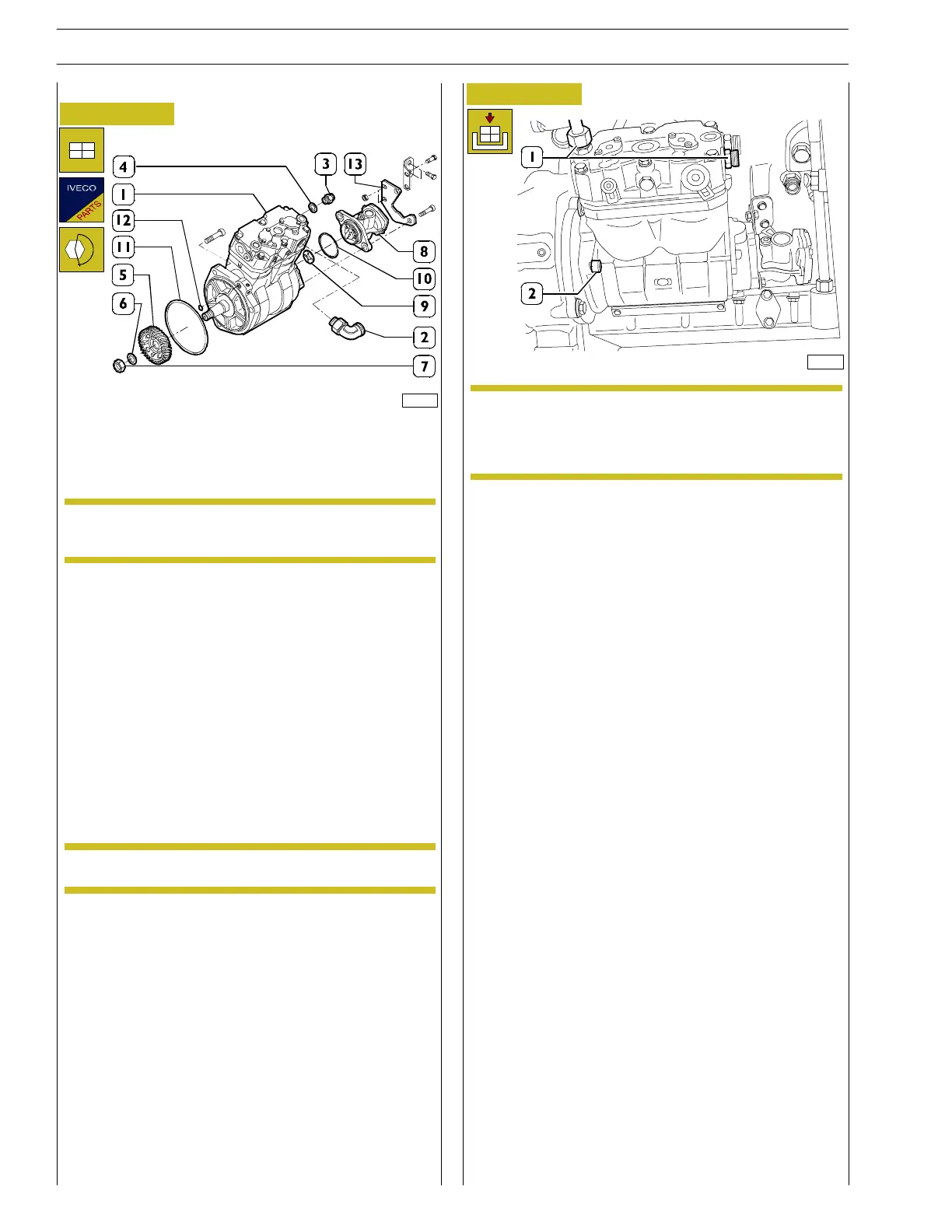

Figure 77

- On the bench, fit the previously removed fittings onto

the compressor (1): suction (2) and compression (3)

fittings: thread M26 = 100 Nm.

Change the gasket (4) at the fittin g mounted on the

compression port.

- Insert the gear (5), flat washer (6) and screw down the

nut (7), tightening to a torque of from 160 ÷ 180 Nm.

- Fit the low-pressure pump (8), inserting the universal

joint (9) and O-rin g (10).

Change the gaskets (10), (11) and (12).

Should compressor have been dismou nted join tly

with spacer, tigh ten (M12x1.75) screws securing it

to gears box at 42 ÷ 51 Nm tightening torque.

