ENGINE MECHANICAL 6A–101

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

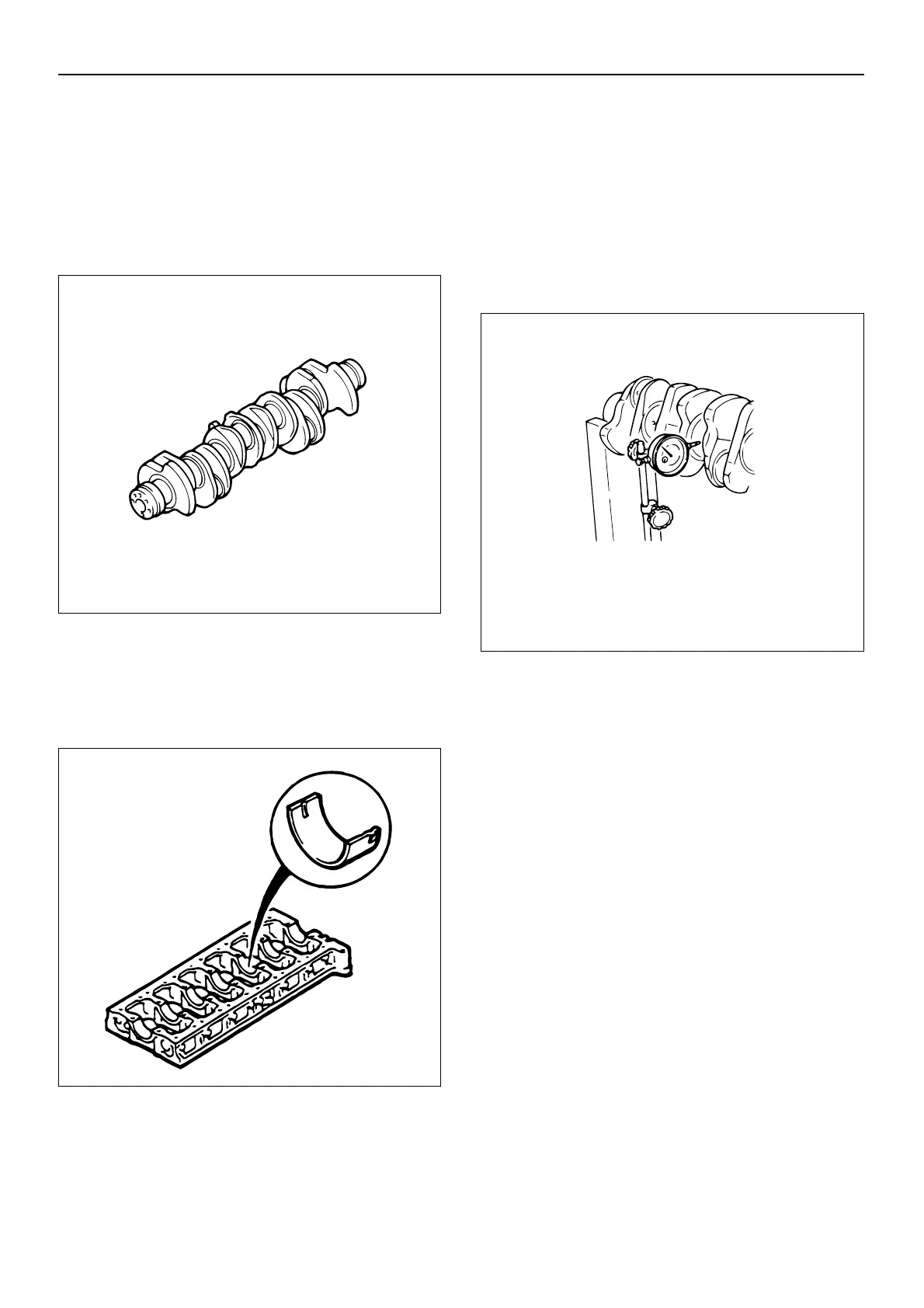

Crankshaft

Inspect the surface of the crankshaft journals and

crankpins for excessive wear and damage.

Inspect the oil ports for obstructions.

Bearing Spread

Check the bearing spread.

Finger pressure should be sufficient to fit the bearing

into position.

If the bearing fits loosely, it must be replaced.

