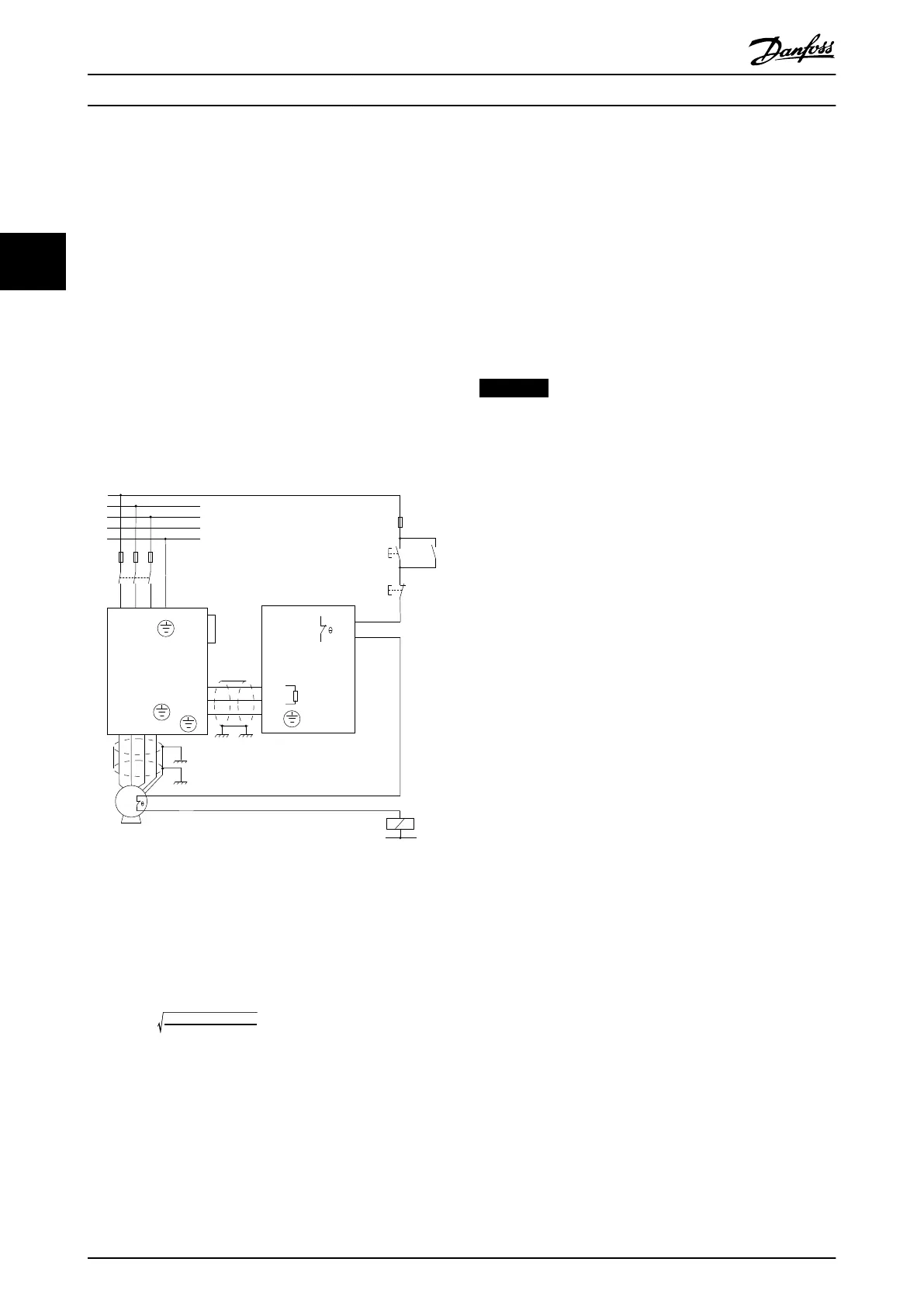

The temperature switch disabling the mains supply to

VLT by a contactor

Example 2

1. Connect the brake resistor built-in thermal switch

as controlling an input contactor. In this example,

the thermal switch within the brake resistor is

connected in series with the thermal switch

within the motor.

2. Connect start and stop push buttons in series

with the thermal switches.

3. Connect to a contactor in the mains supply in

front of the frequency converter.

Thermal overheating in brake resistor or motor disables

the mains supply to the frequency converter.

Example 2

91 92 93 95

96 97 98 99

M

3~

12

27

L1 L2 L3 PE

VLT

MCE 101

Brake resistor

T1

T2

RB1

RB2

99

PE

81

R -

82R+

PE

L1

L2

L3

N

PE

F1

S1 K1

F2

S2

K1

K1

U V W PE

130BD554.11

Illustration 3.19 Temperature Switch in both Motor and Brake

Resistor disabling Mains Supply by an Input Contactor

Thermo relay disabling the brake resistor

Example 3

Calculate the brake current (I

thermo relay

) setting of the

temperature switch as follows:

I

thermo relay

=

P

brake resistor max

R

br

R

br

is the current brake resistor value calculated in

chapter 4.1.2 Calculation of Brake Resistor Resistance.

Look up the brake current setting of the thermo relay for

Danfoss brake resistors in chapter 8 Selection Guide.

3.3.2

Brake Resistor and Brake IGBT

Brake resistor power monitor

In addition, the brake power monitor function makes it

possible to read out the momentary power and the mean

power for a selected time period. The brake can also

monitor the power energising and make sure it does not

exceed a limit selected in parameter 2-12 Brake Power Limit

(kW). In 2-13 Brake Power Monitoring, select the function to

carry out when the power transmitted to the brake resistor

exceeds the limit set in parameter 2-12 Brake Power Limit

(kW).

NOTICE

Monitoring the brake power does not fulfil a safety

function. The brake resistor circuit is not ground leakage

protected.

The brake is protected against short-circuiting of the brake

resistor, and the brake transistor is monitored to ensure

that short-circuiting of the transistor is detected. Use a

relay or digital output to protect the brake resistor against

overloading in the event of a fault in the frequency

converter, see chapter 3.3.1 Overtemperature Protection.

Overvoltage control (OVC) can be selected as an alternative

brake function in parameter 2-17 Over-voltage Control. If the

DC-link voltage increases, this function is active for all

units. The function ensures that a trip can be avoided. This

is done by increasing the output frequency to limit the

voltage from the DC link. It is a useful function, e.g. if the

ramp-down time is too short since tripping of the

frequency converter is avoided. In this situation the ramp-

down time is extended.

Installation Design Guide

14 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

33

Loading...

Loading...