- Put compressor into its seat by tighten i ng (M12x1.75) at

74÷90NmNmtorque.

- Secure bracket (13, Figure 77) to engine bloc k.

- During assembly, check th at the coupling drive (9) an d

the teeth on the front of the secondary circuit cooling

pump gear show n o signs of wear or cracks. Change any

damaged parts.

- Fit support bracket (13) and tighten the s crews securing

the low—pressure pump support to the air compressor

to the prescribed to rque: 42÷51 Nm.

For DRAGON applications

89697

NOTE

NOTE

89698

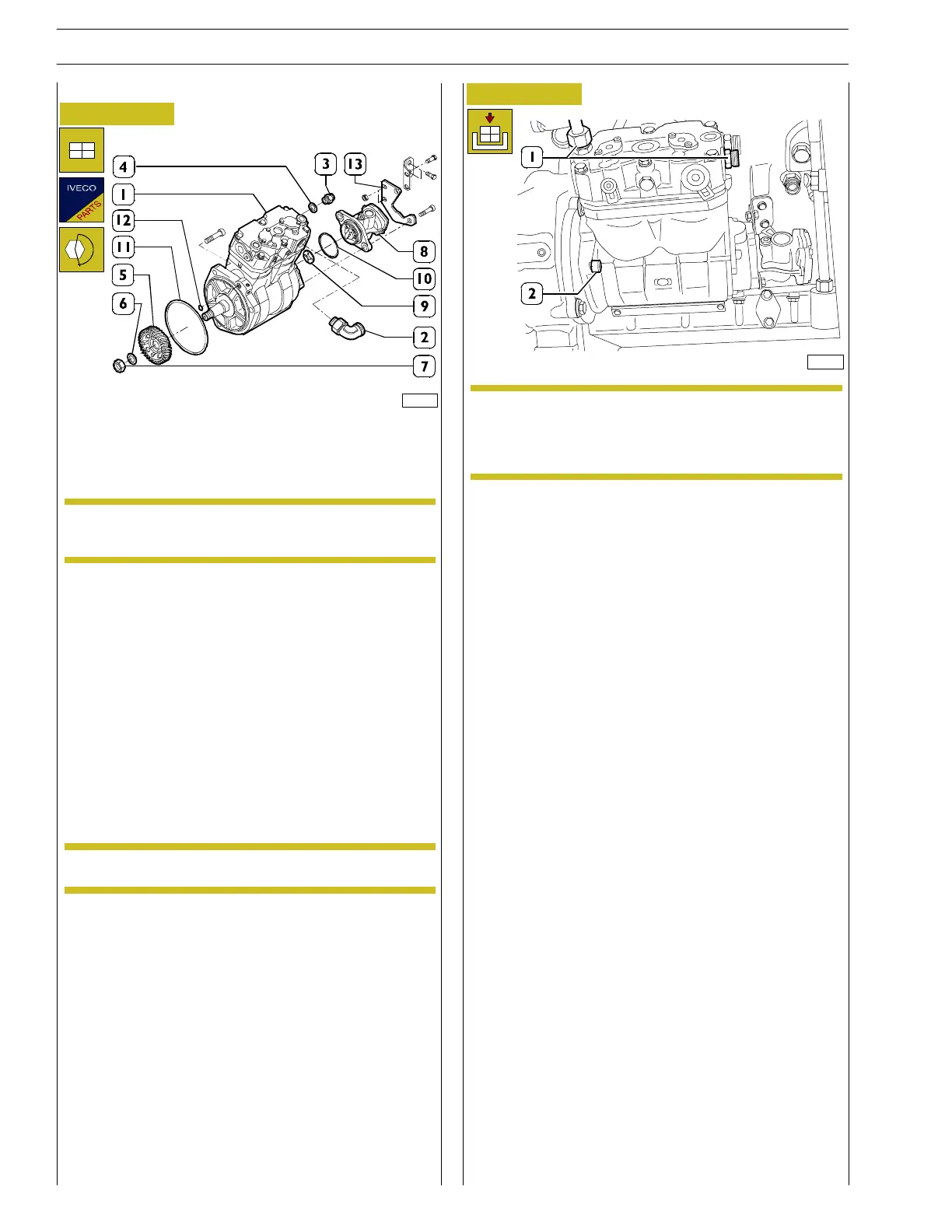

Figure 78

NOTE

36

SECTION 3 - INDUSTRIAL APPLICATION

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...