FAULT FINDING AND REPAIR

20509 Issue 7 Jan 2018 4-25

Pump Replacement

The pump is a reliable unit and before being replaced all other possible

causes of failure to pressurise the system should be investigated. This

includes leaks in the system.

The printer must be switched off and the power removed. Remove the

cabinet cover and place tissue in the cabinet base to catch escaping ink.

(1) Depressurise the ink system.

(2) Note the positions of the wires, then desolder the motor wiring.

(3) Open the bleed valve on the rear panel to vent the system.

(4) Close the bleed valve.

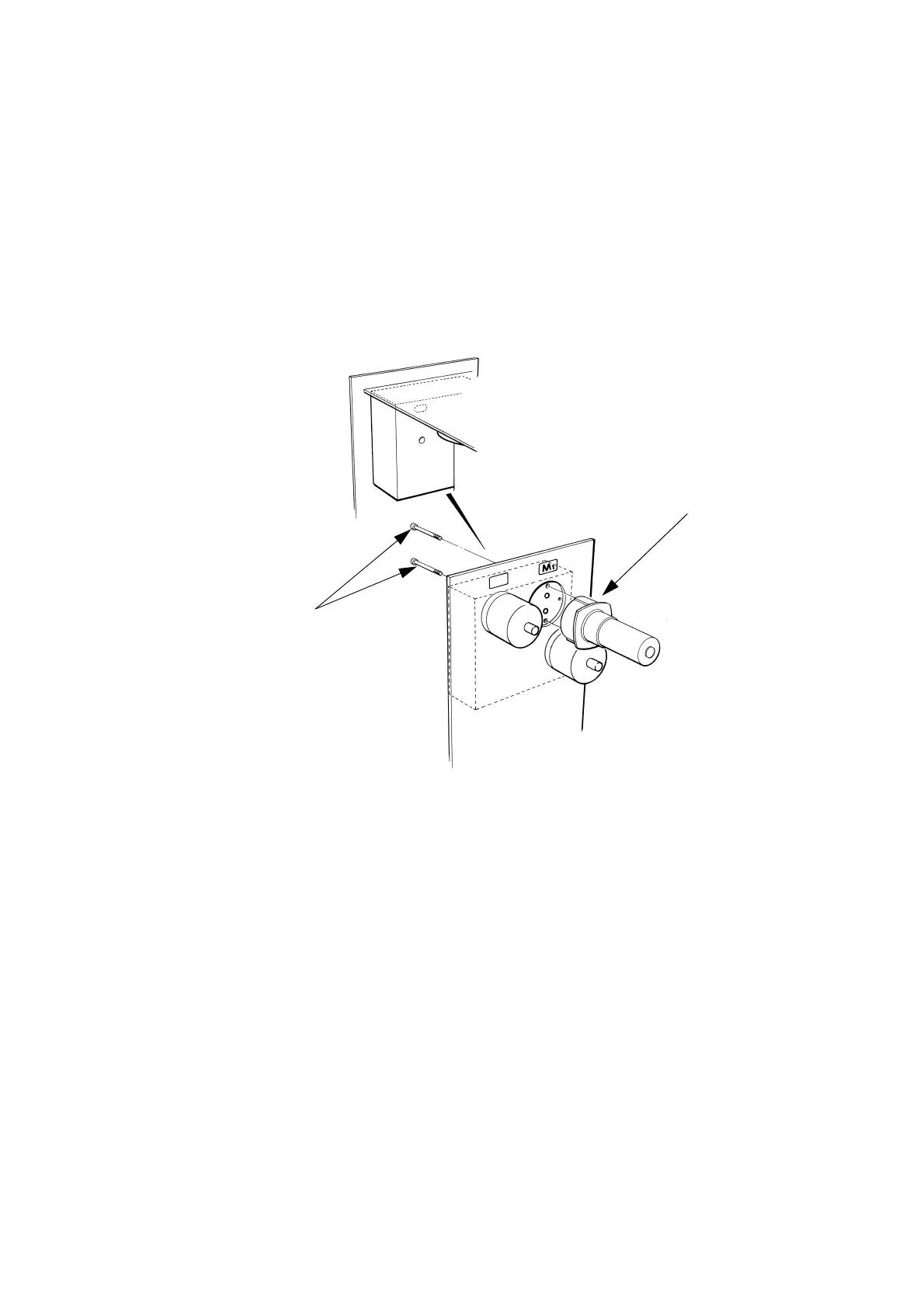

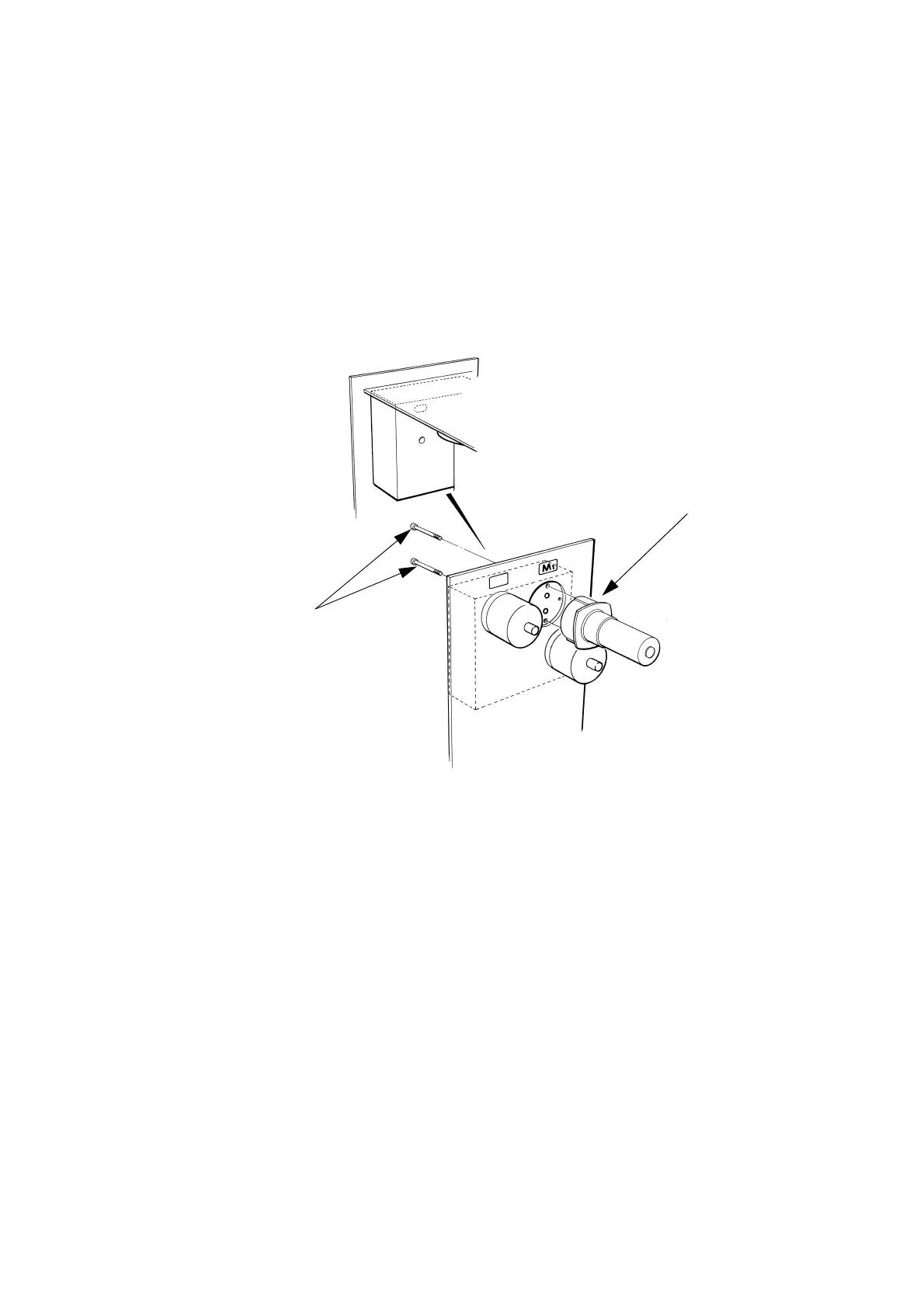

(5) Remove the two cap head screws securing the pump.

Note: The securing screws are in recesses in the accumulator side of

the manifold. They are not the screws around the pump motor

flange. A 2.5mm ball end driver is required for the top screw

and an Allen key for the bottom screw.

(6) Remove the pump and clean pump housing area with wash solution.

(7) Fit new O-Rings into the pump manifold.

(8) Make sure the new pump has a capacitor fitted across the terminals.

(9) Refit the pump to the manifold block.

(10) Resolder motor wiring (violet wire to + terminal).

(11) Prime the system (see page 4-17).

TP33984-2

Securing

Screws

Pump

Loading...

Loading...