Emerson Process Management GmbH & Co. OHG1-18

X-STREAM XE

Instruction Manual

HASXEE-IM-HS

05/2017

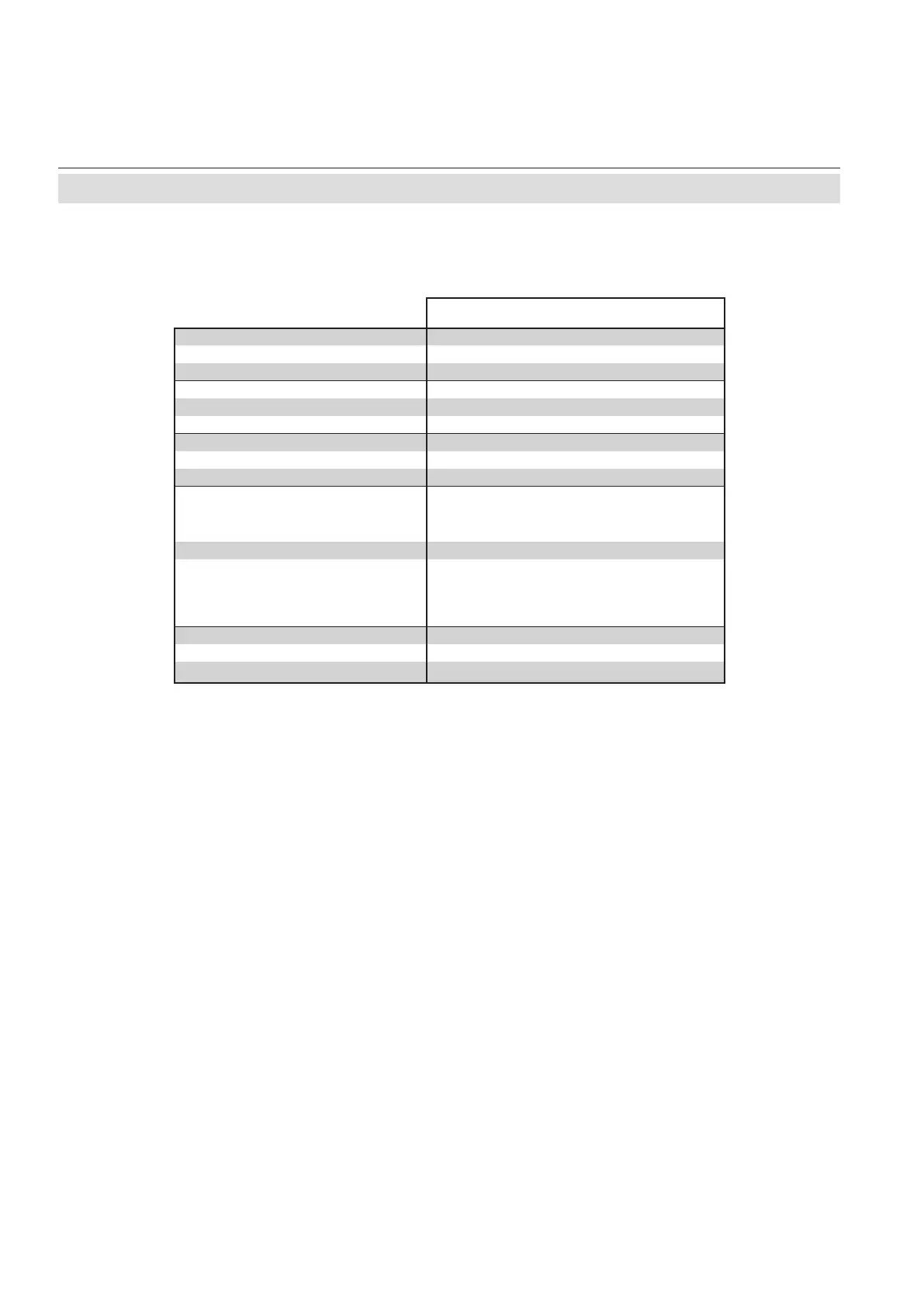

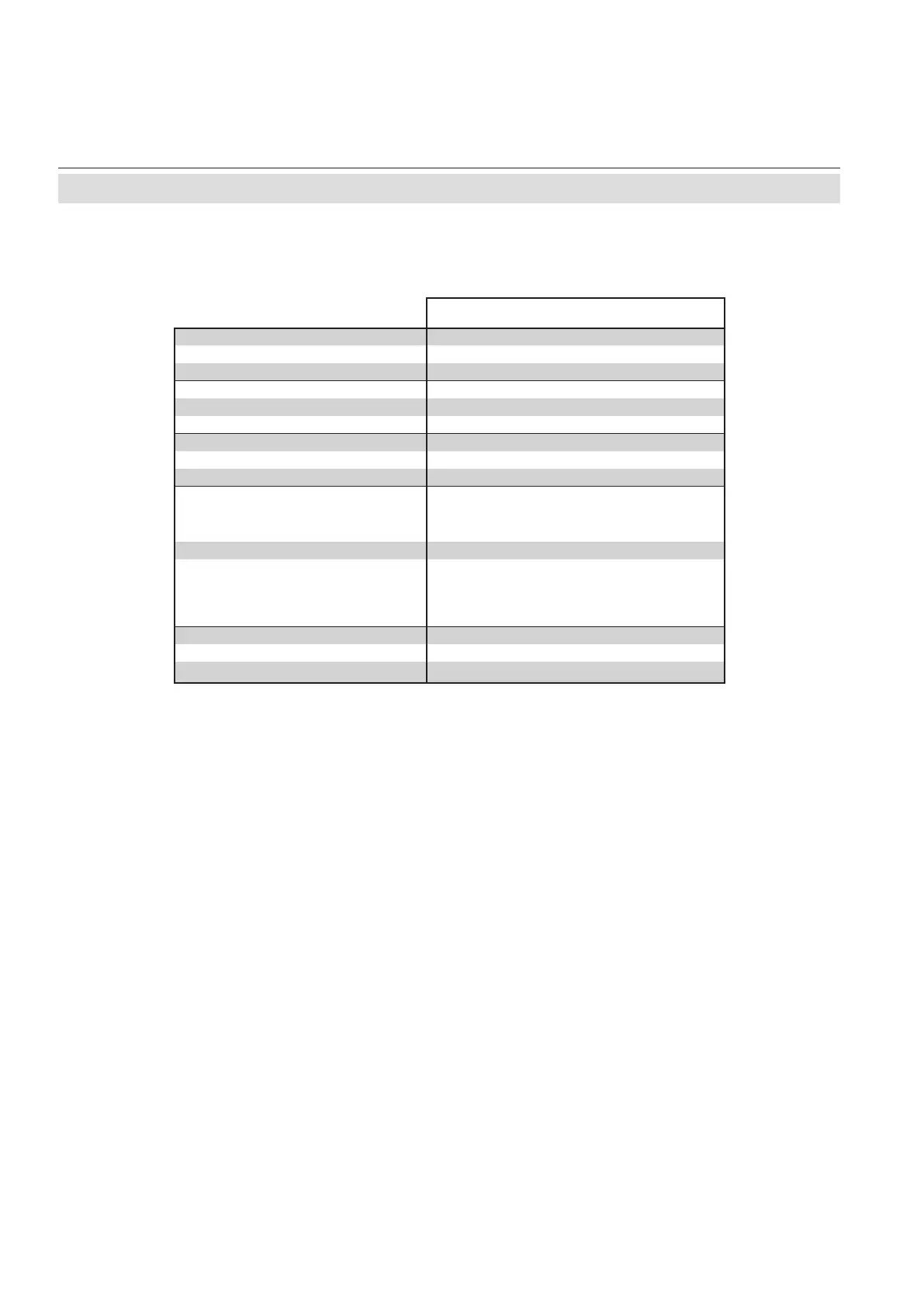

1.6 Measurement Specications

Special Performance Specications for Gas Purity Measurements (Suppressed Ranges)

Tab. 1-7: Special Performance Specications for Gas Purity Measurements (Suppressed Ranges)

1

Related to suppressed range (98–100 %)

2

Constant pressure and temperature

3

Daily zero and span calibration requested

4

Switching from absolute to suppressed range

requires purge time of > 240 s

5

Sample gas pressure sensor mandatory

6

Temperature variation: ≤ 10 K per hour

7

Related to permissible ambient temp. range

Note! 1 psi = 68.95 hPa

98–100 % CO

2

Detection limit (4 σ)

1 2

≤ 2 %

Linearity

1 2

≤

1 %

Zero-point drift

1 2 3

≤ 2 % per day

Span (sensitivity) drift

1 2 3

≤ 2 % per day

Repeatability

1 2

≤

2 %

Response time (t

90

)

4

≤ 30 s

Permissible gas ow dened by constant pressure at inlet

Permissible gas pressure 1300 hPa (4.4 psig) – 1700 hPa (10.1 psig)

Permissible gas pressure variation

±

70 hPa (1 psig)

Inuence of ambient pressure change

from 800 to 1100 hPa at constant tem-

perature with pressure compensation

1

5

≤ 2 %

Permissible ambient temperature +15 to +35 °C (59 to 95 °F)

Inuence of temperature

1 6

(at constant pressure)

– On zero point ≤ 0.5 % per 10 K

– On span (sensitivity)

7

≤ 2 %

Thermostat control 60 °C (140 °F)

Warm-up time approx. 50 minutes

Purge gas (N

2

) ow approx. 0.1–0.2 l/min

All performance data are veried during the manufacturing process for each unit by the following

tests:

• Linearization and sensitivity test

• Long term drift stability test

• Climate chamber test

• Cross interference test (if applicable)

Loading...

Loading...