ENGINE LUBRICATION 6G–9

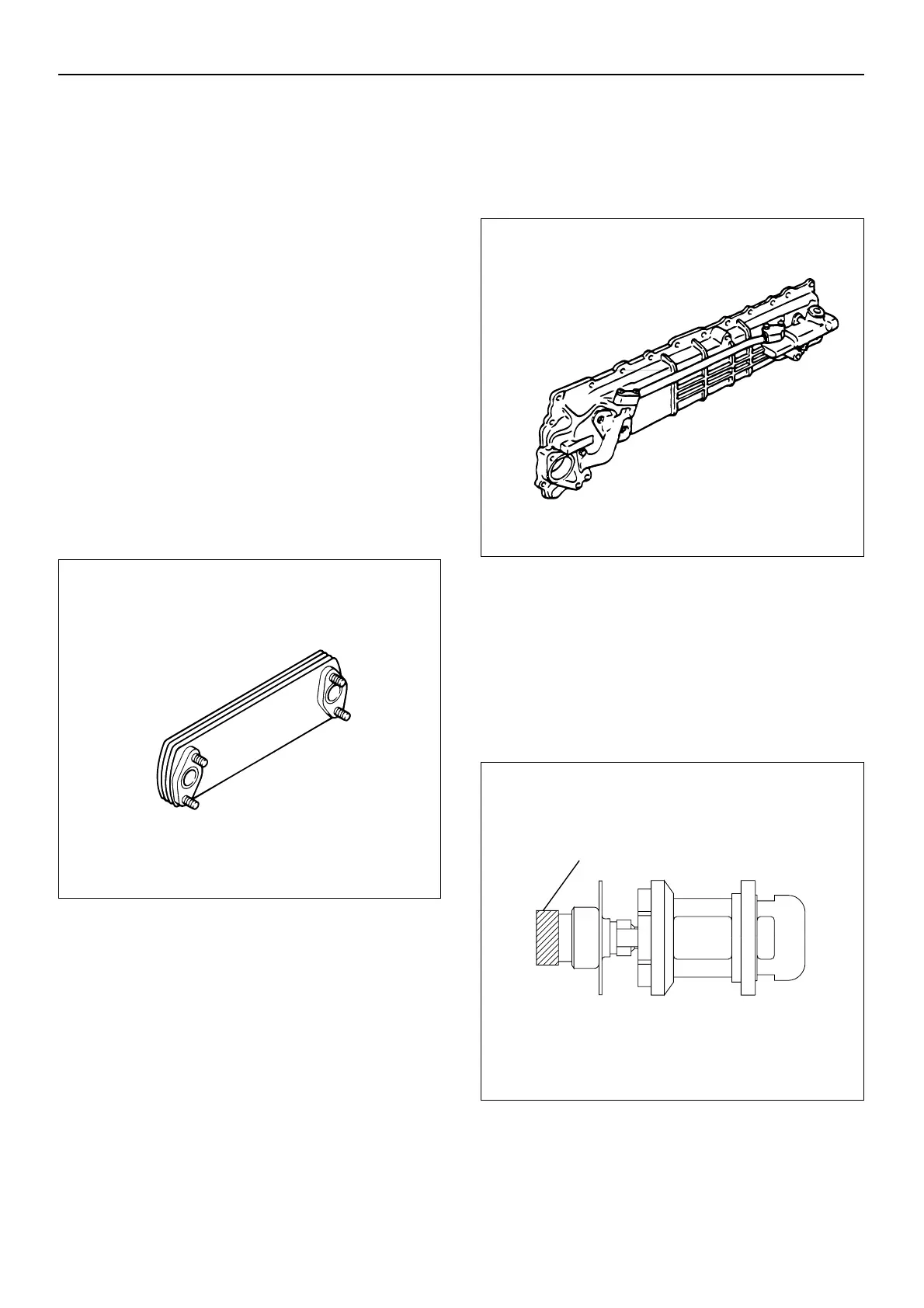

1. Loosen the fixing nuts to remove the element.

Discard the gaskets.

2. Remove the bypass pipe.

3. Remove the oil thermostat.

4. Clean the inside of the oil cooler element.

1. Use a funnel to pour cleaning solution into the oil

cooler element.

Add cleaning solution until it overflows.

2. Allow the oil cooler element to stand for ten hours

(with the cleaning solution inside).

3. Pour off approximately 1/3 of the cleaning

solution from the element.

4. Apply compressed air at 200kPa (28 psi) to the

element through the oil port. Continue to apply

compressed air until all cleaning solution has been

forced from the element.

WARNING: Compressed air can cause personal

injury, when used protective for cleaning. Wear

safety glasses and protective clothing.

NOTE : As long as the oil cooler element is not damaged

or excessively dirty, it may be cleaned repeatedly at

periodic intervals.

Inspection and Repair

1. Use the dye penetrant detector procedure to inspect

the element for cracking.

2. Use the dye penetrant detector procedure to inspect

the oil cooler cover for cracking.

Reassembly

1. Install the bypass pipe with new gasket to the body.

2. Install the oil thermostat with the rubber cap to the

body.

3. Install the plug with new gasket to the body and

tighten to the specified torque.

Torque : 20 N·m (2.0 kgm/14 lbft)

050EY00015

050EY00058

Loading...

Loading...