IS620P User Manual Chapter 6 Troubleshooting

- 143 -

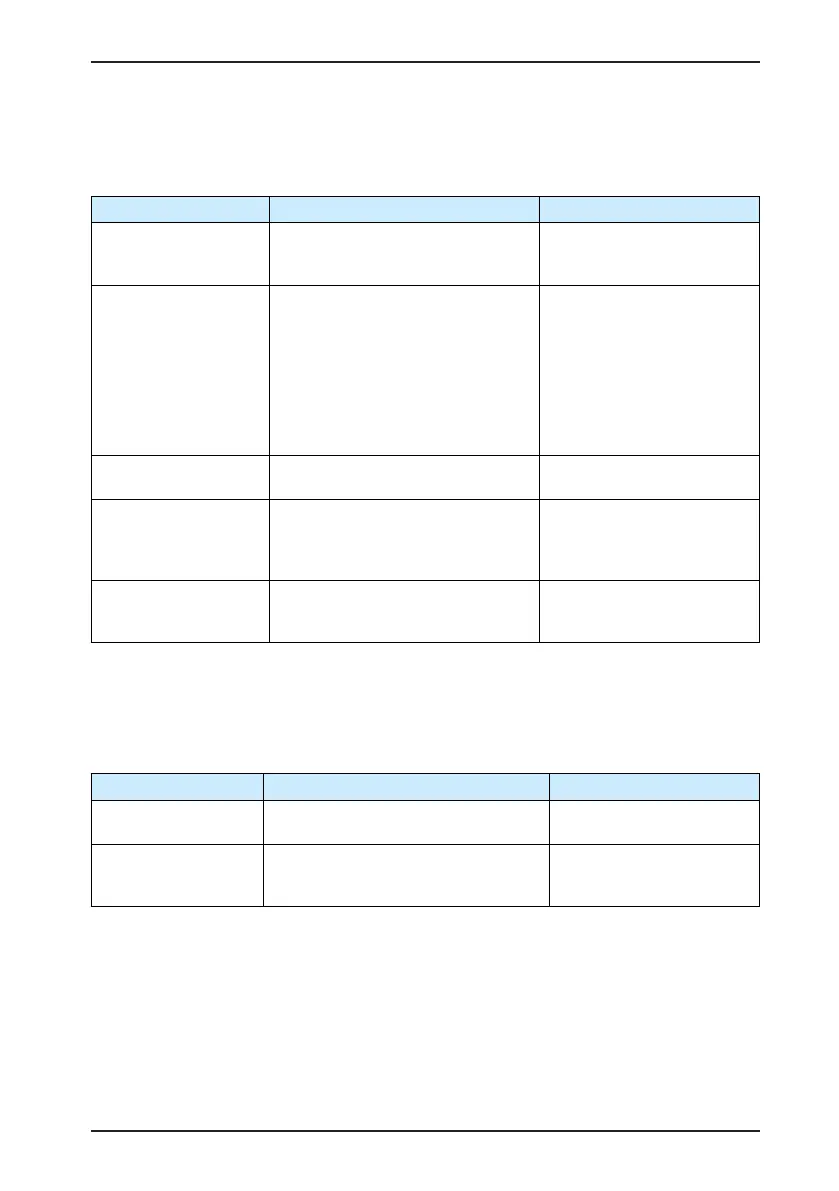

28. Er.650: Heatsink overheat

Cause:

•

The power module of the servo drive is higher than the overtemperature protection level.

Cause Conrming Method Corrective Action

1. The ambient

temperature is too high.

•

Measure the ambient temperature.

Improve the cooling conditions

to reduce the ambient

temperature.

2. The servo drive is

powered off and powered

on several times to reset

the overload fault.

•

View the fault records.

Set H0B-33 and view H0B-34, and

check whether the overload fault

(Er.610, Er.620, Er.630, Er.650,

Er.909, Er.920, Er.922) occurs.

Change the fault reset method.

After the overload occurs,

wait 30s and then perform

the reset operation. Increase

the capacity of the servo

drive and motor, increase the

acceleration/deceleration time,

and reduce the load.

3. The fan is damaged.

•

Observe whether the fan works

during running.

