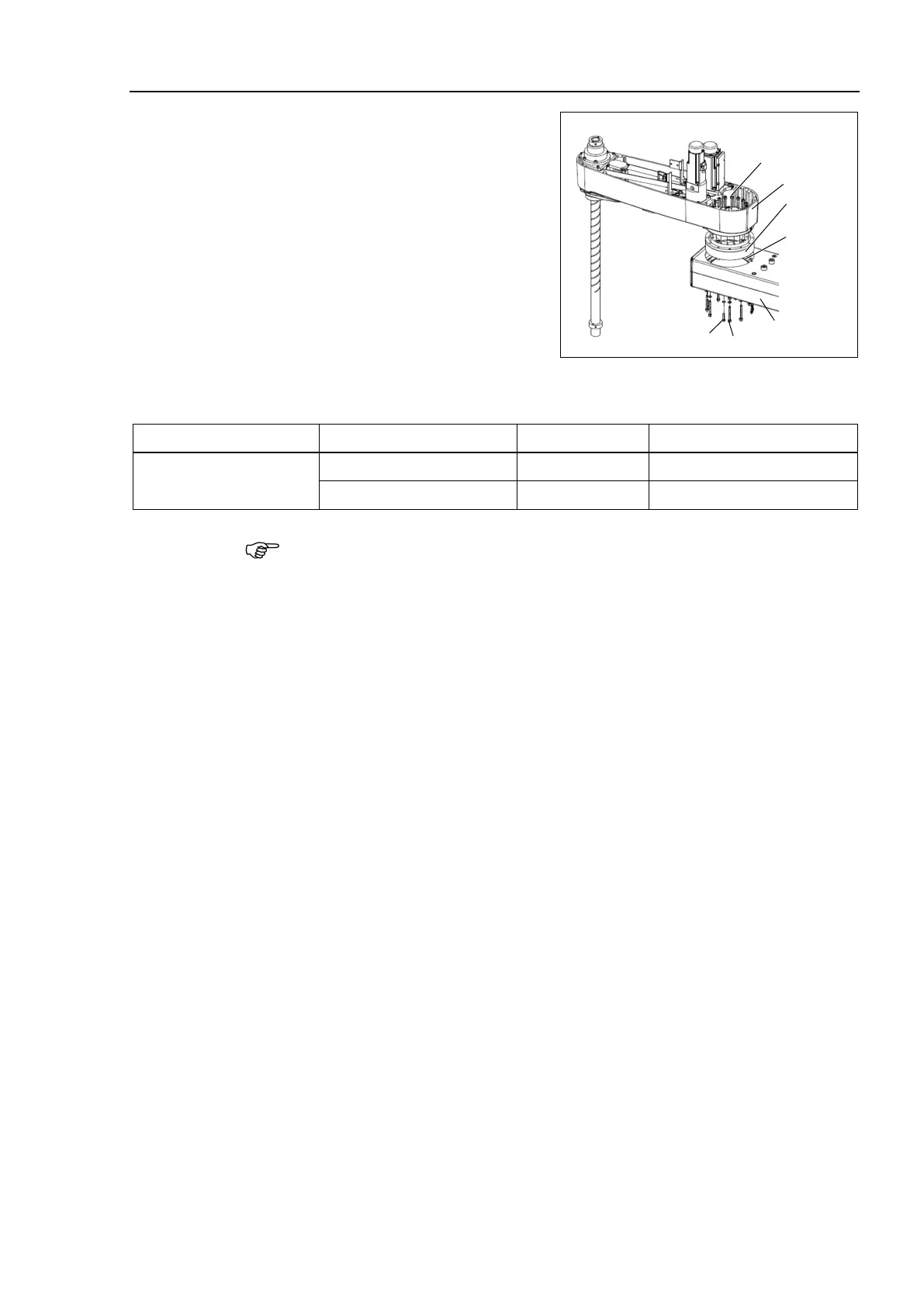

Maintenance 6. Arm #2

LS20 Rev.4 101

Set the O-ring removed in the removal

step (6) into the O-ring groove of the

Arm #1 and install the flexspline on

the Arm #1.

A: 16-M5×30

B: 8-M5×45+8-M5 plain washer

C: 4-M4×20+4-M4 plain washer

Loosely secure all bolts in a crisscross

pattern so that the bolts will be

secured evenly. Then, using a torque

wrench, tighten each bolt securely in a

crisscross pattern at the torque

specified in the table below.

Item Bolt type Qty. Tightening torque

Joint #2

reduction gear unit

M4 4 5.5 N⋅m (56.1 kgf⋅cm)

M5 8 10.0 N⋅m (102 kgf⋅cm)

Be careful not to apply too much force since it may damage the parts

Apply grease between the motor flange and waveform generator and next inside

the

Between the motor flange and waveform generator

Grease volume: 38 g (SK-1A)

Inside the flexspline

Grease volume: 90 g (SK-1A)

Set the attached O-ring into the O-ring groove of the circular spline.

Secure the Arm #2 on the circular spline.

Hexagon socket head cap bolts: 16-M5×30

Tightening torque : 10.0 N⋅m (102 kgf⋅cm)

and Joint #2 motor.

Follow the installation steps in

Maintenance: 6.1 Replacing Joint #2 Motor.

Loading...

Loading...