ENGINE MECHANICAL 6A–91

The grade mark is stamped on the top of the piston

installed at the factory, but service part pistons do not

have any grade (single grade).

Piston outside diameter

Standard: 114.894 – 114.909 mm

(4.5233 – 4.5240 in.)

Piston and Liner bore clearance

Standard: 0.122 – 0156 mm (0.0048 – 0.0061 in.)

If the piston and liner clearance exceeds the standard

value, the piston and/or liner must be replaced.

CAUTION: Cylinder liner kit clearances are preset.

However, the cylinder liner installation procedure

may result in slight decreases in cylinder liner

clearances. Always measure the cylinder liner

clearance after installation to be sure that its is

correct.

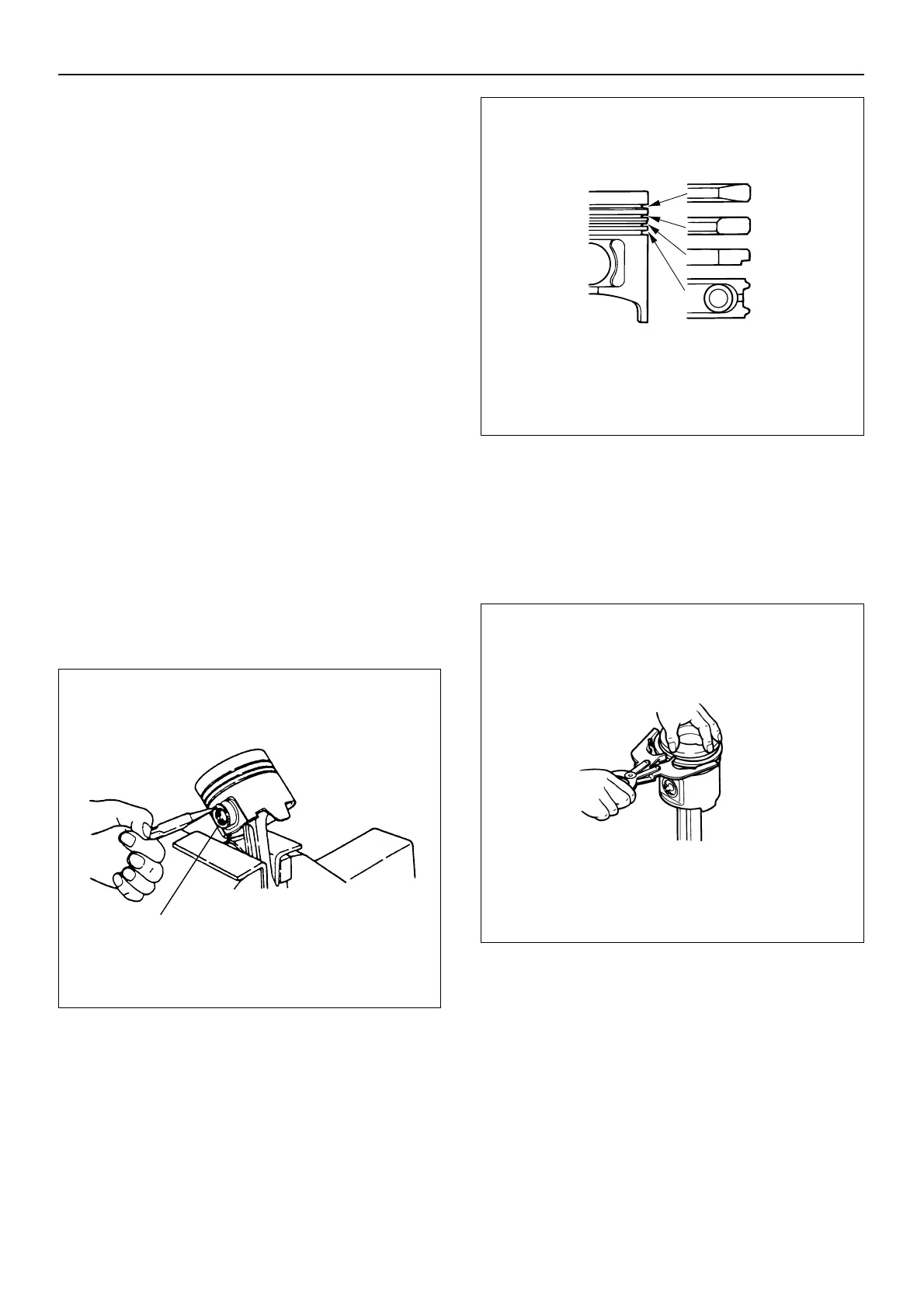

Reassembly

1. Install the snap ring (1).

Use a pair of snap ring pliers to reassemble the snap

ring to the piston.

2. Install the connecting rod and piston pin.

• Clamp the connecting rod in a vise.

