DESCRIPTION

20509 Issue 7 Jan 2018 2-7

PRINT HEAD

Ink jet printing does not require contact with the print surface. It is therefore

particularly suitable for printing on rough, irregular, soft or other "difficult"

surfaces.

Macrojet 2 is a valve jet printer. Ink is maintained under pressure behind a

closed nozzle or valve. When the valve is opened for a short time, ink

emerges as a drop and is propelled by the pressure towards the print

surface or substrate. Drops are, therefore, only produced as required in

what is known as Drop-on-Demand printing.

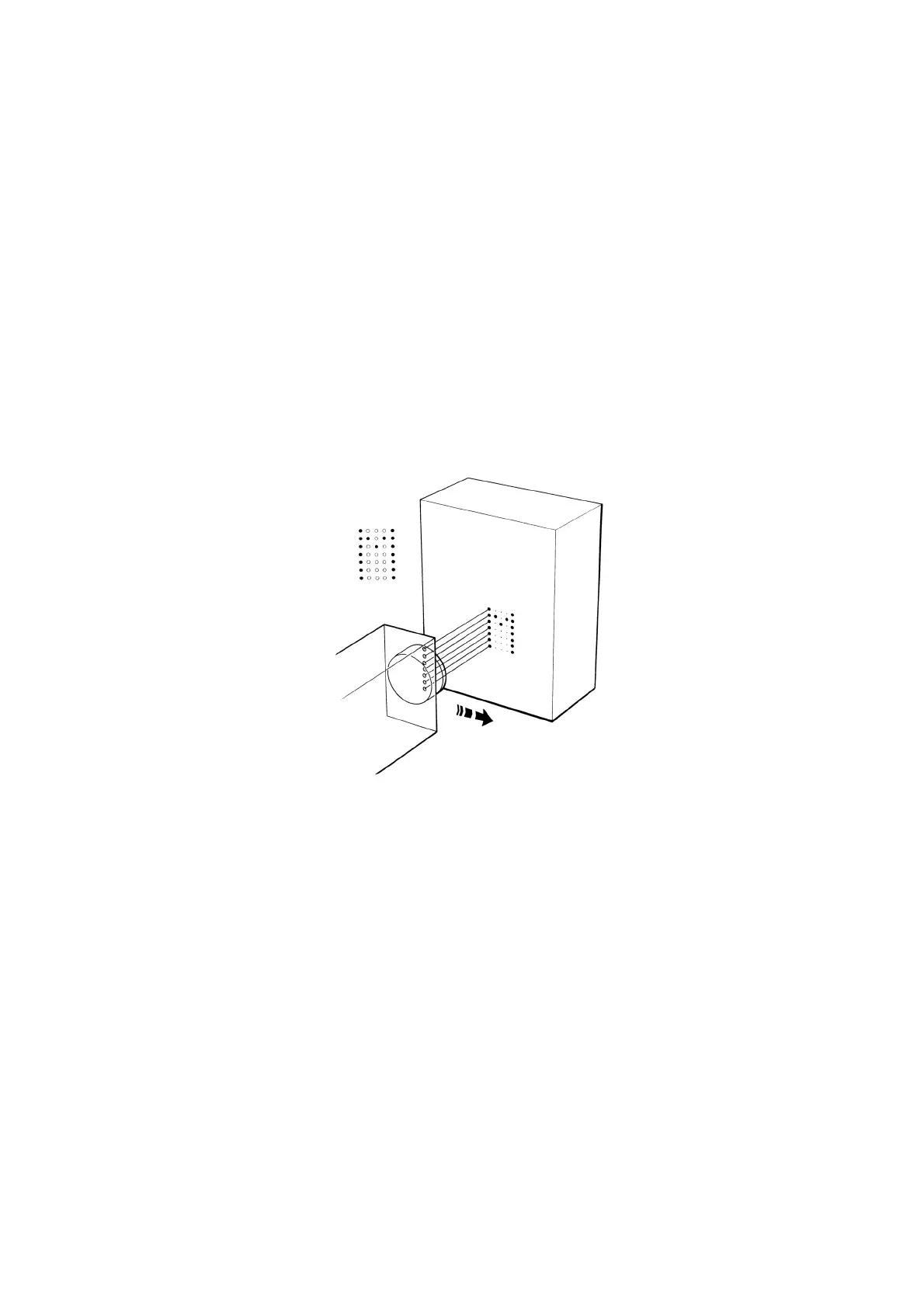

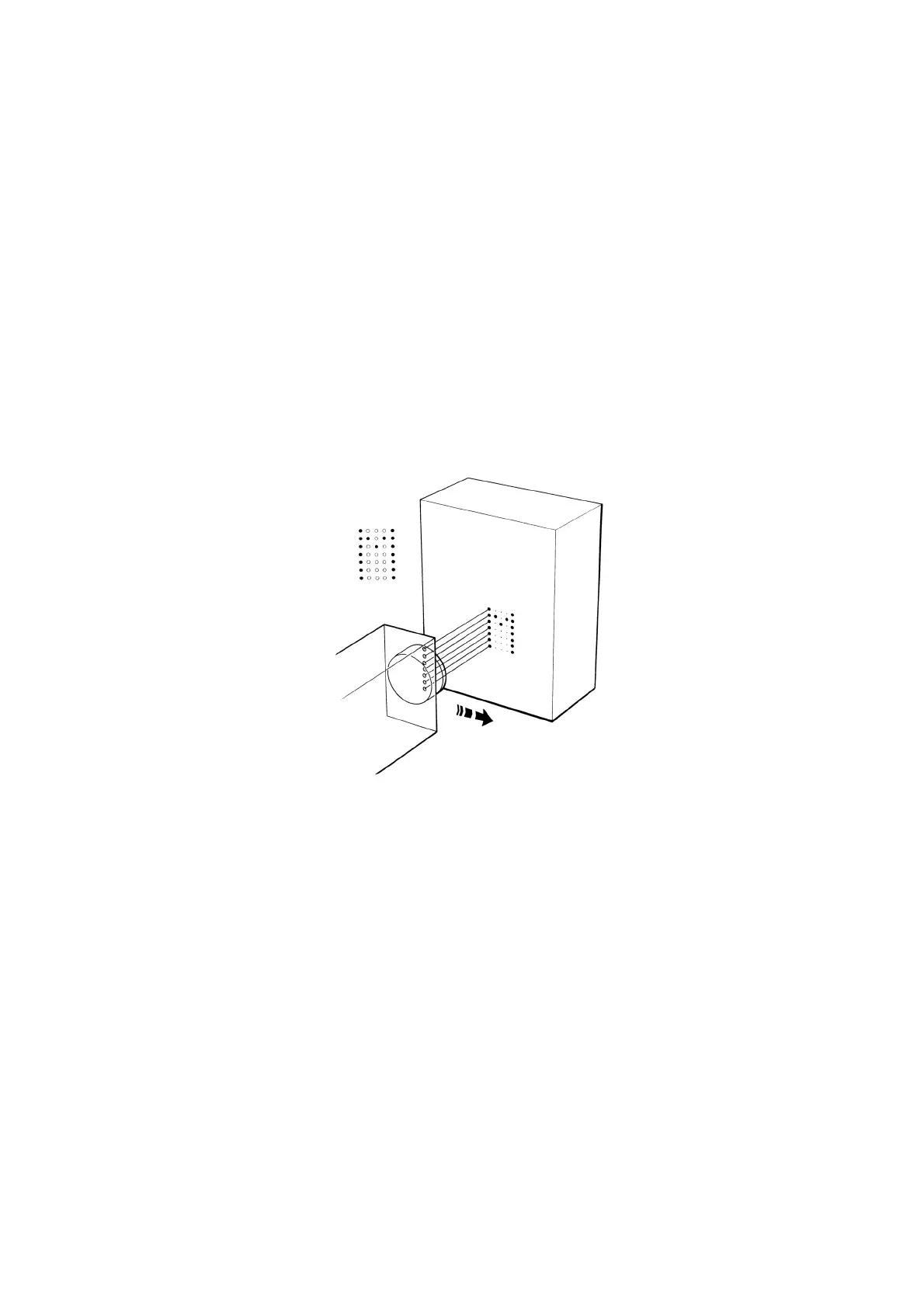

Macrojet 2 print heads have either 7 or 16 nozzles producing a line of drops

called a stroke on the print surface. As the print surface moves past the

head, successive strokes containing different combinations of ink drops

build up the character in the form of a dot matrix. This is best understood

by studying the illustration below.

A dot matrix is specified by the number of dots in a stroke and the number

of strokes making up a single character (for example, the illustration shows

a 7x5 matrix).

The Macrojet print head has, at the front, a nozzle plate with either 7 or 16

nozzles. Ink is supplied under pressure to a manifold behind the nozzle

plate. A plunger, fitted with a rubber slug on its tip, is held against each

nozzle by a spring. The plunger is connected by a wire to a metal slug

sitting part of the way into a solenoid. When the solenoid is energised, the

slug is pulled into the centre of the solenoid. This pulls back the plunger,

opening the nozzle. When the solenoid is de-energised, the spring pushes

the plunger back to close the nozzle.

Loading...

Loading...