Safety

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

20 Digitax ST User Guide

Issue: 5

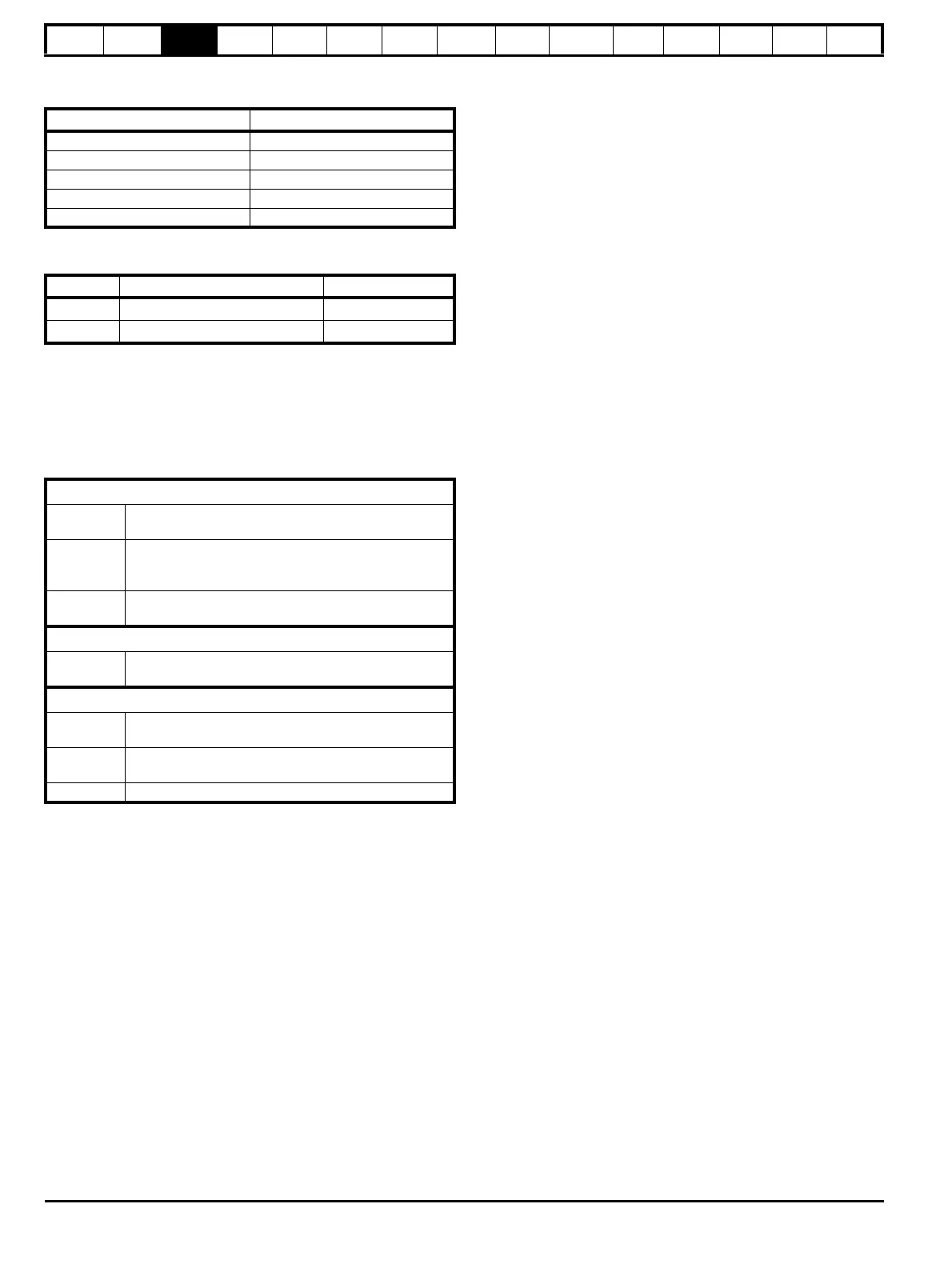

3.7 Terminal torque settings

Table 3-2 Torque settings

*Torque tolerance = 10 %

Table 3-3 Plug-in terminal block maximum cable sizes

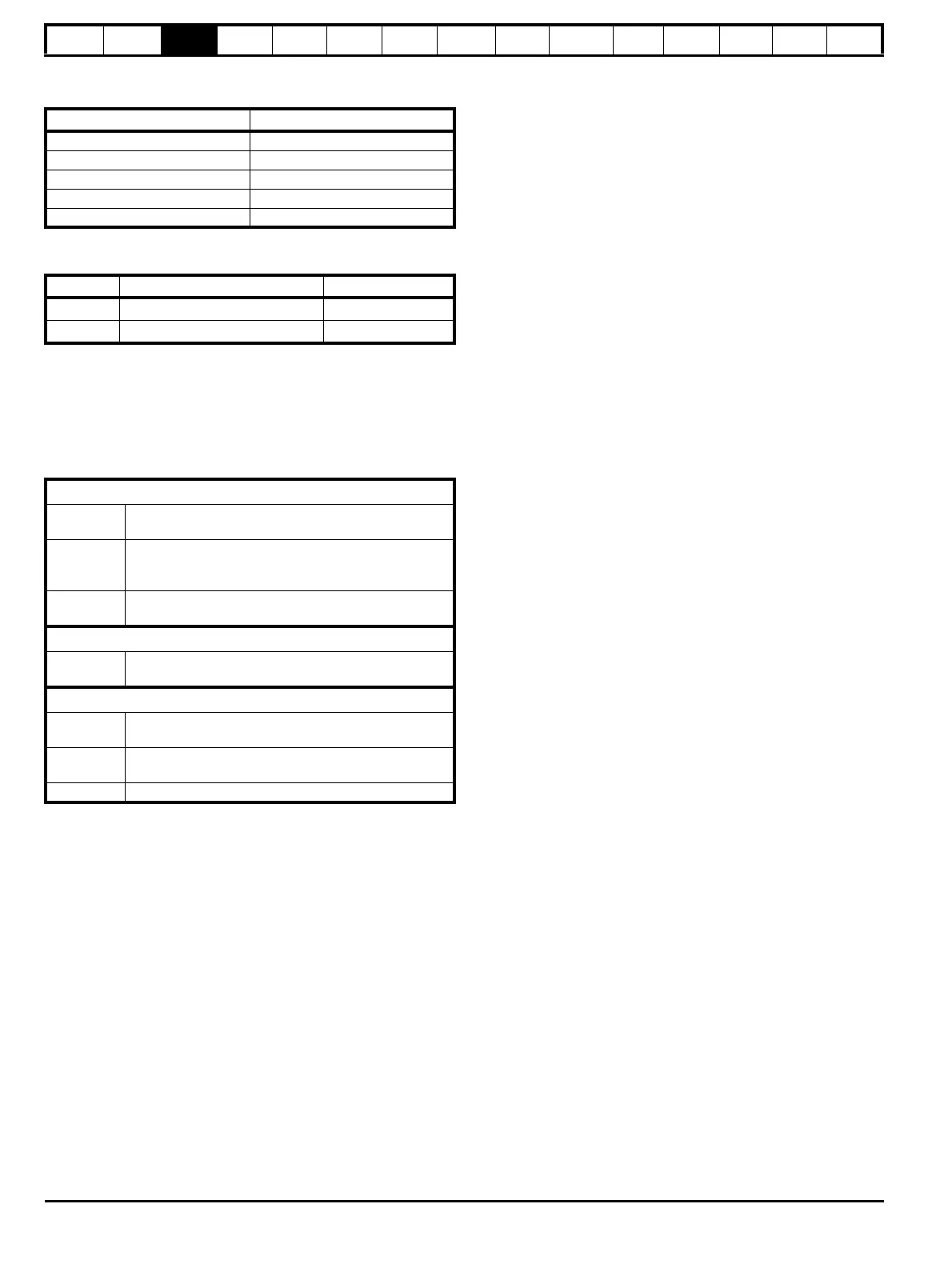

3.8 Routine maintenance

The drive should be installed in a cool, clean, well ventilated location.

Contact of moisture and dust with the drive should be prevented.

Regular checks of the following should be carried out to ensure drive /

installation reliability are maximized:

Terminals Torque setting*

Power terminals 1.0 N m (12.1 lb in)

Control terminals 0.2 N m (1.7 lb in)

Status relay terminals 0.5 N m (4.5 lb in)

Ground terminals 4 N m (35 lb in)

Small ground terminal screws 2 N m (17.7 lb in)

Model size Terminal block description Max cable size

All 11 way control connectors

1.5 mm

2

(16 AWG)

All 2 way relay connector

2.5 mm

2

(12 AWG)

Environment

Ambient

temperature

Ensure the enclosure temperature remains at or below

maximum specified

Dust

Ensure the drive remains dust free – check that the

heatsink and drive fan are not gathering dust. The

lifetime of the fan is reduced in dusty environments.

Moisture

Ensure the drive enclosure shows no signs of

condensation

Enclosure

Enclosure

door filters

Ensure filters are not blocked and that air is free to flow

Electrical

Screw

connections

Ensure all screw terminals remain tight

Crimp

terminals

Ensure all crimp terminals remains tight – check for any

discoloration which could indicate overheating

Cables Check all cables for signs of damage

Loading...

Loading...