Chapter 12 Description of Parameter SettingsC2000

12.1-07-2

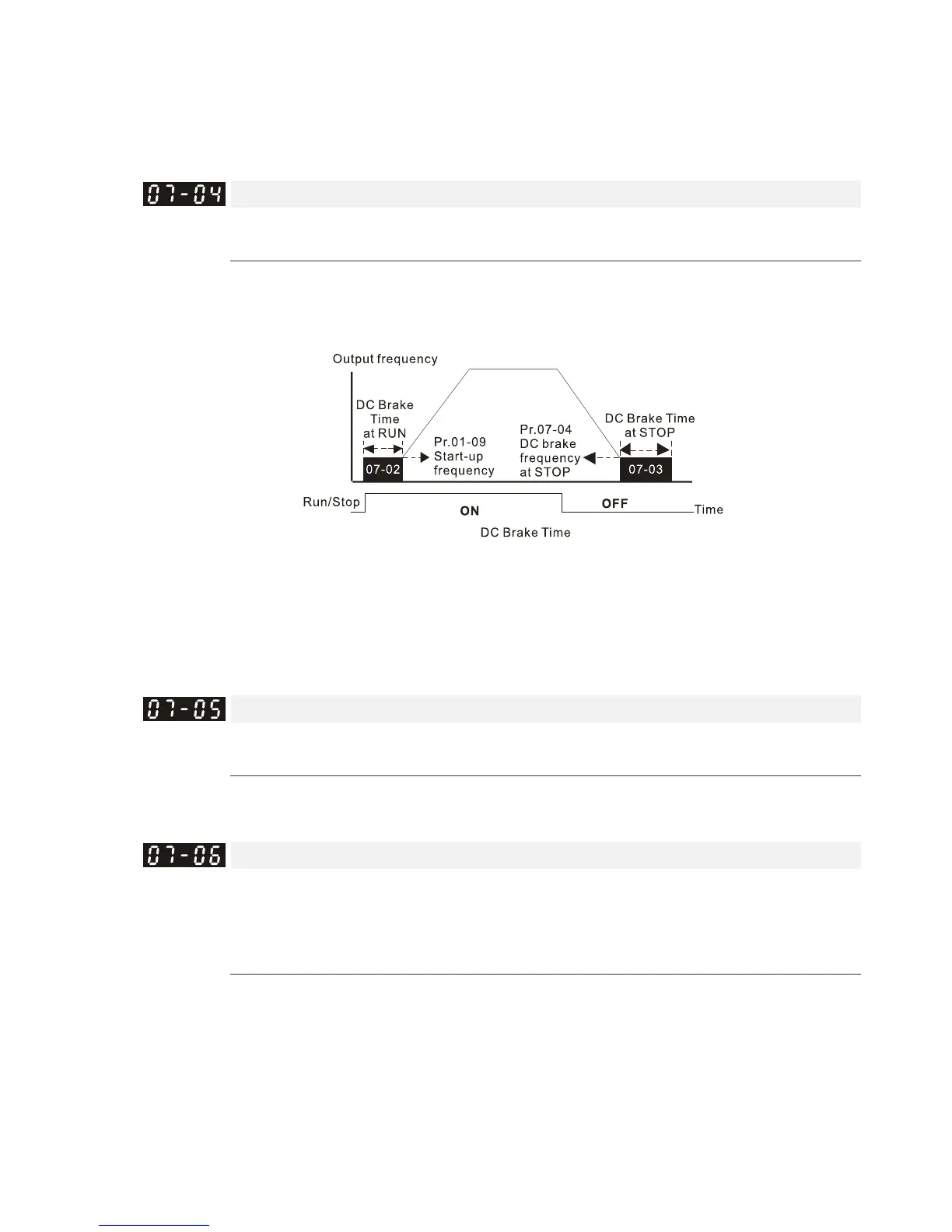

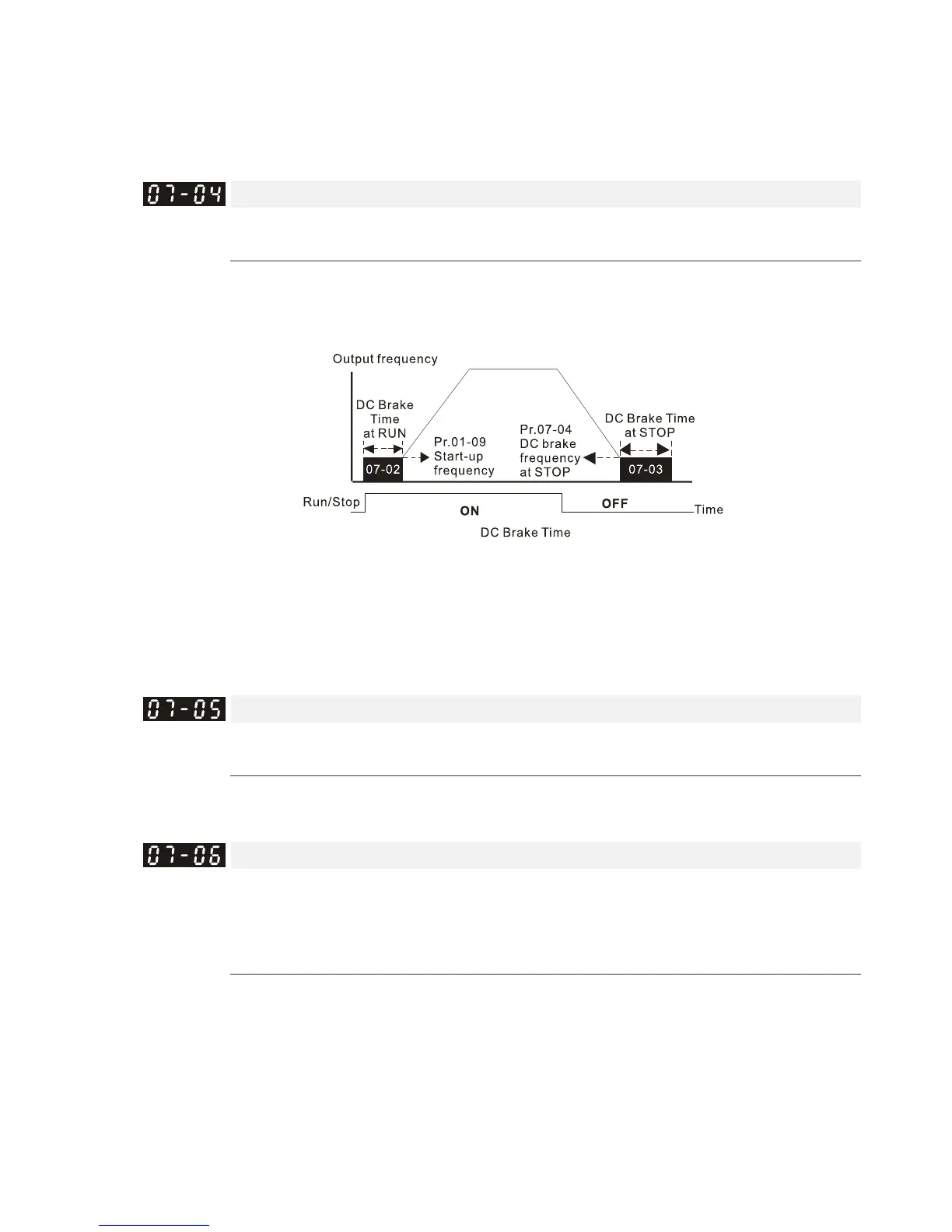

This parameter determines the duration of the DC brake current output to the motor when braking.

To enable DC brake at STOP, set Pr. 00-22 (Stop Method) to 0 (ramp to stop). The DC brake is

invalid when Pr. 07-03 is set to 0.0.

Related parameters: Pr. 00-22 Stop Method, Pr. 07-04 DC Brake Frequency at STOP.

DC Brake Frequency at STOP

Default: 0.00

Settings 0.00–599.00 Hz

This parameter determines the start frequency of the DC brake before the drive ramps to stop.

When this setting is less than Pr.01-09 (Start-up Frequency), the start frequency of the DC brake

starts from the minimum frequency.

Use the DC brake before running the motor when the load is movable at stop, such as with fans

and pumps. The motor is in free operating status and in unknown rotation direction before the

drive starts up. Execute the DC brake before you start the motor.

Use DC Brake at STOP when you need to brake the motor quickly or to control the positioning,

such as with cranes or cutting machines.

Voltage Increasing Gain

Default: 100

Settings 1–200%

When using speed tracking, adjust Pr. 07-05 to slow down the increasing voltage gain if there are

errors such as oL or oc; however, the speed tracking time will be longer.

Restart after Momentary Power Loss

Default: 0

Settings 0: Stop operation

1: Speed tracking by speed before the power loss

2: Speed tracking by minimum output frequency

Determines the operation mode when the drive restarts from a momentary power loss.

The power system connected to the drive may power off momentarily due to many reasons. This

function allows the drive to keep outputting after the drive is repowered and does not cause the

drive to stop.

Setting 1

: Frequency tracking begins before momentary power loss and accelerates to the

master Frequency command after the drive output frequency and motor rotator speed are

synchronous. Use this setting when there is a lot of inertia with little resistance on the motor load.

Loading...

Loading...