Take care not to damage the connecting rod.

• Install the piston so that the piston head front mark

and the connecting rod front mark face the

opposite direction.

• Apply engine oil to the piston pin.

• Insert the piston pin to the connecting rod through

the piston pin hole in the piston.

• Install the snap ring.

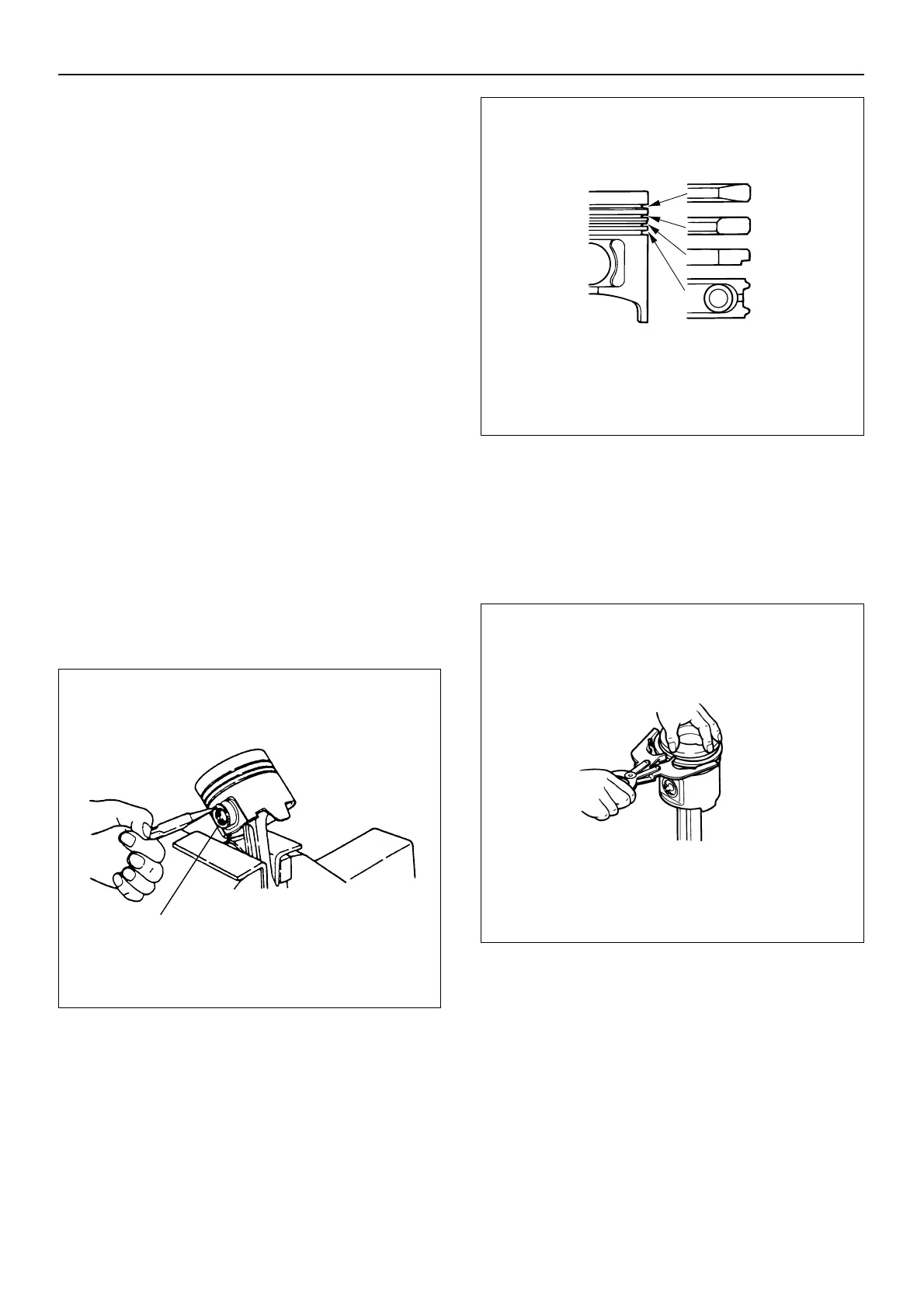

3. Install the piston ring.

• Apply engine oil to the piston rings.

• Install the compression rings with the stamped side

facing up.

• Use the piston ring setting tool 1-85221-029-0 to

reassemble the four piston rings according to the

top mark on the piston ring.

The oil ring does not have a top mark.

NOTE: Insert the expander coil into the oil ring groove so

that there is no gap on either side of the expander coil

before installing the oil ring.

• Check that the piston rings rotate smoothly in the

piston ring grooves.

4. Install the connecting rod bearing.

Carefully wipe any oil or other foreign material from

the connecting rod bearing back faces and the

bearing fitting surfaces.

015EY00183

Loading...

Loading...