Design a sequential function chart

20 Rockwell Automation Publication 1756-PM006I-EN-P - February 2018

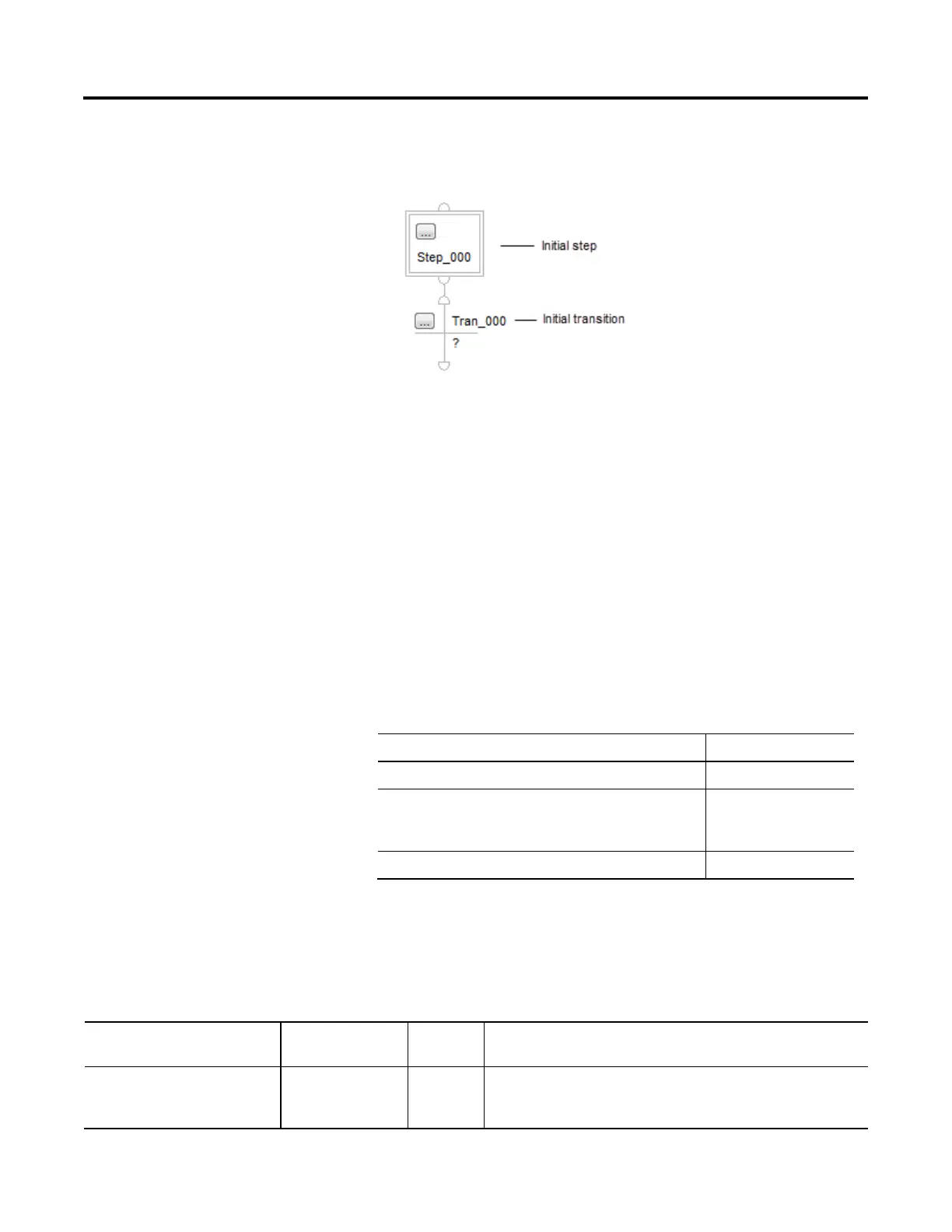

• When you first open an SFC routine, it contains an initial step and

transition. Use this step to initialize your process.

The controller executes the initial step in these situations.

• After a project download when the controller goes into Run mode.

• When the controller transitions to Run mode and on power-up (if the

SFC is configured for that).

• When the routine containing the chart is modified online and a reset is

required, and the controller transitions to or from Test mode.

• To identify a step, look for a physical change in your system, such as new

part that is in position, a temperature that is reached, a preset time that is

reached, or a recipe selection that occurs. The step is the actions that take

place before that change.

• Stop refining the steps when they are in meaningful increments. This is an

example.

