6A–68 ENGINE MECHANICAL

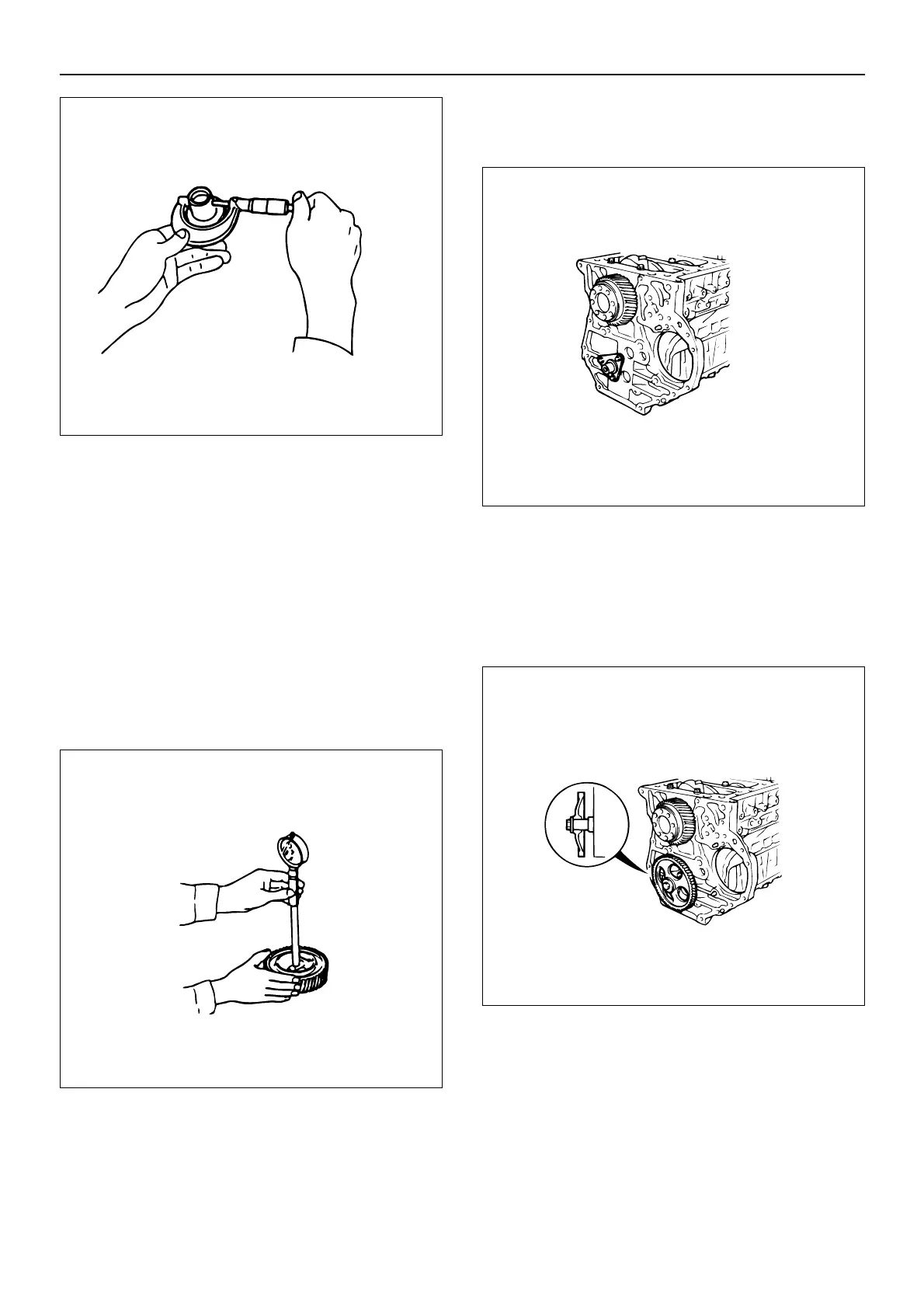

2. Use an inside dial indicator or an inside micrometer

to measure the idler gear inside diameter.

If the clearance between the idler gear shaft outside

diameter and the idler gear inside diameter exceeds

the limit, the idler gear and/or shaft must be

replaced.

