34/72 Installation

BoschRexrothAG, axial piston variable pump A4VSO, RE 92050-01-X-B1/2019.08.23

CAUTION

Risk ofdamage with inside-reservoir installation!

To prevent damages to the axial piston unit, all plastic parts (e.g. protective

caps,covers) must be removed prior to installation in the reservoir.

▶ Remove all plastic parts before installing the axial piston unit in the reservoir.

Make sure that noparts ofthem remain inthe reservoir.

▶ Axial piston units with electrical component must not be installed below the

hydraulic fluid level.

4

3

SB

h

t min

h

min

R(L)

T

U

K

1,2

S

h

t min

h

min

R(L)

T

U

S

K

1,2

SB

1)

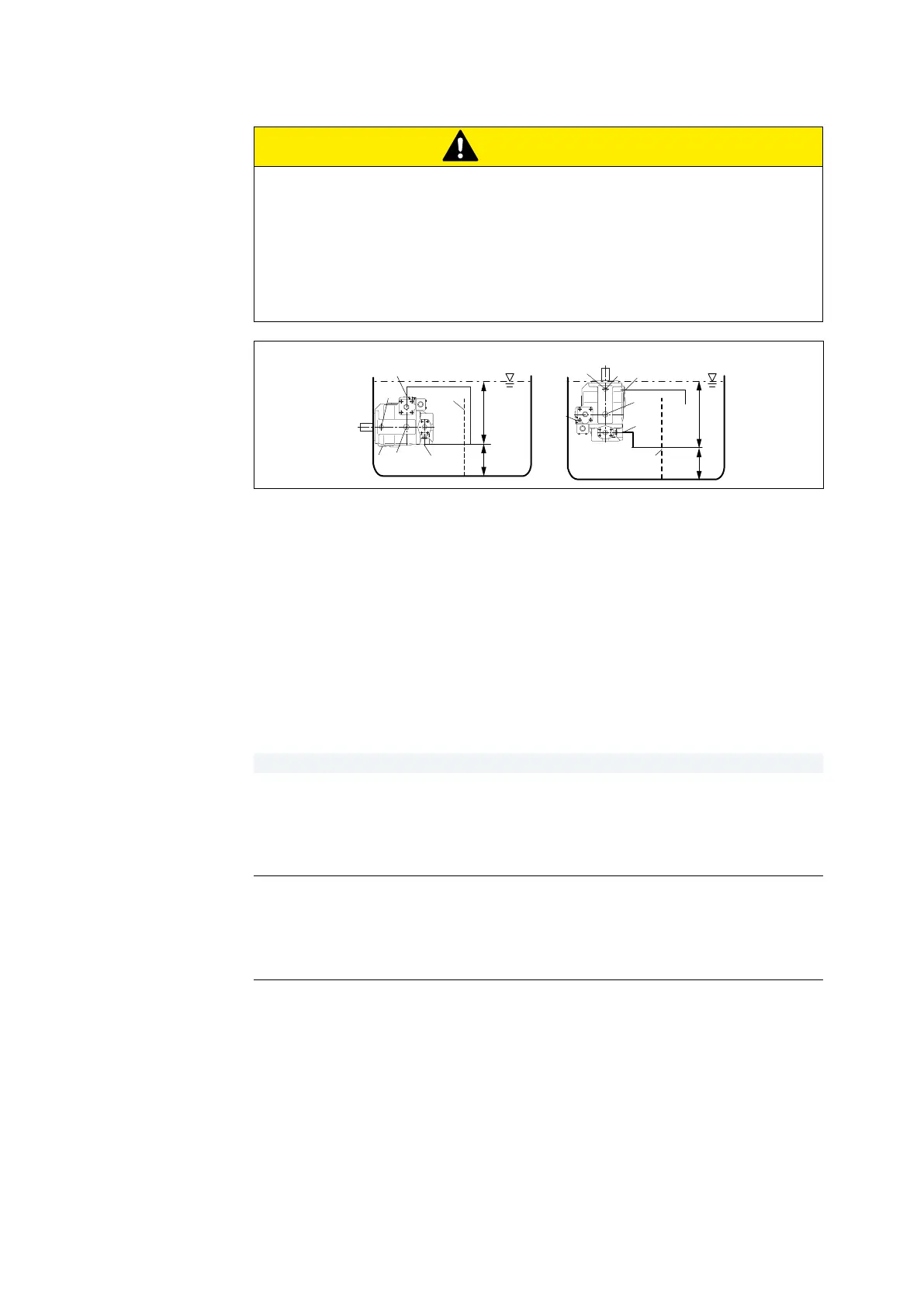

Fig. 7: Inside-reservoir installation with horizontal installation position3 and vertical installation

position 4

1)

Install bearing flushing, please refer to data sheet (Part II) for minimum flushing flow

R(L) Fluid filling and air bleeding

(drainport)

h

min

Minimum required distance

toreservoir bottom (100mm)

T Fluid drain h

t min

Minimum required immersion depth

(200mm)

S Suction port SB Baffle (baffle plate)

U Flushing port

Table 13: Inside-reservoir installation

Installation position Air bleed Filling

3 (drive shaft horizontal) via the highest open

portR(L)

With piping:

The axial piston unit must be filled before

the piping is attached.

Without piping:

Automatically via all open ports, by

position below hydraulic fluid level

4 (drive shaft

verticallyup)

Via the highest open

portT and bearing

flushing U

With piping:

The axial piston unit must be filled before

the piping is attached.

Without piping:

Automatically via all open ports, by

position below hydraulic fluid level

7.3.3 Above-reservoir installation

Above-reservoir installation means that theaxial piston unit isinstalled above

theminimum fluid level ofthereservoir.

Loading...

Loading...