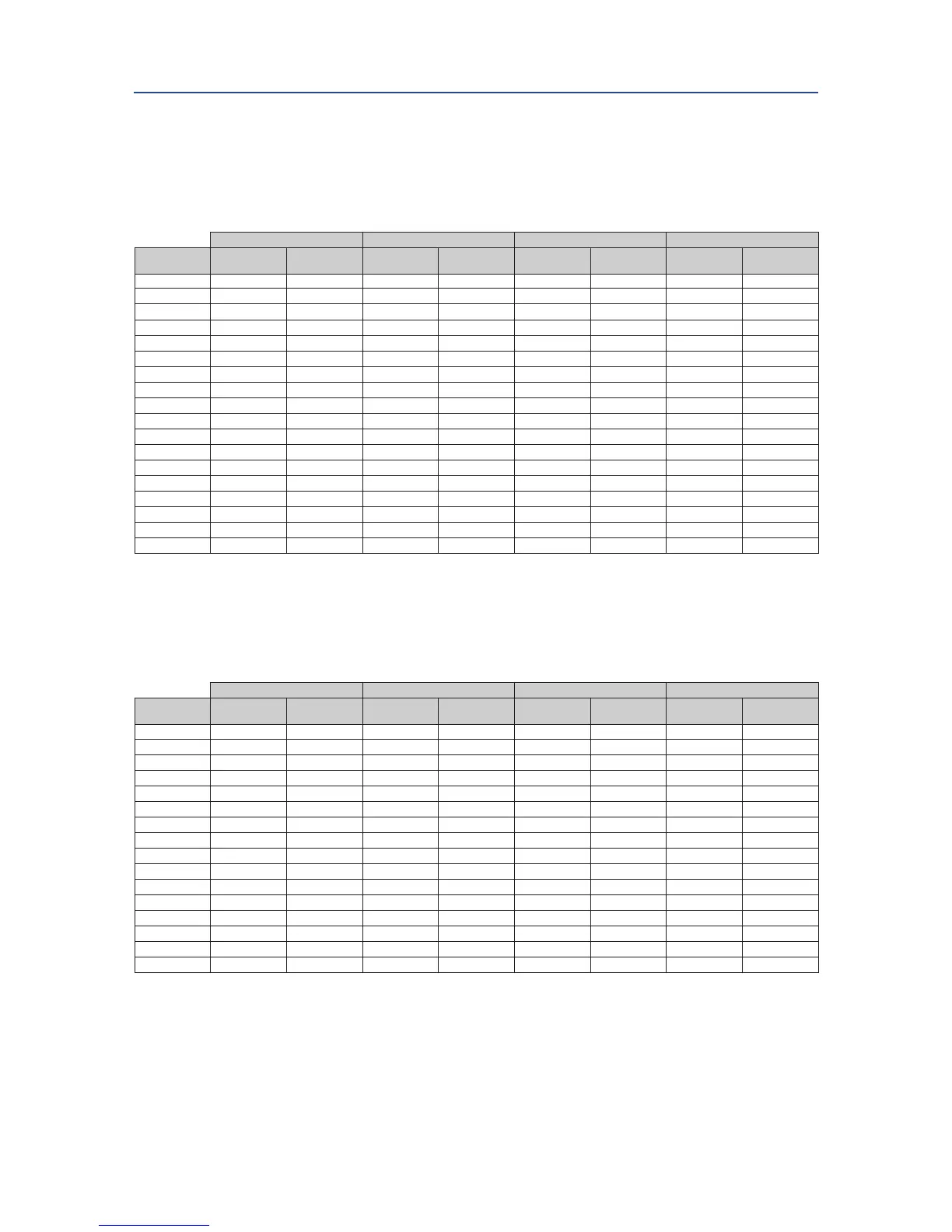

A.7 Common Bolt Tightening Torques

Grade 1 Grade 2 Grades 5, 5.2 & 5.1 Grades 8, 8.1 & 8.2

Thread Size &

Pitch

Clamp Load (lb)

