56/72 Maintenance and repair

BoschRexrothAG, axial piston variable pump A4VSO, RE 92050-01-X-B1/2019.08.23

10.2 Inspection

In order to keep the axial piston unit running reliably for a long time, BoschRexroth

recommends testing the hydraulic system and axial piston unit on a regular basis,

and documenting and archiving the following operating conditions:

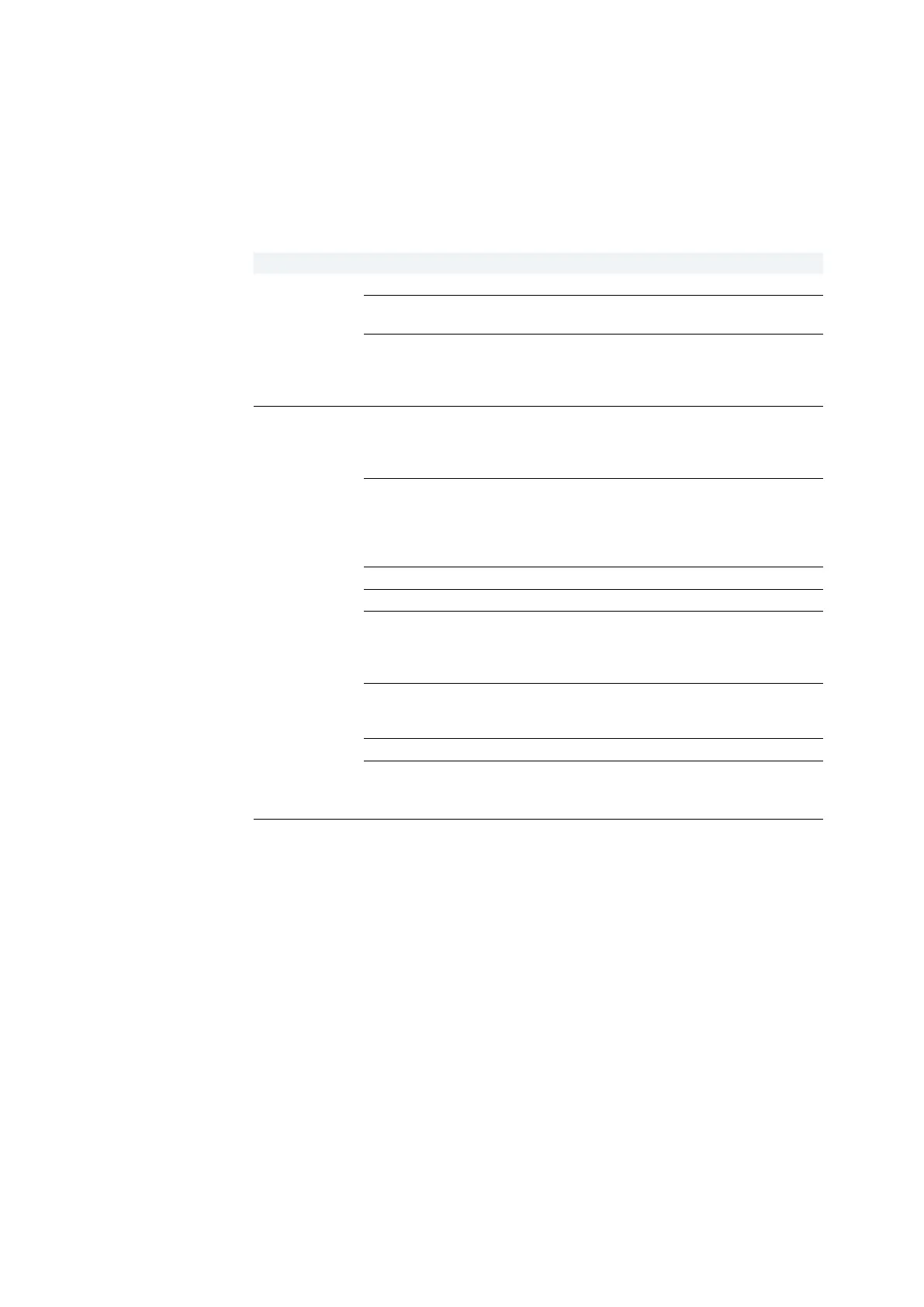

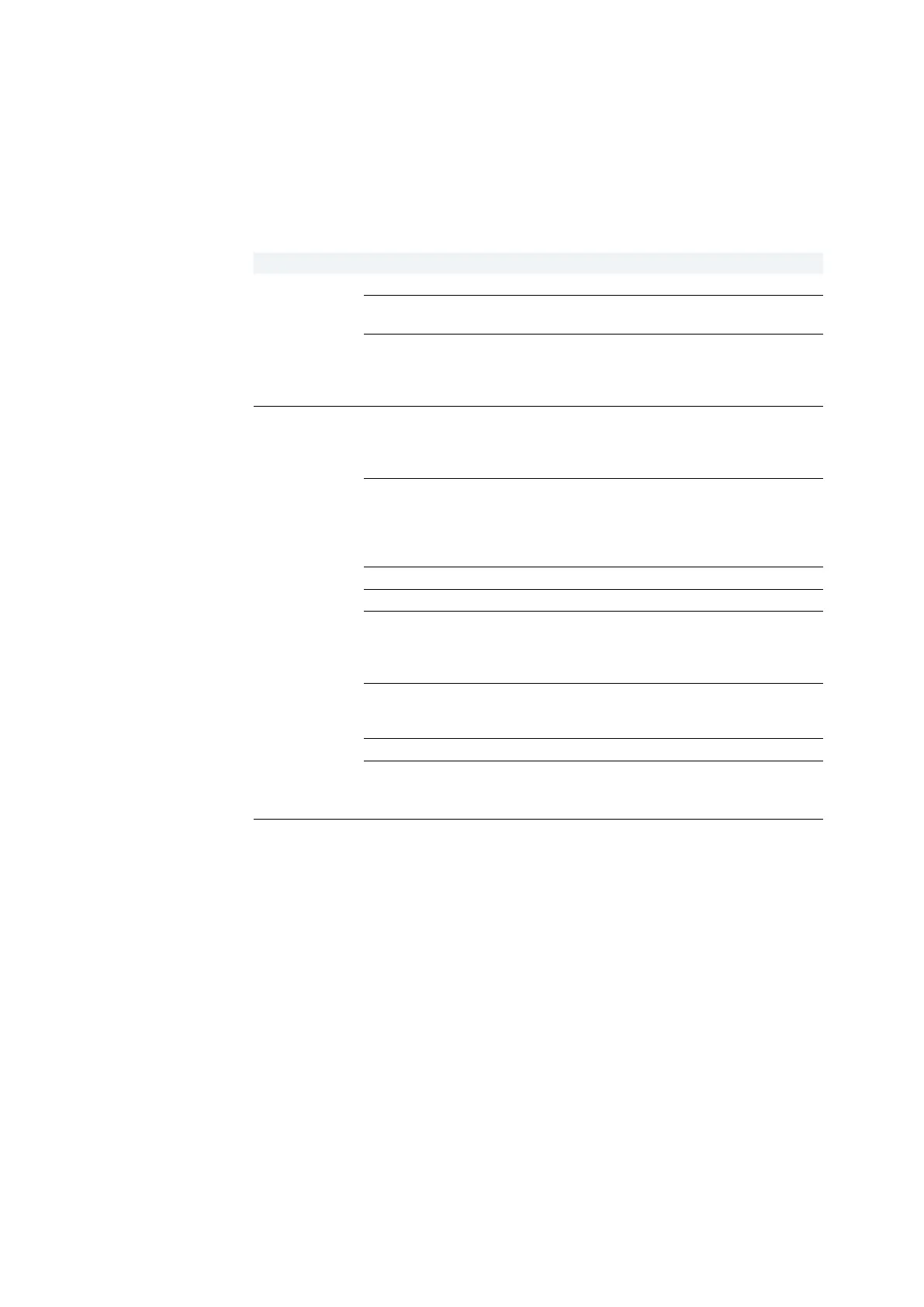

Table 17: Inspection schedule

Tasks tobe performed Interval

Hydraulic system Check hydraulic fluid level inthe reservoir. Daily

Check the operating temperature at a comparable load

condition at drain port and in the reservoir.

Weekly

Conduct hydraulic fluid analysis: Viscosity, aging and

contamination

Yearly orevery

2000operating

hours (whichever

occurs first)

Axial piston unit Check that the leakage temperature of the temperature

or inlet of the axial piston unit are within the specified

limits.Exceeding these limits means explosion protection

is no longer guaranteed.

Daily

Check axial piston unit for leakage.

Early detection ofhydraulic fluid loss can help tofind

fault

s onthe machine/system and rectify them. This

iswhy BoschRexroth recommends always keeping

theaxial piston unit and system clean

Daily

Check axial piston unit for unusual noise development. Daily

Visual inspection for external integrity, case damage. Daily

Visual inspection of paint for damage. Initiate repairs

as necessary in accordance with DINENISO80079-36

section 6.7. Otherwise, explosion protection is no

longer guaranteed.

Monthly

Check mounting elements for tight seating.

Check all fasteners only when the hydraulic system is

sw

itched off, depressurized and cooled down.

Monthly

Check ground connection lines for tight seating. Monthly

Remove dust deposits from between the shaft and the

sealing flange

Depending on

ambient conditions

Loading...

Loading...