Section 6: Troubleshooting

CAUTION:

This actuator is non-intrusive. Do not open the control compartment on the actuator

unless absolutely necessary. It was sealed in dry-clean conditions in the factory and

entry into this compartment should not be necessary. Unauthorized entry could void

the warranty.

6.1 Troubleshooting Problems/Corrective Action

for Actuator Operation

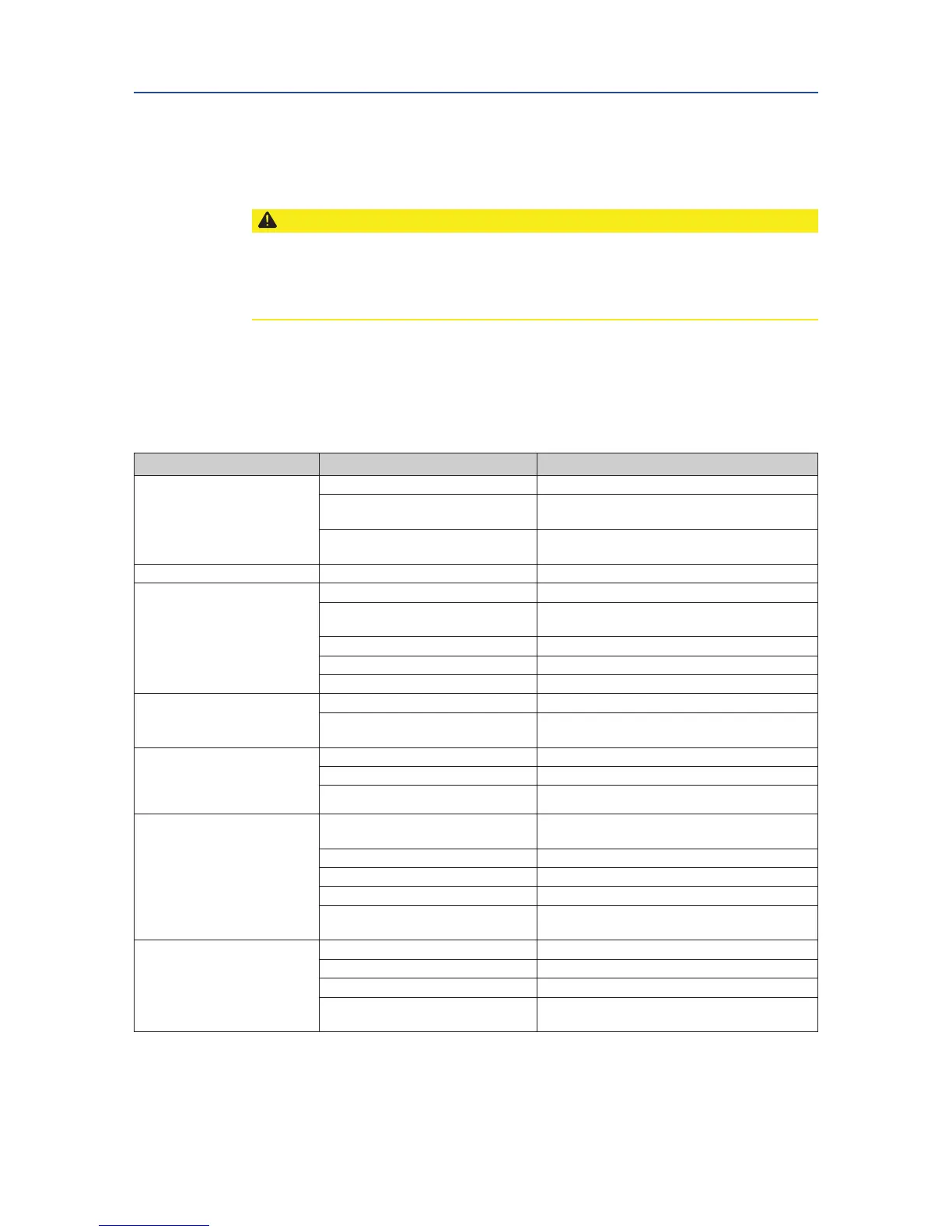

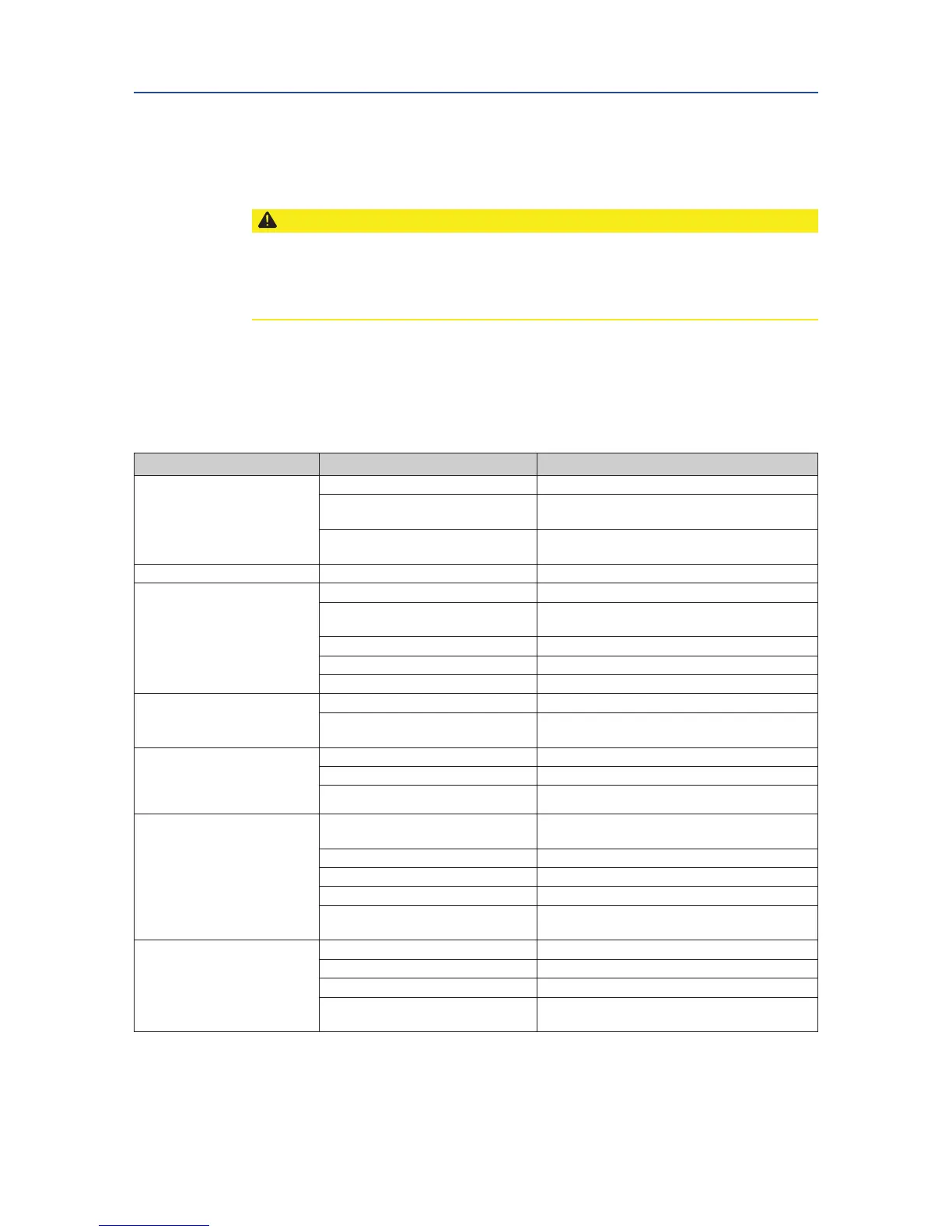

Symptom Probable Cause Corrective Action

Motor will not Run

Blown Control Fuse Check Fuse and Replace as necessary

Open in Control Circuit

Refer to appropriate wiring diagram and check

for continuity

Insulation Resistance Breakdown in

Motor

Perform Megger Test

No Power available to Actuator Tripped Circuit Breaker Reset Circuit Breaker

Handwheel Hard to Turn

Valve Stem improperly Lubricated Lubricate with Grease

Actuator Lubrication has broken

down

Clean out old grease and replace with

recommended lubricant

Valve packing gland too tight Loosen packing gland nuts as necessary

Drive Sleeve Bearing Failure Replace Bearing

Jammed Valve Refer to Valve Maintenance

Valve only opens or closes

partially with motor

Torque Switch Setting too low Check Setting and Reset if necessary

Limit Switch Improperly Set

Check Switch Actuation and re-calibrate if

necessary

Torque switch is properly set,

but actuator Torque’s out in

mid-travel, open or closed

direction

Damaged or bent valve stem Refer to Valve Maintenance

Valve packing too tight Refer to Valve Maintenance

Jammed Valve (obstruction in line) Refer to Valve Maintenance

Handwheel will not operate

valve

Handwheel shaft bearing assembly

malfunction

Repair or replace as necessary

Sheared gear key or Stripped Gearing Replace as necessary

PS Shifter Position or Malfunction Replace Gear(s)

Broken Handwheel Shaft Repair or replace as necessary

Broken Valve Stem or Stripped Stem

Nut

Repair or replace as necessary

Motor runs but will not operate

the valve

Motor Bearing Assembly Malfunction Repair or replace as necessary

Sheared gear key (fastener pin) Replace

Stripped Gearing Replace

Broken Valve Stem or Stripped Stem

Nut

Repair or replace as necessary

If the LDM does not receive communication messages from the CCM within 5 seconds after power is applied

or loses communication for 5 seconds or more, it will display a ashing message "CCM LINK FAILED" and

blink all three LEDs.

Loading...

Loading...