Tightening

Torque (ft-lb)

Clamp Load (lb)

Tightening

Torque (ft-lb)

Clamp Load (lb)

Tightening

Torque (ft-lb)

Clamp Load (lb)

Tightening

Torque (ft-lb)

6 - 32 225 0.52 375 0.86 579 1.33 818 1.88

8 - 32 347 0.95 578 1.58 893 2.44 1260 3.44

10 - 24 433 1.37 722 2.29 1116 3.53 1575 4.99

12 - 24 599 2.16 998 3.59 1543 5.55 2178 7.84

1/4 - 20 787 3.28 1312 5.47 2027 8.45 2862 11.9

5/16 -18 1297 6.75 2162 11.3 3341 17.4 4716 24.6

3/8 - 16 1918 12.0 3197 20.0 4941 30.9 6975 43.6

7/16 - 14 2631 19.2 4385 32.0 6777 49.4 9567 69.8

1/2 - 1 3 3512 29.3 5853 48.8 9046 75.4 12771 106

9/16 - 12 4505 42.2 7508 70.4 11603 109 16380 154

5/8 - 11 5594 58.3 9323 97.1 14408 150 20340 212

3/4 - 10 8267 103 8267 103 21293 266 30060 376

7/8 - 9 11435 167 11435 167 29453 430 41580 606

1- 8 14999 250 14999 250 33633 561 54540 909

1-1/8 - 7 18884 354 18884 354 42347 794 68670 1288

1-1/4 - 7 23983 500 23983 500 53780 1120 87210 1817

1-3/8 - 6 28586 655 28586 655 64103 1469 103950 2382

1-1/2 - 6 34774 869 34774 869 77978 1949 126450 3161

English Units: (Coarse Thread Series)

Tightening Torque = K * D * P

K = 0.2 (dry, unlubricated)

Clamp Load (P) = 75% of the Proof Load

D = Nominal Thread Size

The values presented in these tables are representative and have been compiled for the user’s benet. Results can be inuenced by

any number of variables including 1) excessive lubrication, 2) excessive design clamp load, 3) nicked or binding threads, 4) non-parallel

mating surfaces, and 5) inadequate torque control, to name a few. Therefore, Load expressly disclaims liability of any kind associated with

the application of the data shown herein.

