EVCO S.p.A.

c-pro 3 nano CHIL | Application manual ver. 1.0 | Code 144CP3NCHE104

page 73 of 90

Enablement of operation must come a few seconds before compressor start-up. The valve must be “prepared” open a percentage

adequate to the compressor being turned on.

8.20.2 PID Parameter Settings

The EVDRIVE03 has two sets of independent parameters to be used in the cooling (and defrost) and heating operating modes. The

controller must be able to choose the most appropriate set of parameters based on the operating mode. The set can be selected among

the two available or the parameters can be added directly (PV parameters can be obtained from the manufacturer menu).

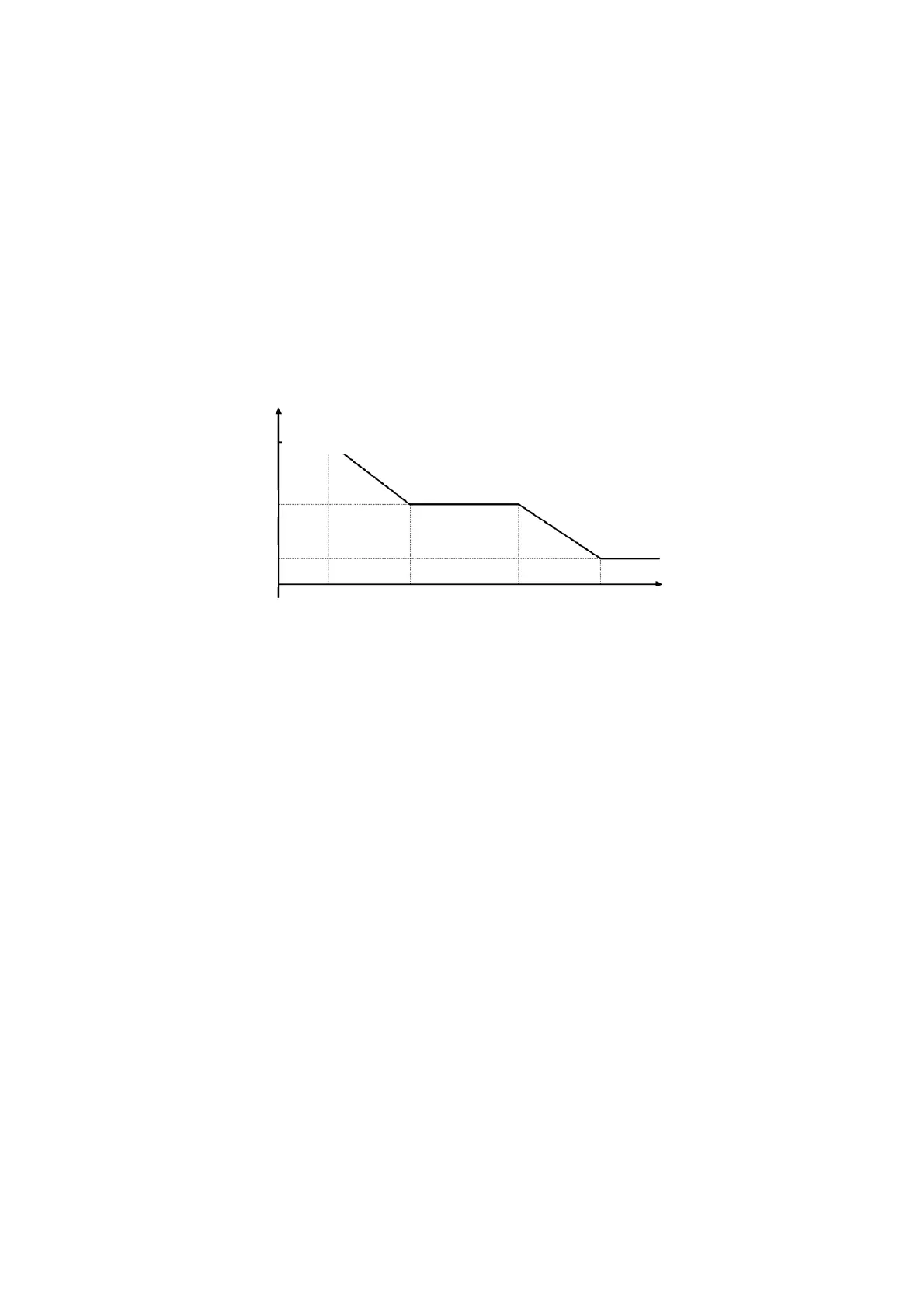

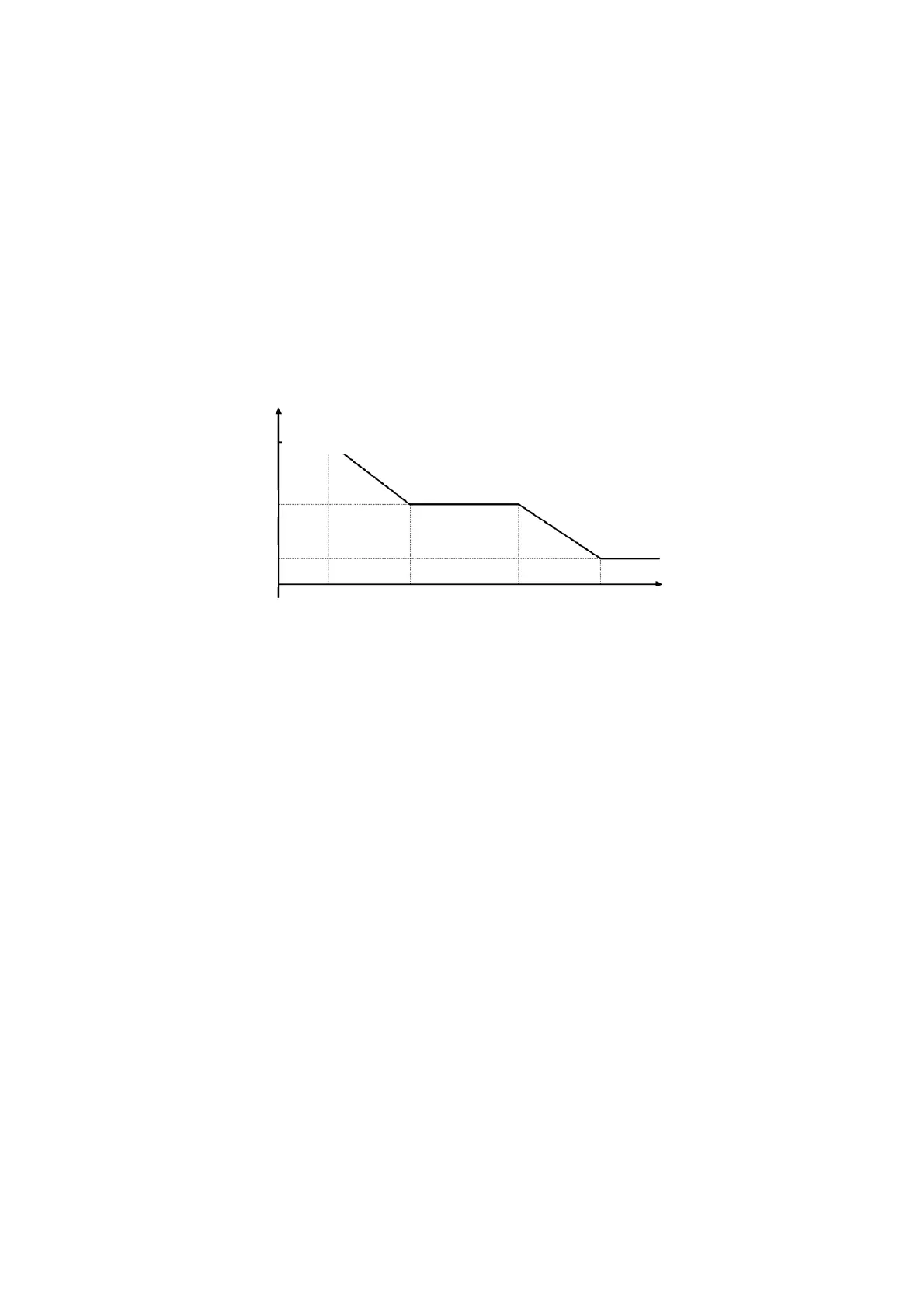

8.20.3 Modulation of the SH set

• If the DSH is below 10 K, there may be liquid returned to the compressor – to prevent this, it helps to increase the SH set.

• If the differential is higher than 20K, there is no risk of liquid return – given the “favourable” condition as far as safety of the

compressor you can lower the SH set to increase the system’s efficiency (reduction of the condensation pressure and increase of

the evaporation pressure).

These variations will have a minimum and maximum and will be parametrisable as shown in the figure.

This way the risk of liquid return to the compressor is limited and system efficiency increases based on the machine’s working

conditions.

8.20.4 CAN Configuration

To properly configure the valves of the two circuits, you have to set the CAN address and the transmission speed of each EVDRIVE03.

The valve of Circuit 1 must have CAN address=11, while the valve of Circuit 2 must have CAN address=12.

The transmission speed for CAN communication must be set based on parameter PH99.

8.21 Manual Operation

The programme lets you set the manual operation of compressors, fans, and pumps. In this condition, the devices are not involved in

the rotations or the calculations of thermal control, although they are still sensitive to any alarm.

Manual operation of the devices turns out to be useful when you have to perform run tests outside the machine to ascertain the

integrity and correct operation.

8.21.1 Compressors

Manual operation of compressors is guaranteed by parameter Enable compressor PM1x:

If set on Auto, it sets the normal behaviour of the device.

If set on Manu, it disables the compressor, reversing it to manual function.

A compressor in manual operation mode does not take part in the controls and it’s possible to force the number of steps that it can

provide, acting on the property Force compressor PM2x (in the MAin->MAnu menu).

In any event, as already stated, the compressor stays sensitive to any alarm and relative consequences.

SH

setpoint

SH setpoint

setpoint

Min (10K)

Min (20K)

Loading...

Loading...