Safety

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

24 Digitax ST User Guide

Issue: 5

4.4 DC bus design

4.4.1 DC bus design

Parallel connections

The power limit of the rectifier must be adhered to for all combinations of

drives in parallel. In addition to this If the total rated bus power required

exceeds the capability of 1 x Digitax ST rectifier then two or more Digitax

ST's can be connected with the AC & DC in parallel. If the AC supply is

connected to more than one drive in a parallel DC bus application,

balancing of the current in the input stage of each drive must be

considered.

Using DC bus chokes makes the current in the rectifier diodes of each

drive the same, so providing a solution to sharing.

There are many possible combinations for paralleling drives through the

DC bus connections. Table 4-3 gives details of the internal capacitance

for each drive and the additional capacitance which can be powered

from the drive. The capacitance must incorporate its own soft-start

circuit. All Digitax ST drives incorporate this feature.

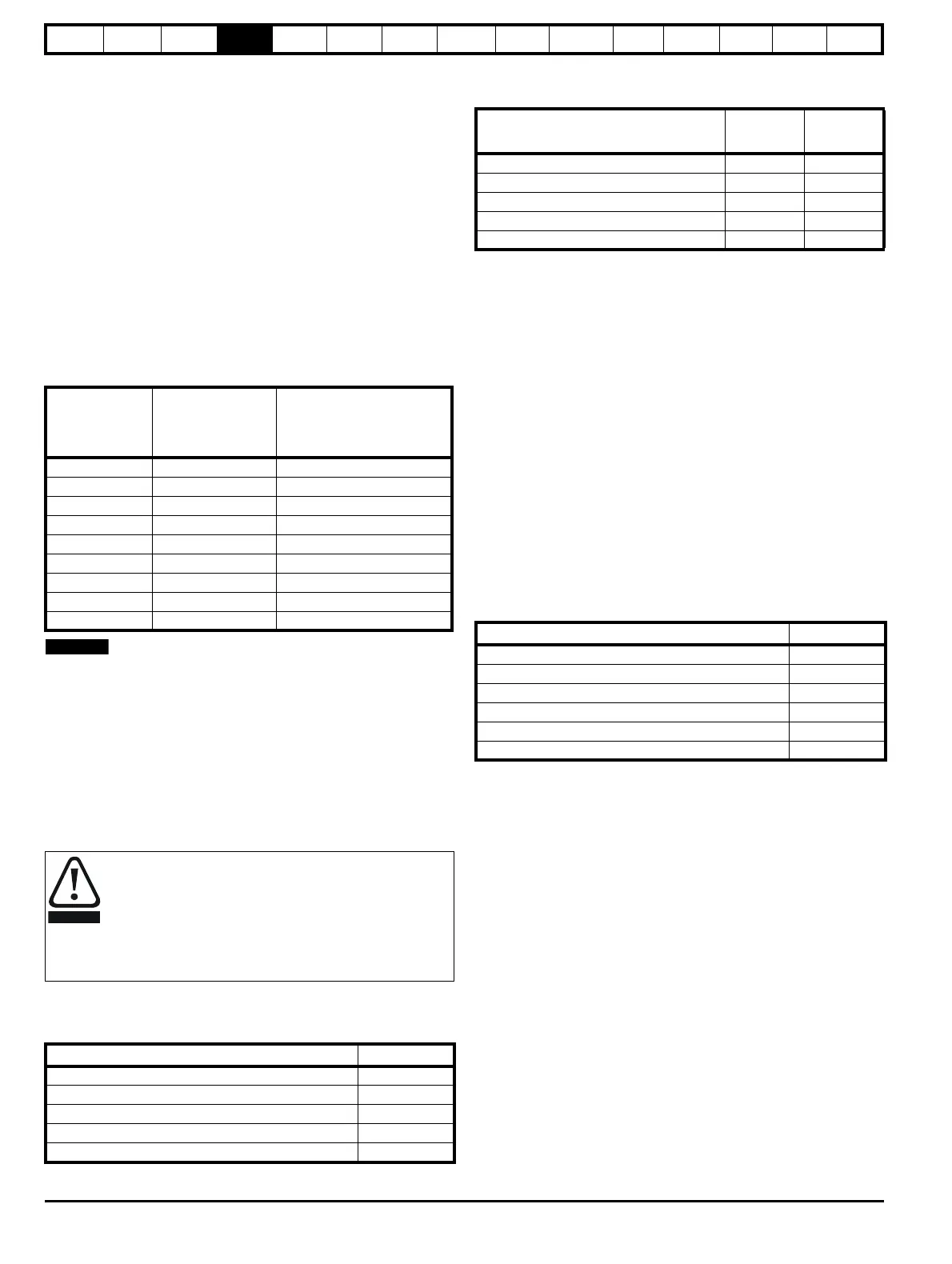

Table 4-3 DC bus data

For additional details regarding DC bus paralleling please contact the

supplier of the drive.

4.5 DC drive voltage levels

4.5.1 Low voltage DC operation

The drive can be operated from low voltage DC supplies, nominally 24

Vdc (control) and 48 Vdc (power). The low voltage DC power operating

mode is designed either, to allow for motor operation in an emergency

back-up situation following failure of the AC supply, for example in

robotic arm applications; or to limit the speed of a servo motor during

set-up of equipment, for example a robot cell.