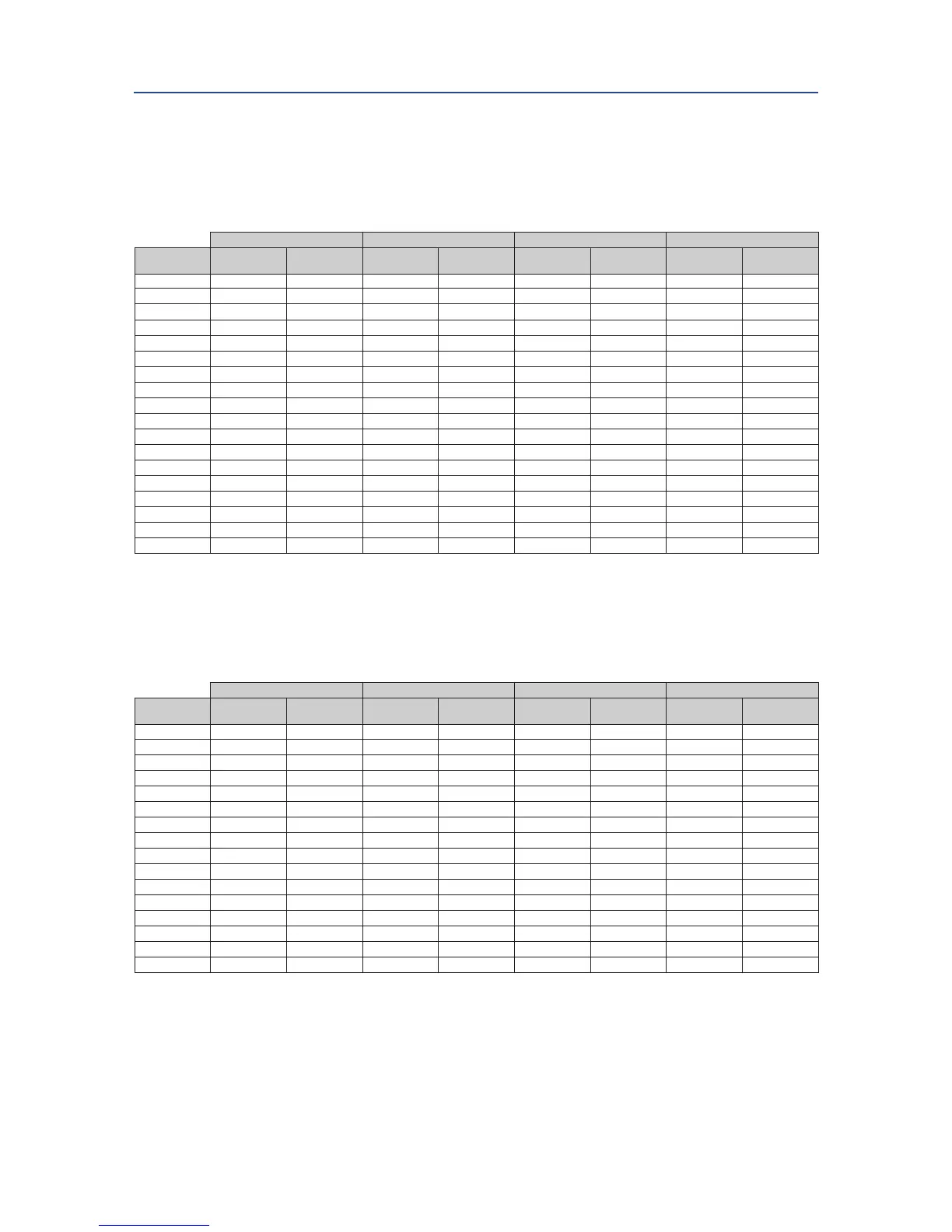

Class 4.6 Class 5.8 Class 9.8 Class 10.9

Thread Size &

Pitch

Clamp Load (KN)

Tightening

Torque (N*m)

Clamp Load (KN)

Tightening

Torque (N*m)

Clamp Load (KN)

Tightening

Torque (N*m)

Clamp Load (KN)

Tightening

Torque (N*m)

M6 X 1 3.41 4.09 5.73 6.87 9.80 11.76 12.5 15

M7 X 1 4.90 6.86 8.24 11.5 14.1 19.72 18.0 25

M8 X 1.25 6.20 9.93 10.4 16.7 17.8 28.55 22.8 36

M10 X 1.5 9.8 19.7 16.5 33.1 28.3 56.55 36.1 72

M12 X 1.75 14.3 34.3 24.0 57.7 41.1 98.63 52.5 126

M14 X 2 19.5 54.6 32.8 91.8 56.1 157 71.6 200

M16 X 2 26.6 85.2 44.7 143 76.5 245 97.7 313

M18 X 2.5 32.5 117 54.7 197 93.6 337 120 430

M20 X 2.5 41.5 166 69.8 279 119 478 153 610

M22 X 2.5 51.4 226 86.4 380 148 650 189 830

M24 X 3 59.8 287 101 483 172 826 220 1055

M27 X 3 77.8 420 131 706 224 1208 286 1543

M30 X 3.5 95.1 571 160 959 273 1641 349 2095

M33 X 3.5 118 776 198 1305 338 2233 432 2851

M36 X 4 138 997 233 1676 398 2868 509 3662

M39 X 4 165 1290 278 2170 476 3711 608 4739

Metric Units: (Coarse Thread Series)

Tightening Torque = K * D * P

K = 0.2 (dry, unlubricated)

Clamp Load (P) = 75% of the Proof Load

D = Nominal Thread Size

Loading...

Loading...