EVCO S.p.A.

c-pro 3 nano CHIL | Application manual ver. 1.0 | Code 144CP3NCHE104

page 61 of 90

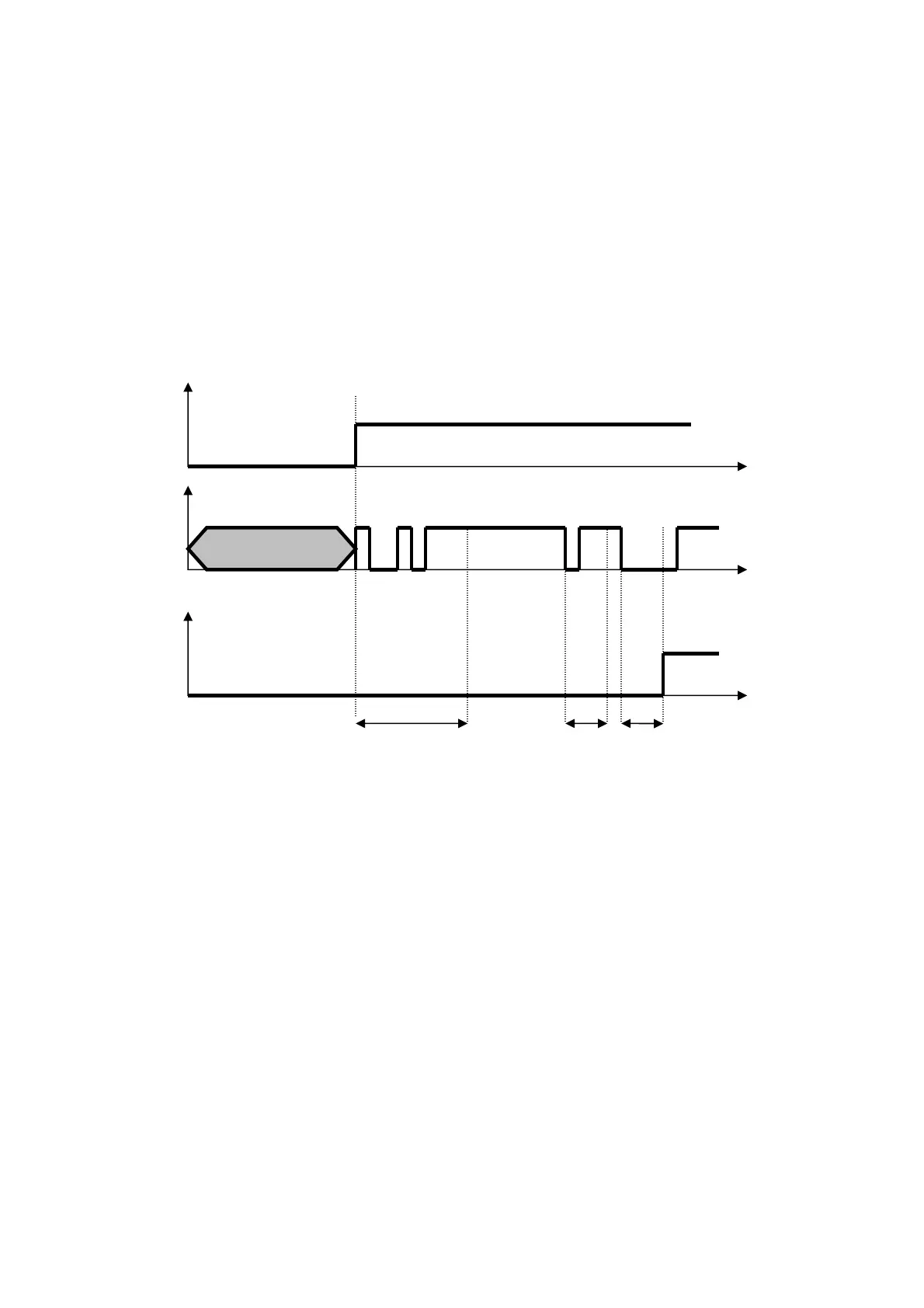

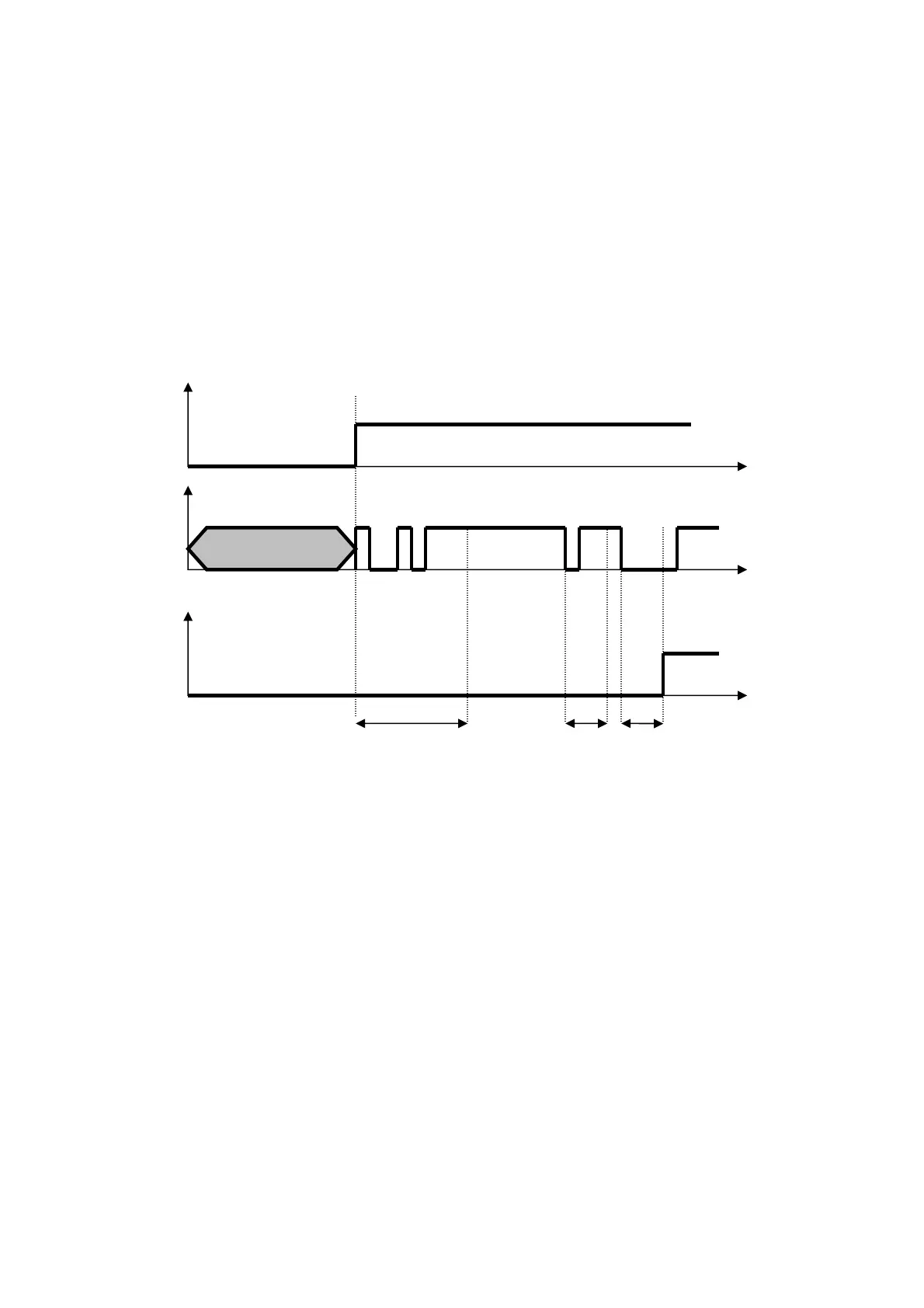

8.10.2 Flowmeter Management

The flowmeter is constantly monitored once the chiller has been started and the Flowmeter start-up delay PA01 has elapsed. If the

contact indicates a lack of flow, the flowmeter alarm goes off immediately. The compressors do not receive commands when there is a

flowmeter alarm.

During normal operation, the flowmeter is constantly monitored; if the contact reports lack of flow for a period exceeding the value of

the Flowmeter alarm bypass PA02 parameter, the associated alarm activates immediately and all the active compressors switch off.

If the alarm should persist for a time equal to the value of the Period of pump operation with low water level PP09 parameter, the pump

turns off, too, and the alarm becomes a manual reset The pump is therefore protected against operation without water. The pump

starts back up when the alarm is reset.

The flowmeter alarm is an alarm with manual reset, unless it exceeds a certain number of events in an hour (max. number of flow

alarms with automatic reset PA03), circumstance in which it becomes a manual reset.

8.11 Circulation Source Pump Management

On the WATER/WATER machines you can control one or two water circulation source pumps, which are set in parameter PG10. The

Pump operation PP21 parameter sets how the pump will work.

The controls for regulations, modes, flowmeter, and safeties of these devices are the same as those of the circulation pumps described

above.

8.12 Defrost Management

This procedure is activated only in winter operating mode (heat pump), and when at least one compressor is on. Defrost takes place by

acting on the coolant circuit inverter’s valve.

If for a time interval equal to the value of the Enable defrost delay Pd03 parameter, the evaporation pressure remains (even if not

constantly) below the Defrost start-up setpoint Pd01 threshold and at least one compressor is in function, the inverter’s valve is

reversed and the defrost cycle starts. During this stage, the compressors are forced to maximum power and the low pressure alarm is

bypassed.

Defrost stops for one of the following causes:

• when the pressure reaches the end of defrost setpoint Pd02;

• when the max. defrost duration Pd05 has elapsed;

• when the machine’s or the circuits’ alarms have activated;

• when the unit has been switched off.

At the end of the defrost cycle, the unit stays stopped for the entire duration of the Dripping period Pd06.

Unit

ON

OFF

Flow

ON

ON

Alarm

PA01 PA02 PA02

Loading...

Loading...