ENGINE MECHANICAL 6A–109

1. Remove the lower crankcase.

• Loosen the fixing bolts to disassemble the lower

crankcase.

• Place the crankcase on a flat piece of wool.

2. Remove the oil jet.

Loosen the bolt to remove the oil jet.

NOTE: Take care not to bend or damage the oil jet.

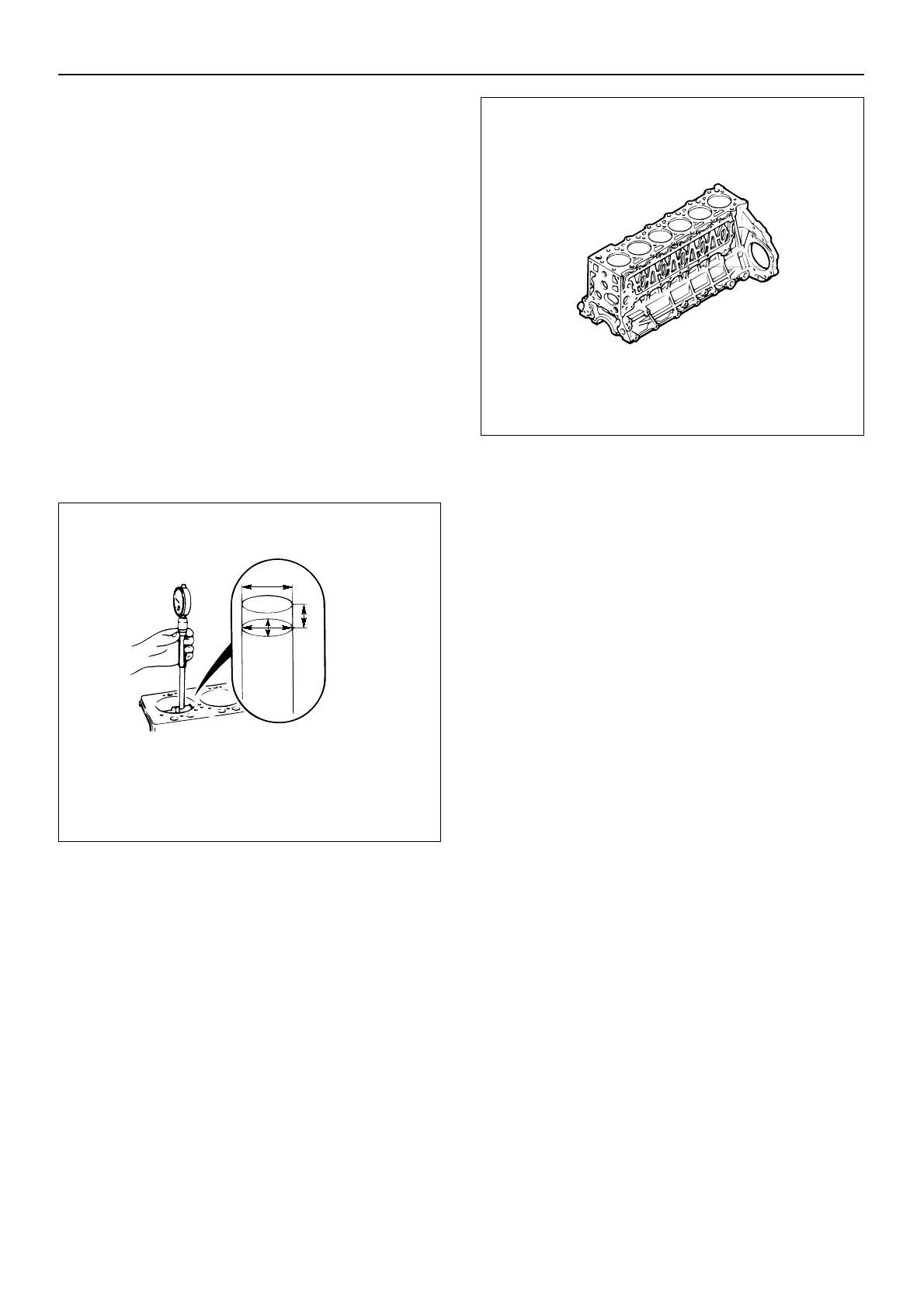

3. Remove the cylinder liner.

• Use a scraper to remove carbon deposits.

• Use a cylinder bore dial indicator to measure the

cylinder bore in the thrust and axial direction of the

crankshaft before removing the cylinder liner.

Measuring point: 20 – 25 mm (0.79 – 1.0 in.)

If the measured value exceeds the specified limit,

the cylinder liner must be replaced.

Cylinder liner bore

Limit: 115.2 mm (4.5354 in.)

NOTE: If the inside of the cylinder liner is scored or

scratched, the cylinder liner must be replaced.

The cylinder liner is loose fit type.

The cylinder liner can be removed with hands.

If the cylinder liner removal is difficult, press it from

the crankcase side.

Visually inspect the cylinder block for damage.

Inspection and Repair

Make the necessary adjustment, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

Cylinder Block Flatness

• Remove the cylinder liners.

• Inspect the cylinder block for cracks and other

damage. Check the oil and water holes for

clogging.

If possible, use dye pendant flow detector.

• Use a straight edge (1) and a feeler gauge (2) to

measure cylinder block upper face warpage (4

sides and 2 diagonals as shown in the illustration).

Upper face warpage

Limit: 0.2 mm (0.008 in.)

012EY00036

012EY00043

Loading...

Loading...