6A–102 ENGINE MECHANICAL

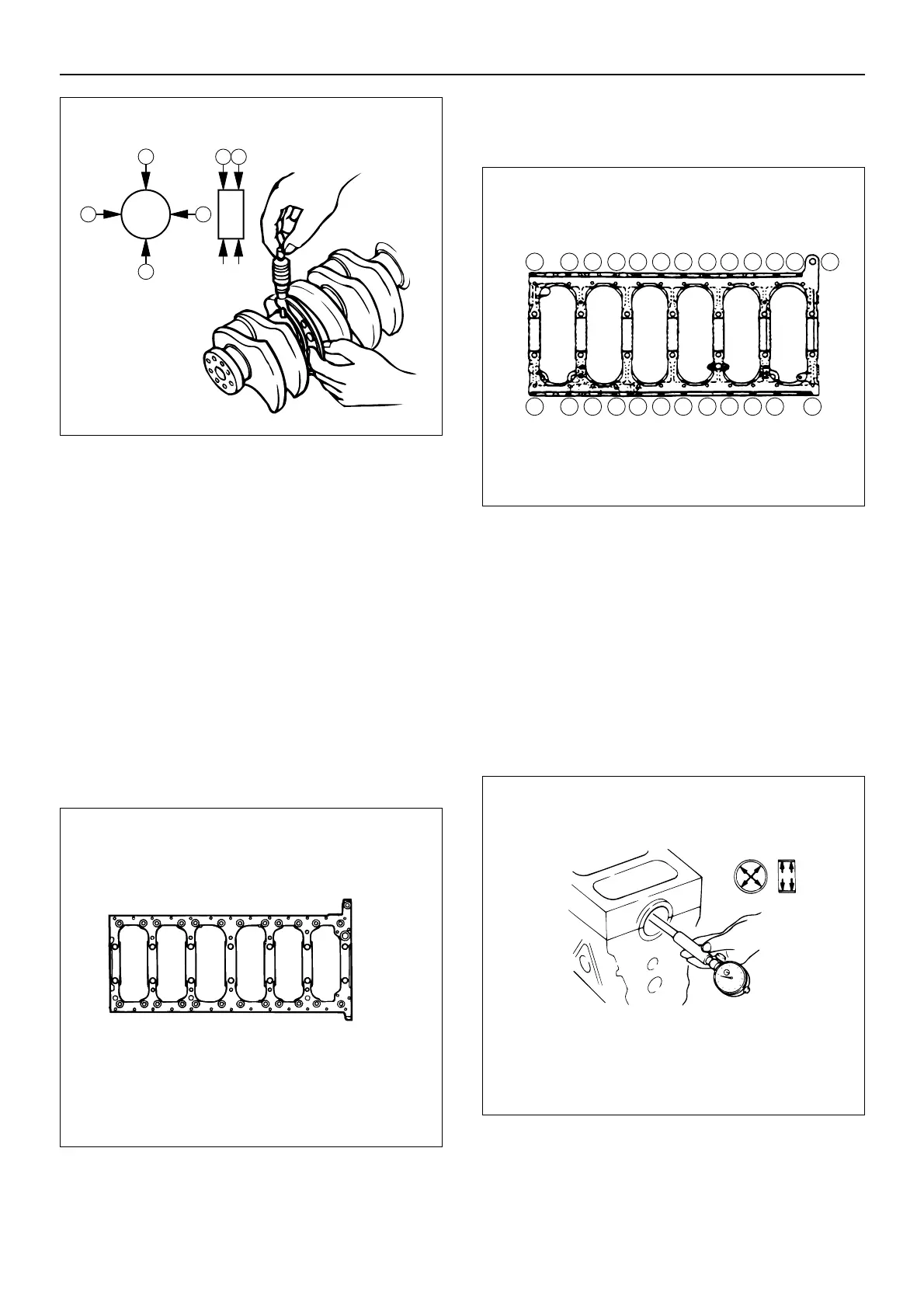

Crankshaft Bearing Inside Diameter

1. Clean the cylinder body and lower crankcase

bearing fitting surfaces. Clean the bearing inside and

outside surfaces.

2. Install the lower crankcase with the bearings to the

cylinder body.

3. Apply molybdenum disulfide grease to the lower

crankcase bolt threads and setting faces.

