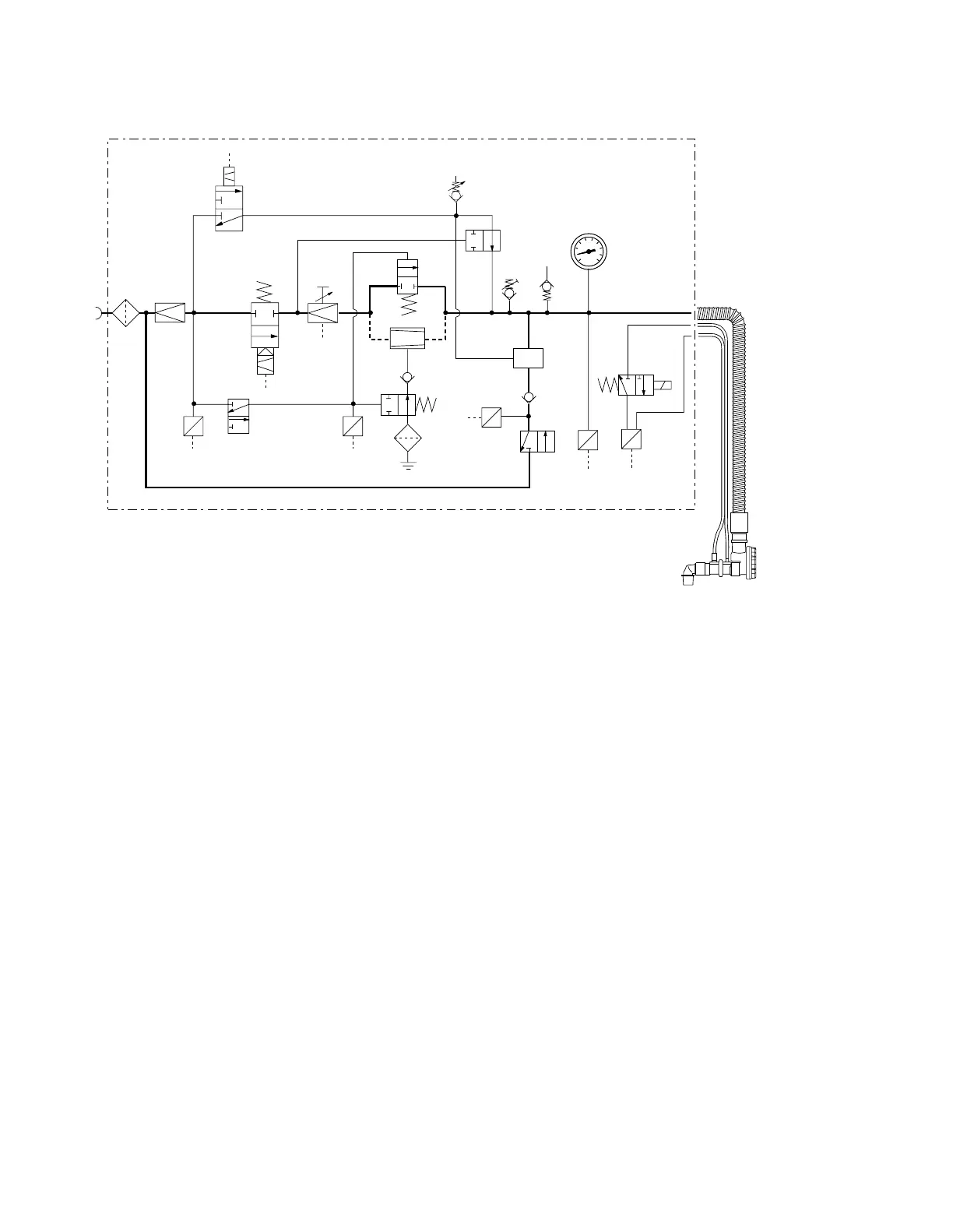

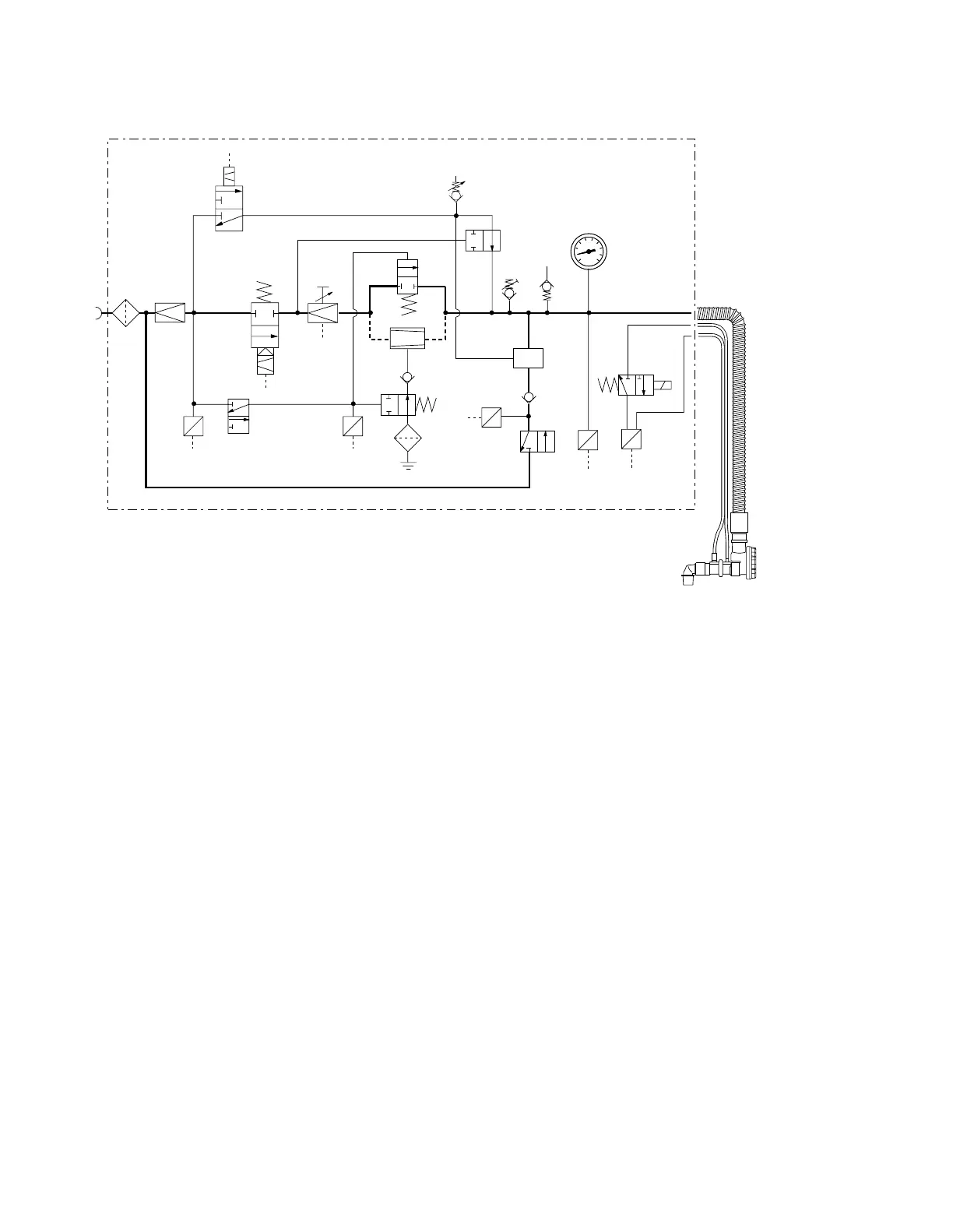

Theory of Operation

Functional Description of Pneumatics

Operating Instructions Oxylog 2000, SW 3.n

58

P

E

P

E

E

P

P

E

∆P

E

PEEP

Paw

Paw

Flow

15

14

13

24

2322

6

25 26

5

IPPV/

SIMV/CPAP

4

21

87

10

O

2

AIR

12

3

9

11

12

17

18

19

20

16

Insp./Exsp.

Air Mix/

No Air Mix

100%O

2

50%O2

27

04329033

Insp./Exp.

Automatic zeroing of differential pressure sensor 26 is

performed with 3/2-way valve 27.

3/2-way magnetic valve 3 interrupts gas flow either in a

time cycled fashion after inspiratory time (set via rate and

I:E ratio) has elapsed, or pressure cycled after preset

pressure Pmax has been reached.

Expiration/PEEP

Gas in the patient circuit 13 is released via 2/2-way valve

21 down to the end-expiratoy pressure set with »PEEP«

valve 8. The patient can exhale through flow sensor 15

and patient valve 14 to ambient air. Patient valve 14 will

maintain PEEP pressure set with »PEEP« valve 8.

CPAP

3/2-way valve 4 releases gas flow to demand valve 6.

This function is monitored by pressure sensor 5.

Inspiration/ Expiration

Demand valve 6 delivers an appropriate volume to the

patient controlled by patient inspiratory effort. Gas delive-

ry is stopped when the patient wants to exhale.