Replace the servo drive.

4. The installation

direction and clearance

of the servo drive are

improper.

•

Check whether the installation of the

servo drive is proper.

Install the servo drive according

to the mounting requirements.

5. The servo drive is

faulty.

•

Power off the servo drive, restart

it after 5 minutes. The fault still

remains.

Replace the servo drive.

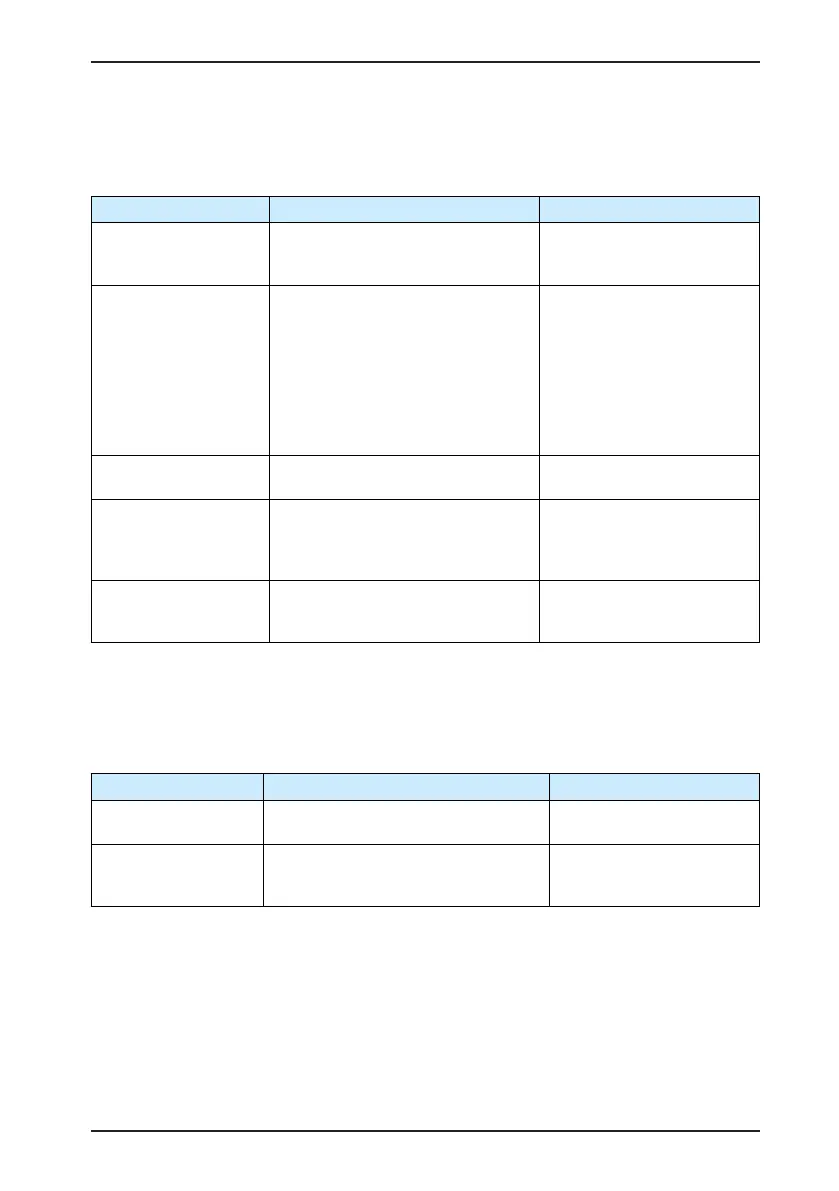

29. Er.740: Encoder interference

Cause:

•

The Z signal of the encoder suffers interference, resulting in too large change of

corresponding electrical angle of the Z signal.

Cause Conrming Method Possible Solution

1. The encoder wiring is

incorrect.

•

Check the encoder wiring.

Connect the encoder cable

correctly.

2. The encoder cable

becomes loose.

•

Check whether the on-site vibration is

too large, which loosens the encoder

cable and even damages the encoder.

Re-connect the encoder

cable securely.

Loading...

Loading...