This organization of steps Is

produce_solution Probably too large

set_mode, close_outlet, set_temperature, open_inlet_a, close_inlet_a,

set_timer, reset_temperature, open_outlet, reset_mode

Probably too small

preset_tank, add_ingredient_a, cook, drain Probably about right

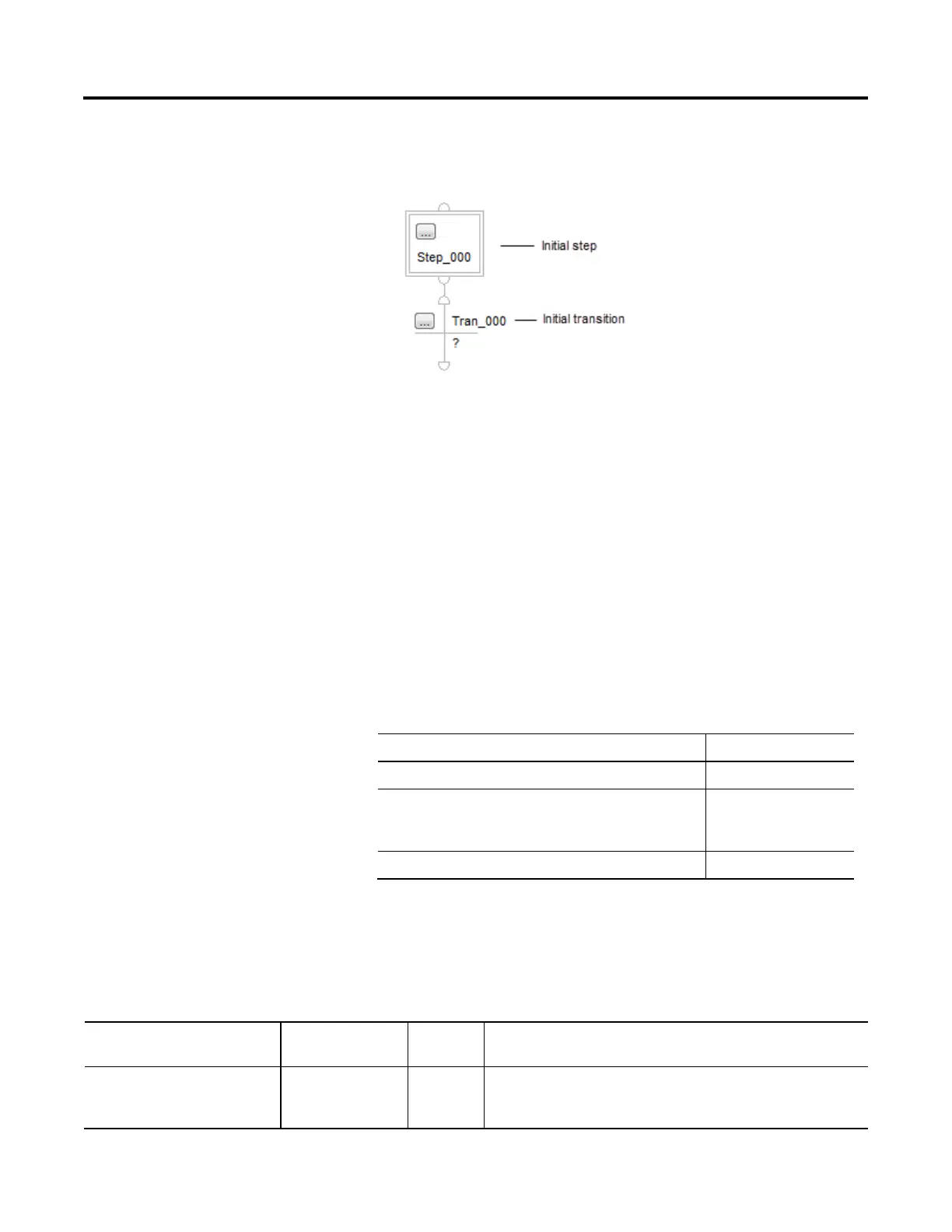

Each step uses a tag to provide information about the step. Access this

information with either the Step Properties dialog box or the Monitor Tags tab

of the Tags window.

If you want to

Then select or set this

member

Data type Details

Determine how long a step has been active

(milliseconds)

T DINT

When a step becomes active, the Timer (T) value resets and then starts to count up in

milliseconds. The Timer continues to count up until the step goes inactive, regardless of

the Preset (PRE) value.

Loading...

Loading...