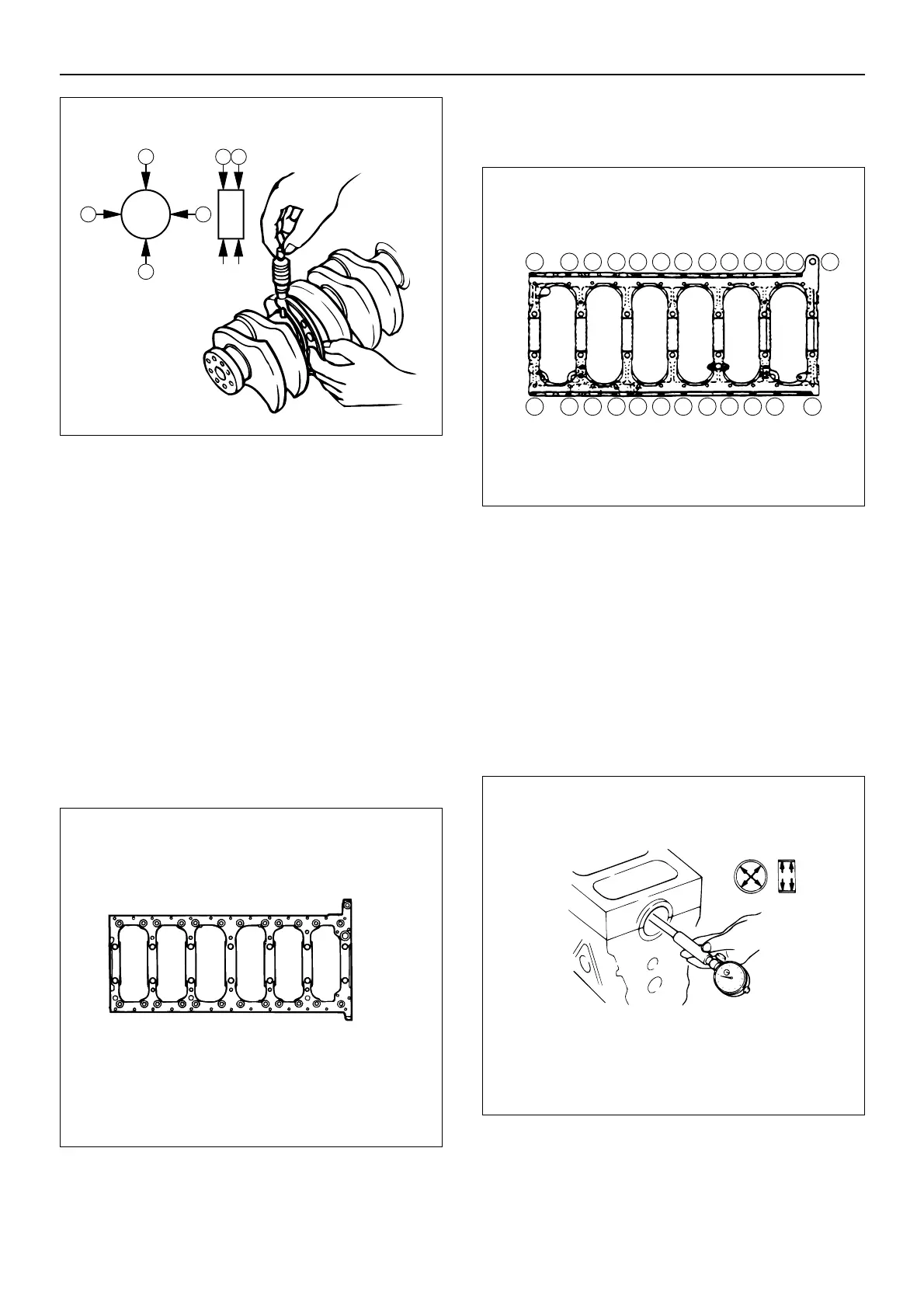

4. Tighten the lower crankcase M14 bolts in three steps

using the angular tightening method.

Torque:

1st step : 98 N·m (10 kgm/72 lbft)

2nd step: 132 N·m (13.5 kgm/98 lbft)

3rd step: 30 – 60 deg.

NOTE: Cylinder body lower crankcase M14 bolts can be

reused 6 times before replacement.

5. Tighten the lower crankcase M10 bolts to the

specified torque.

Torque: 37 N·m (3.8 kgm/27 lbft)

6. Use an inside dial indicator to measure the

crankshaft bearing inside diameter.

Crankshaft Journal and Bearing Clearance

If the clearance between the measured bearing inside

diameter and the crankshaft journal diameter exceeds

the specified limit, the crankshaft must be replaced.

Crankshaft journal and Bearing clearance

Standard:

No.4 journal: 0.093 – 0.124 mm (0.00366 – 0.00488 in)

Others: 0.063 – 0.094 mm (0.00248 – 0.00370 in)

Limit: 0.14 mm (0.0055 in)

Loading...

Loading...