The demand valve maintains CPAP pressure in the brea-

thing circuit using the PEEP/CPAP set with »PEEP«

valve 8.

CMV / SIMV / A/C

Inspiration

3/2-way magnetic valve "Insp./Exp." 3 releases gas flow.

Gas flow is controlled via electrically operated flow valve

10 and reaches the patient circuit either via 2/2-way val-

ve 11 or via injector 12. From there, gas is supplied to

the patient wye passing through patient valve 14 and flow

sensor 15.

Dependent on the position of 3/2-way valve 16, O2 is

supplied at 100% or is diluted to 60%. In order to

perform blending, injector 12 draws ambient air via non-

return valve 17, 2/2-way valve 18 and filter 19.

Pressure sensor 20 monitors position of

»Air Mix/No Air Mix« switch.

The controlled 2/2-way valve 21 prevents inspiratory gas

to reach the »PEEP« valve 8. Pressure limiting valve 22

limits inspiratory pressure to a maximum value indepen-

dent of Pmax setting.

Additional ambient air can be drawn through auxiliary

valve 23 in cases of failed gas supply. Airway pressure is

measured at pressure gauge 24 and pressure

sensor 25.

Expiratory flow creates a proportional differential pressu-

re at flow sensor 15 which is measured by differential

pressure sensor 26 and used to determine minute venti-

lation.

CMV / A/C

SIMV / CPAP

Loading...

Loading...