Loading...

Loading...

Do you have a question about the Domino Macrojet 2 and is the answer not in the manual?

| Print Resolution | 180 dpi |

|---|---|

| Substrate Compatibility | Porous |

| Connectivity | Ethernet |

| Operating Temperature | 5°C to 40°C |

| Print Technology | Piezo Drop on Demand |

Detailed specifications including print heads, character height, speed, and dimensions.

Details of the ink system, its components, and operation.

Overview of the microprocessor, PCBs, and their functions in the system.

Steps required to fit an additional print head to the printer.

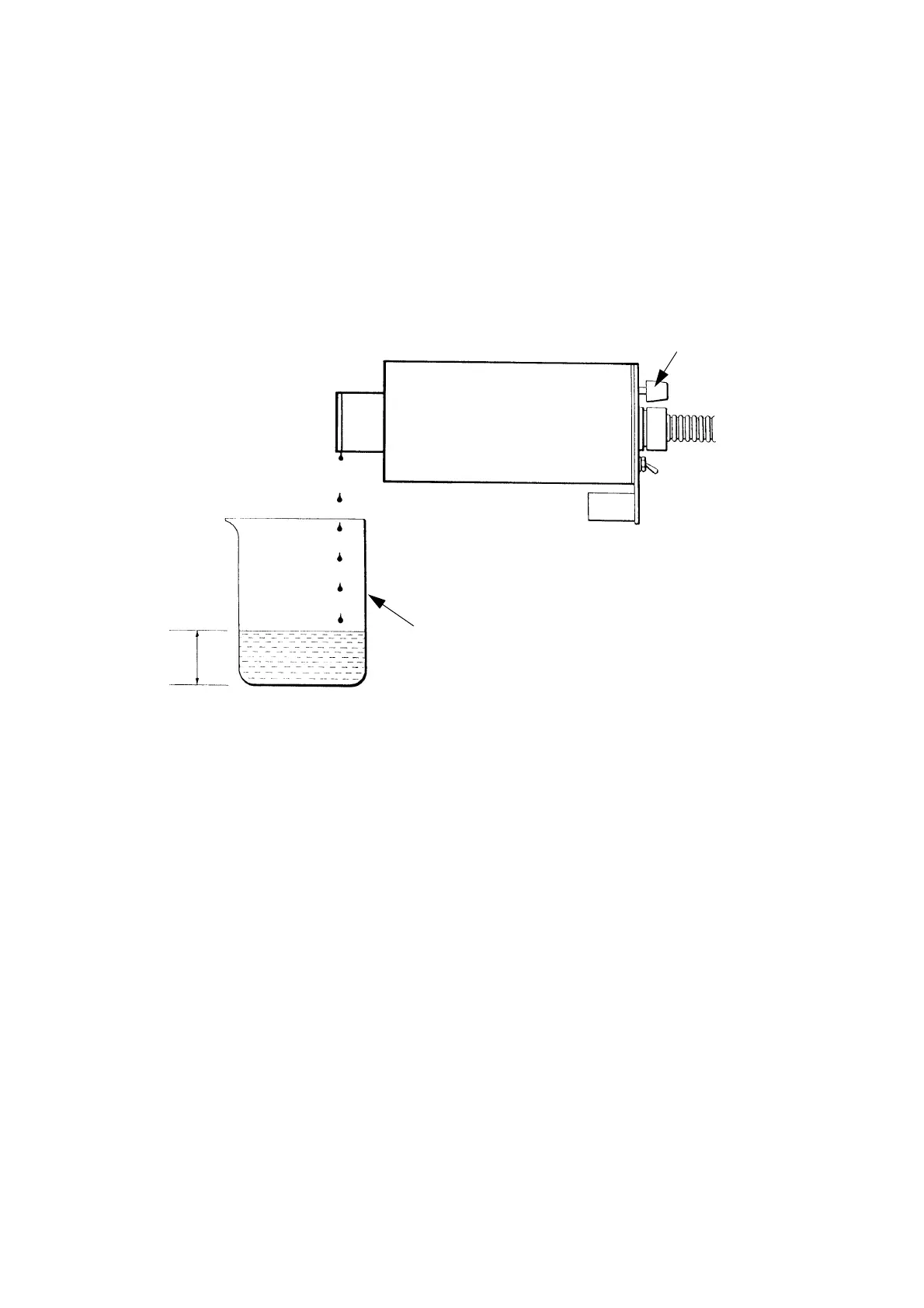

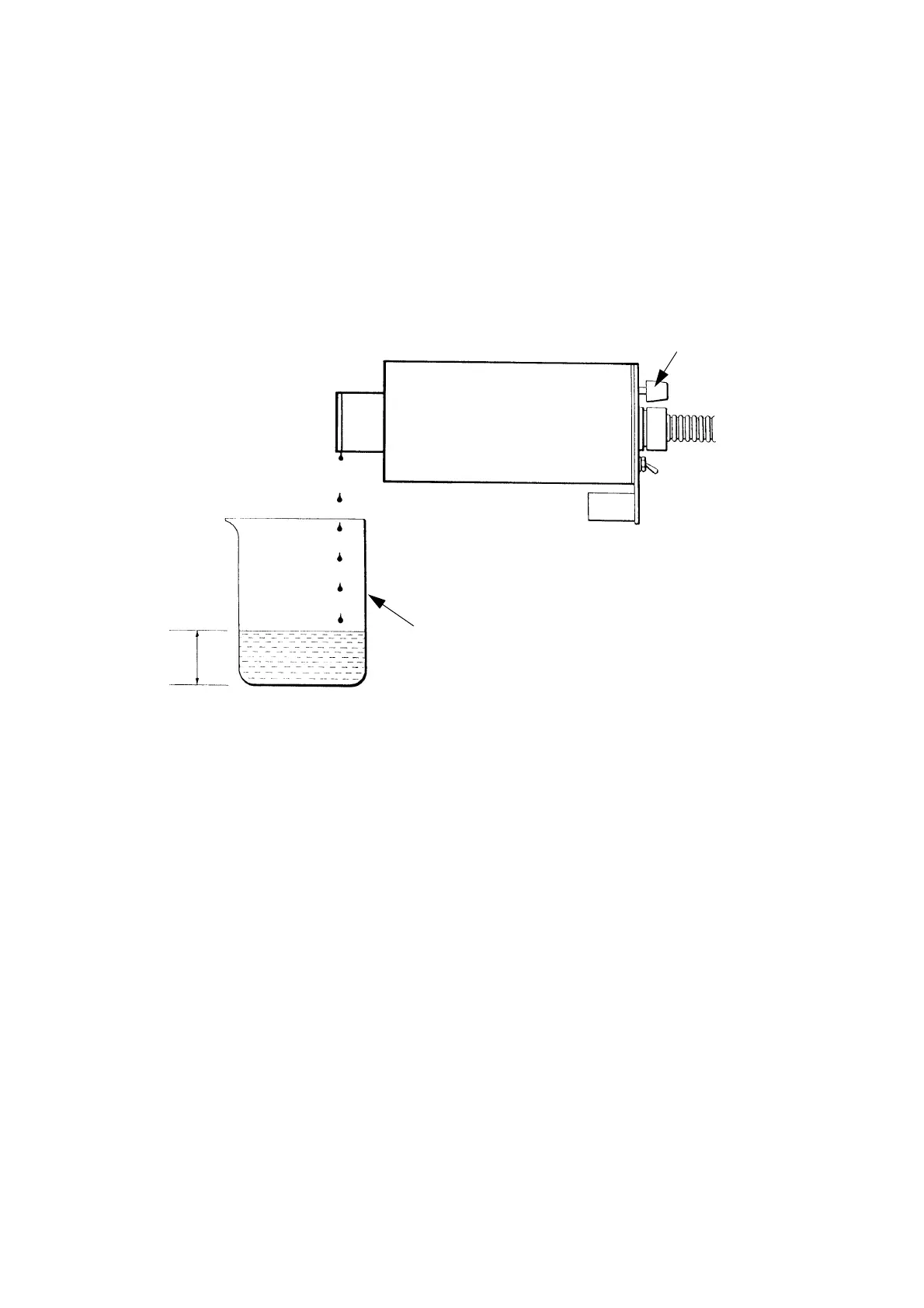

Procedures for checking and adjusting ink drop size for optimal print quality.

Steps for changing inks, including flushing and refilling with different solvent bases.

Guides for identifying and fixing ink system, print head, and electronic faults.

Diagnosing and correcting problems affecting print output quality.

Steps for depressurising, pressurising, priming, and leak checks.

Positioning cabinet, mounting print heads, and electrical supply connection.

Detailed steps for fitting additional print heads and related components.