6A–64 ENGINE MECHANICAL

3. Install the fan belts.

4. Adjust the fan belt tension.

Refer to “Fan Belt Inspection” in this manual.

Disassembly

Ring Gear

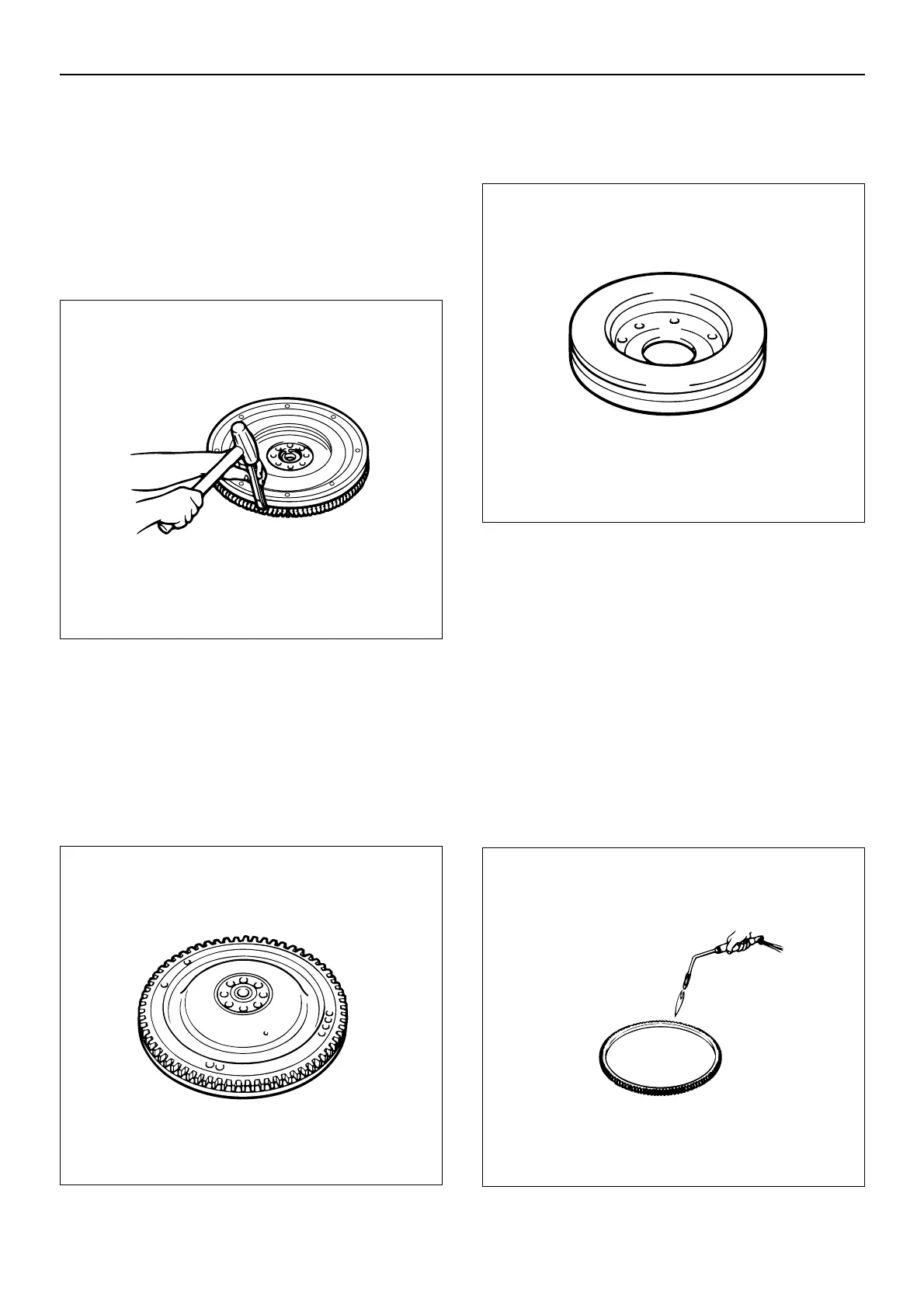

1. Strike around the edges of the ring gear with a

hammer and brass bar to remove it.