The working voltage range of the low voltage DC power supply is shown

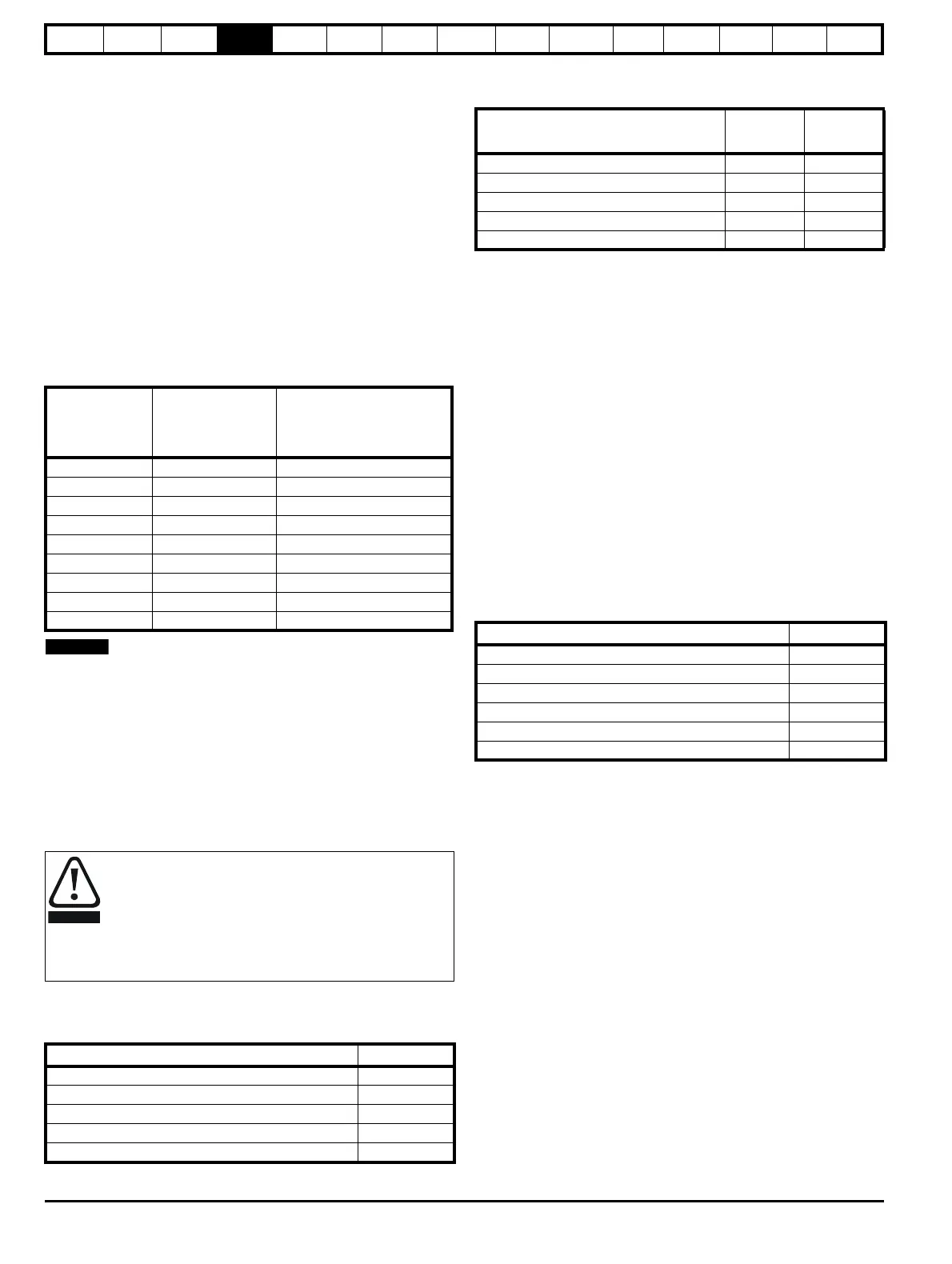

in Table 4-4.

Table 4-4 Low voltage DC levels

4.5.2 High voltage DC levels

Table 4-5 High voltage DC levels

* These are the absolute minimum DC voltages that the drive is capable

of operating from. If the drive is not supplied with the minimum voltage, it

will not reset following a UV trip at power-up.

4.5.3 Control 24 Vdc supply

The 24 Vdc input has three main functions:

• It can be used as a back-up power supply to keep the control circuits

of the drive powered up when the line power supply is removed. This

allows any fieldbus modules or serial communications to continue to

operate.

• It can be used to supplement the drive’s own internal 24 V when

multiple SM-I/O Plus modules are being used and the current drawn

by these modules is greater than the drive can supply. (If too much

current is drawn from the drive, the drive will initiate a 'PS.24V' trip)

• It can be used to commission the drive when line power supply

voltages are not available, as the display operates correctly.

However, the drive will be in the UV trip state unless either line

power supply is reapplied or low voltage DC operation is enabled,

therefore diagnostics may not be possible. (Power down save

parameters are not saved when using the 24 V back-up power

supply input.)

The working voltage range of the 24 V power supply is shown in Table 4-6.

Table 4-6 Control supply voltage levels