Idler gear shaft and Idler gear clearance

Shaft A

Standard: 0.025 – 0.075 mm (0.00098 – 0.00295 in)

Limit: 0.2 mm (0.008 in)

Shaft B and C

Standard: 0.020 – 0.062 mm (0.0008 – 0.0024 in)

Limit: 0.2 mm (0.008 in)

Installation

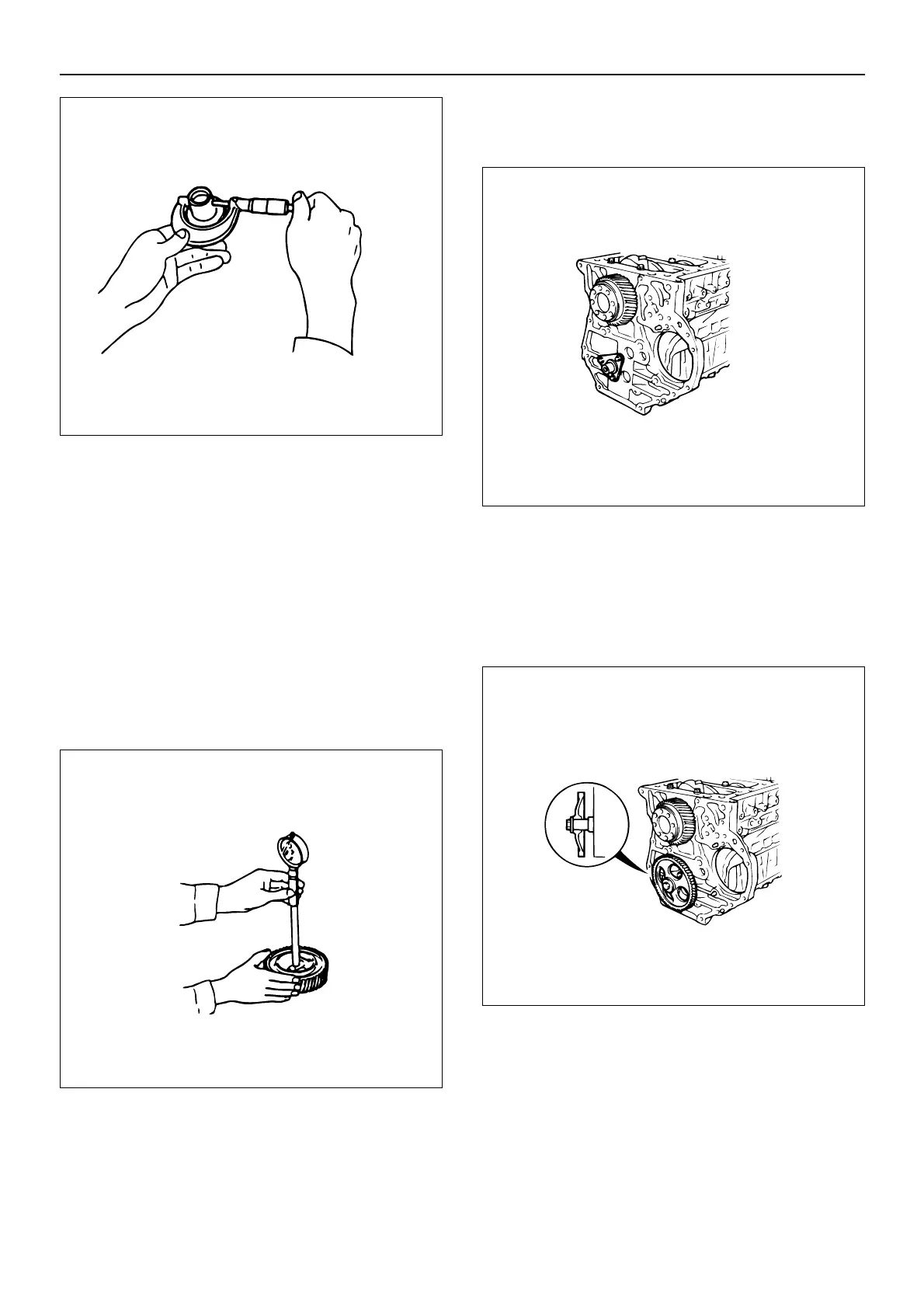

1. Install the idler gear B shaft.

1. Install the idler gear B shaft to the cylinder body.

The idler gear shaft oil port must be facing the

cylinder head.

2. Tighten the idler gear shaft bolts to the specified

torque.

Torque: 31 N·m (3.2 kgm/23 lbft)

2. Install the idler gear B to the idle gear shaft.

1. Apply engine oil to the idler gear B inside and

thrust areas.

2. Install the idler gear to the idler gear shaft.

3. Tighten the idler gear bolts to the specified torque.

Torque: 95 N·m (9.7 kgm/70 lbft)

3. Install the oil pump to the cylinder block.

1. Carefully wipe any foreign material from the

cylinder body rear surface.

2. Apply engine oil to the cylinder body inside

bushing.

014EY00175

014EY00054

014EY00055

014EY00176

Loading...

Loading...