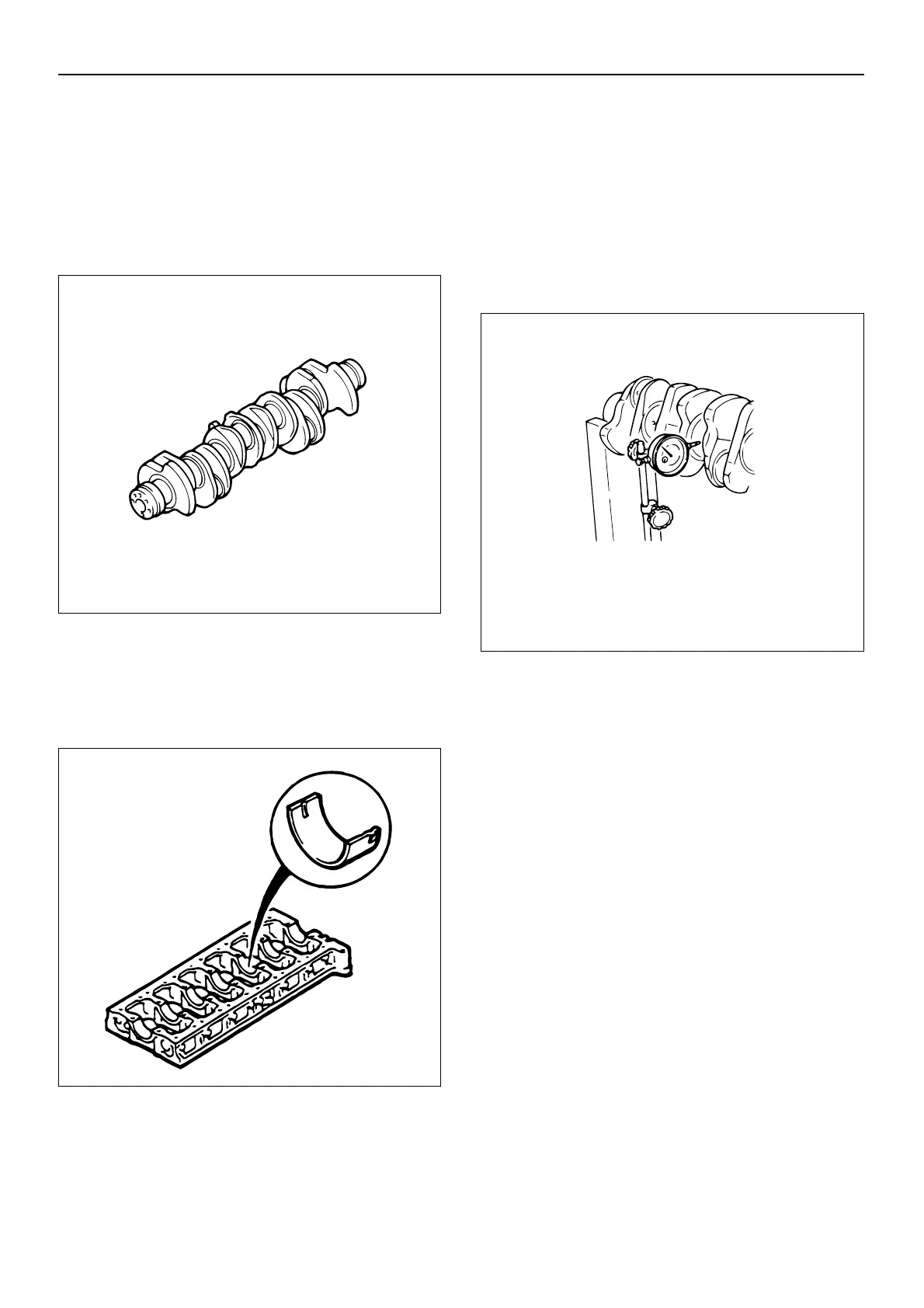

Crankshaft Run-Out

1. Set a dial indicator to the center of the No.4

crankshaft journal.

2. Gently turn the crankshaft in the normal direction of

engine rotation.

Read the dial indicator as you turn the crankshaft.

If the measured value exceeds the specified limit, the

crankshaft must be replaced.

Standard: 0.06 mm (0.0024 in) or less

Limit: 0.45 mm (0.018 in)

Crankshaft Journal and Crankpin Diameter

1. Use a micrometer to measure the crankshaft journal

diameter across points (1) – (1) and

(2) – (2).

2. Use the micrometer to measure the crankshaft

journal diameter at the two points ((3) and (4)).

3. Repeat Steps 1 and 2 to measure the crankshaft pin

diameter.

Crankshaft journal diameter

Standard:

No. 4 journal: 81.875 – 81.895 mm

(3.2234 – 3.2242 in)

Others: 81.905 – 81.925 mm (3.2246 – 3.2254 in)

Crankshaft pin diameter

Standard: 65.902 – 65.922 mm (2.5946 – 2.5953 in)

Crankshaft journal and crankpin uneven wear

Limit: 0.05 mm (0.0020 in)

014EY00118

015EY00189

014EY00120

Loading...

Loading...