Minimum and maximum voltage values include ripple and noise. Ripple

and noise values must not exceed 5 %.

Drive

Internal DC bus

capacitance

(μF)

Maximum additional DC

bus capacitance which can

be connected

(μF)

DST1201 440 1760

DST1202 880 1320

DST1203 880 1320

DST1204 1320 880

DST1401 220 660

DST1402 220 660

DST1403 220 660

DST1404 220 660

DST1405 220 660

With low voltage DC operation there is a reduction in the

level of safety of the Safe Torque Off function. There

exist certain unlikely faults which might permit the drive to

produce some limited motor torque, if the DC supply has its

negative terminal connected to ground.

See section 4.17 Safe Torque Off on page 42 for methods

on preventing a loss of the safety function under these

conditions.

Condition Value

Minimum continuous operating voltage 36 V

Minimum start up voltage 40 V

Nominal continuous operating voltage 48 V to 72 V

Maximum braking IGBT turn on voltage 63 V to 95 V

Maximum over voltage trip threshold 69 V to 104 V

Condition

DST120X DST140X

VV

Undervoltage trip level 175 330

Undervoltage reset level* 215 425

Overvoltage trip level 415 830

Braking level 390 780

Maximum continuous voltage level for 15 s 400 800

Condition Value

Maximum continuous operating voltage 30.0 V

Minimum continuous operating voltage 19.2 V

Nominal operating voltage 24.0 V

Minimum start up voltage 21.6 V

Maximum power supply requirement at 24 V 60 W

Recommended fuse 3 A, 50 Vdc

Loading...

Loading...