Damper

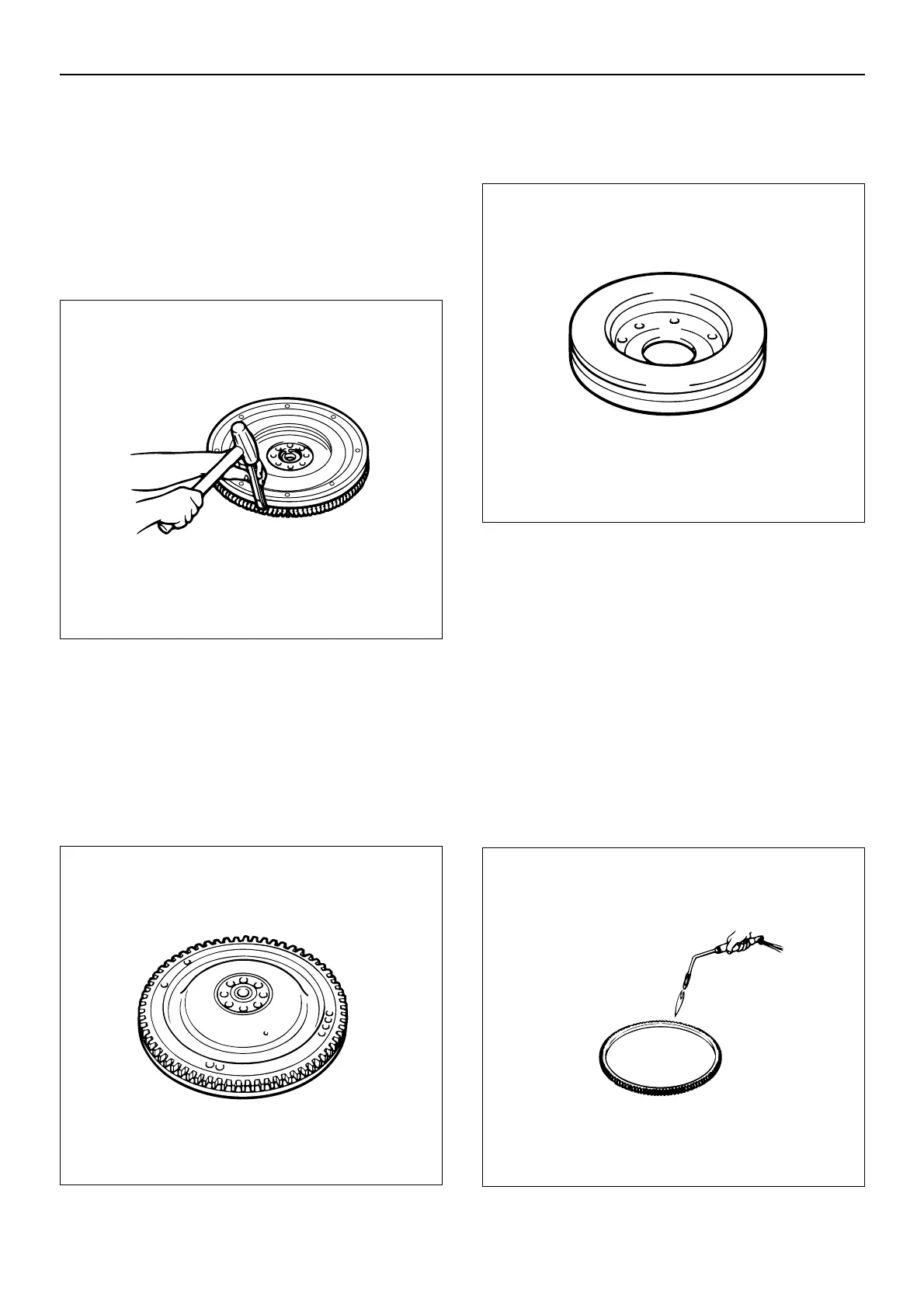

1. Remove the damper from the crankshaft pulley.

Inspection and Repair

1. Inspect the ring gear for damage or excessive wear.

If the ring gear teeth are broken or excessively worn

the ring gear must be replaced.

2. Inspect the crankshaft damper for cracking or

separation. If any abnormality on the crankshaft

damper is found, inspect the crankshaft and the

flywheel fixing bolts.

Reassembly

Ring Gear

1. Install the ring gear to the flywheel.

1. Heat the ring gear evenly with a gas burner to

invite thermal expansion.

Do not allow the temperature of the gas burner to

exceed 200°C (390°F).

WARNING: Take care not to burn yourself on the

heated ring gear.

2. Install the ring gear when it is sufficiently heated.

The ring gear must be installed with the chamfer

facing outside.

015EY00075

014EY00116

014EY00117

015LX103

Loading...

Loading...