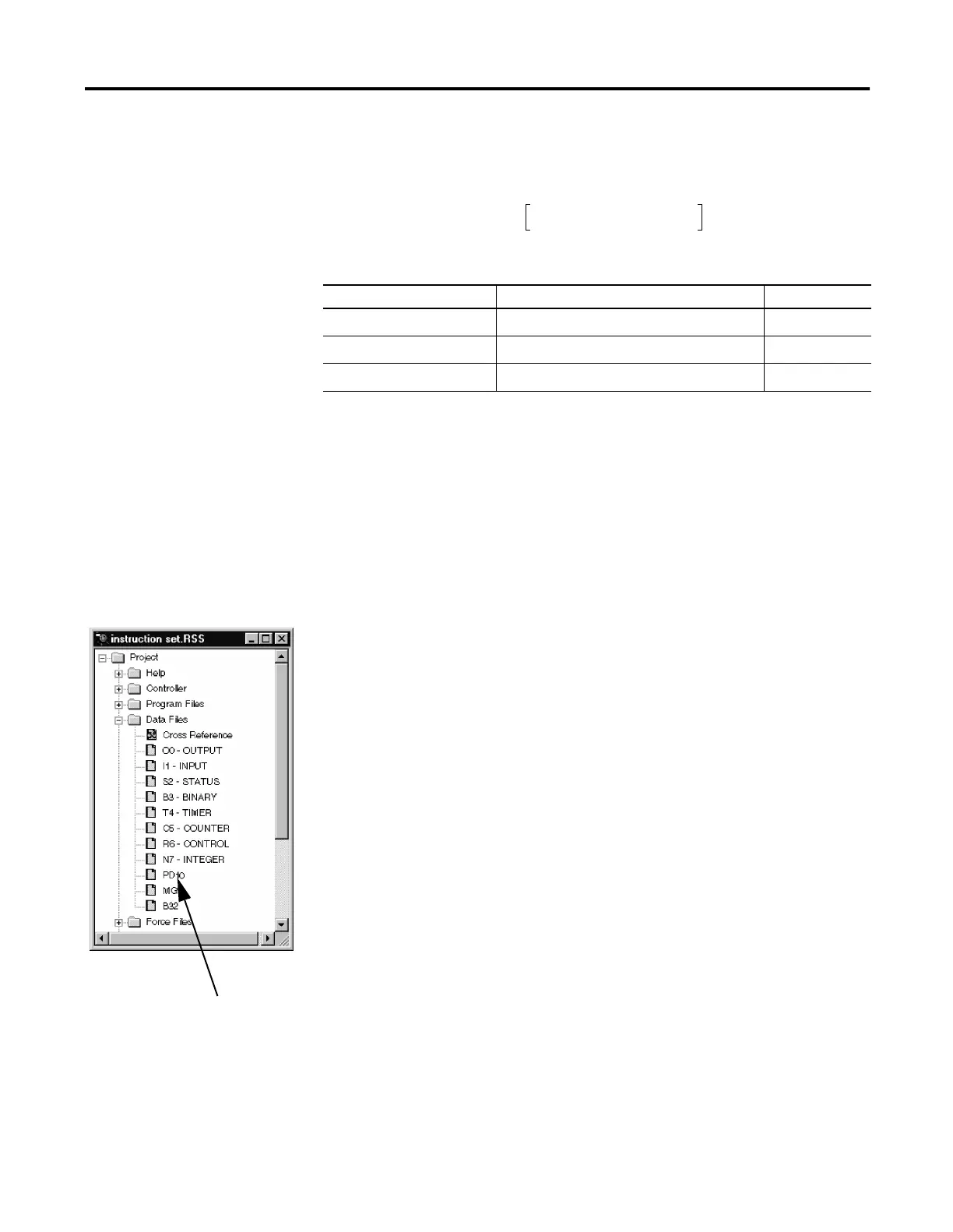

PD Data File

The PID instruction implemented by the MicroLogix 1200 and 1500

controllers is virtually identical in function to the PID implementation

used by the Allen-Bradley SLC 5/03 and higher processors. Minor

differences primarily involve enhancements to terminology. The major

difference is that the PID instruction now has its own data file. In the SLC

family of processors, the PID instruction operated as a block of registers

within an integer file. The Micrologix 1200 and 1500 PID instruction

utilizes a PD data file.

You can create a PD data file by creating a new data file and classifying it

as a PD file type. RSLogix automatically creates a new PD file or a PD

sub-element whenever a PID instruction is programmed on a rung. The

PD file then appears in the list of Data Files as shown in the illustration.

Each PD data file has a maximum of 255 elements and each PID

instruction requires a unique PD element. Each PD element is composed

of 20 sub-elements, which include bit, integer and long integer data. All of

the examples in this chapter use PD file 10 sub-element 0.

Term Range (Low to High) Reference

Controller Gain K

C

0.01 to 327.67 (dimensionless)

(1)

(1) Applies to MicroLogix 1200 and 1500 PID range when Reset and Gain Range (RG) bit is set to 1. For more information

on reset and gain, see PLC 5 Gain Range (RG) on pa ge19-13.

Proportional

Reset Term 1/T

I

327.67 to 0.01 (minutes per repeat)

(1)

Integral

Rate Term T

D

0.01 to 327.67 (minutes)

(1)

Derivative

Output K

C

E()

1

T

I

-----

E()td

∫

T

D

dPV()

dt

--------- ------

⋅++ bias+=

PD file created by

RSLogix 500.

Loading...

Loading...