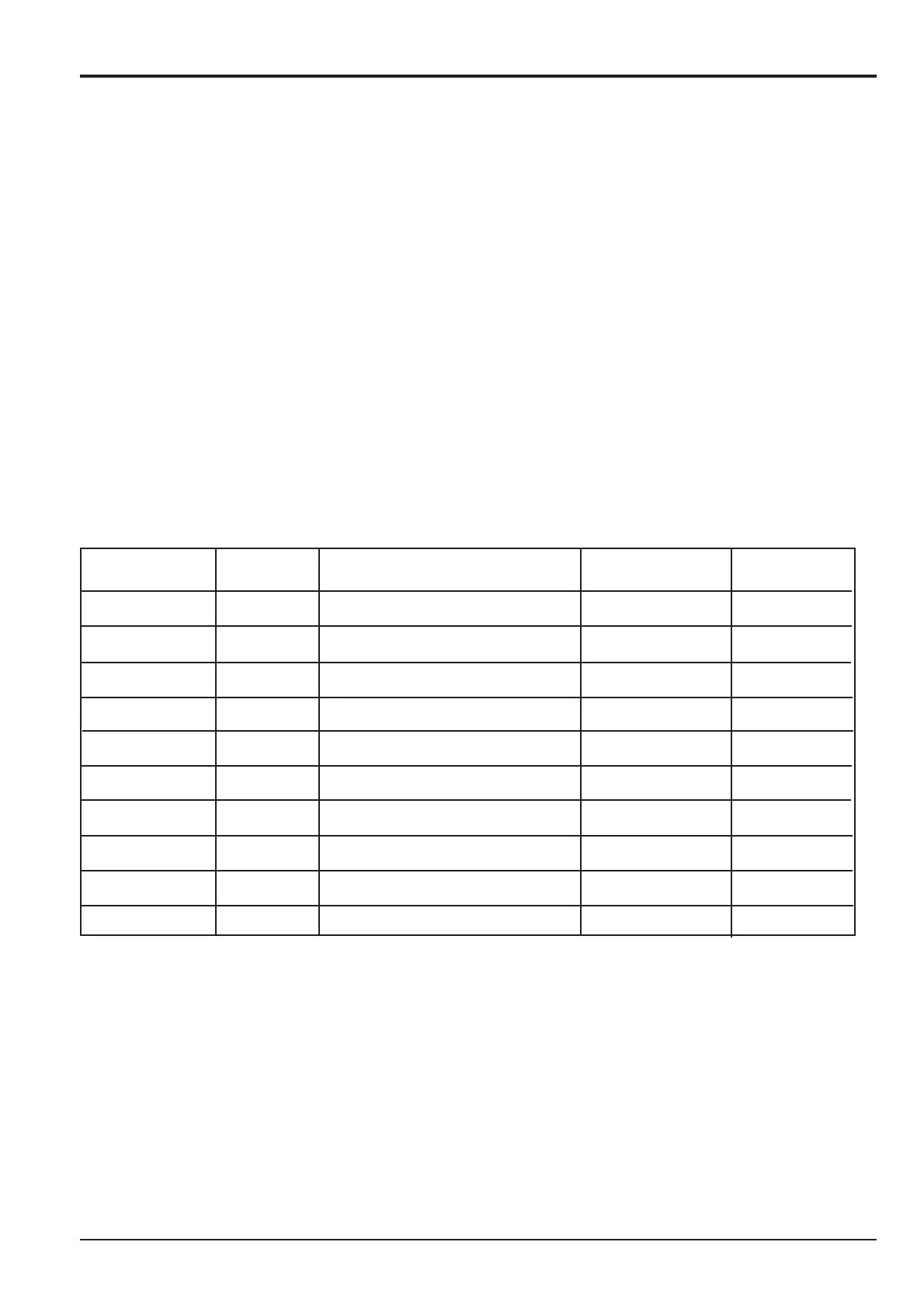

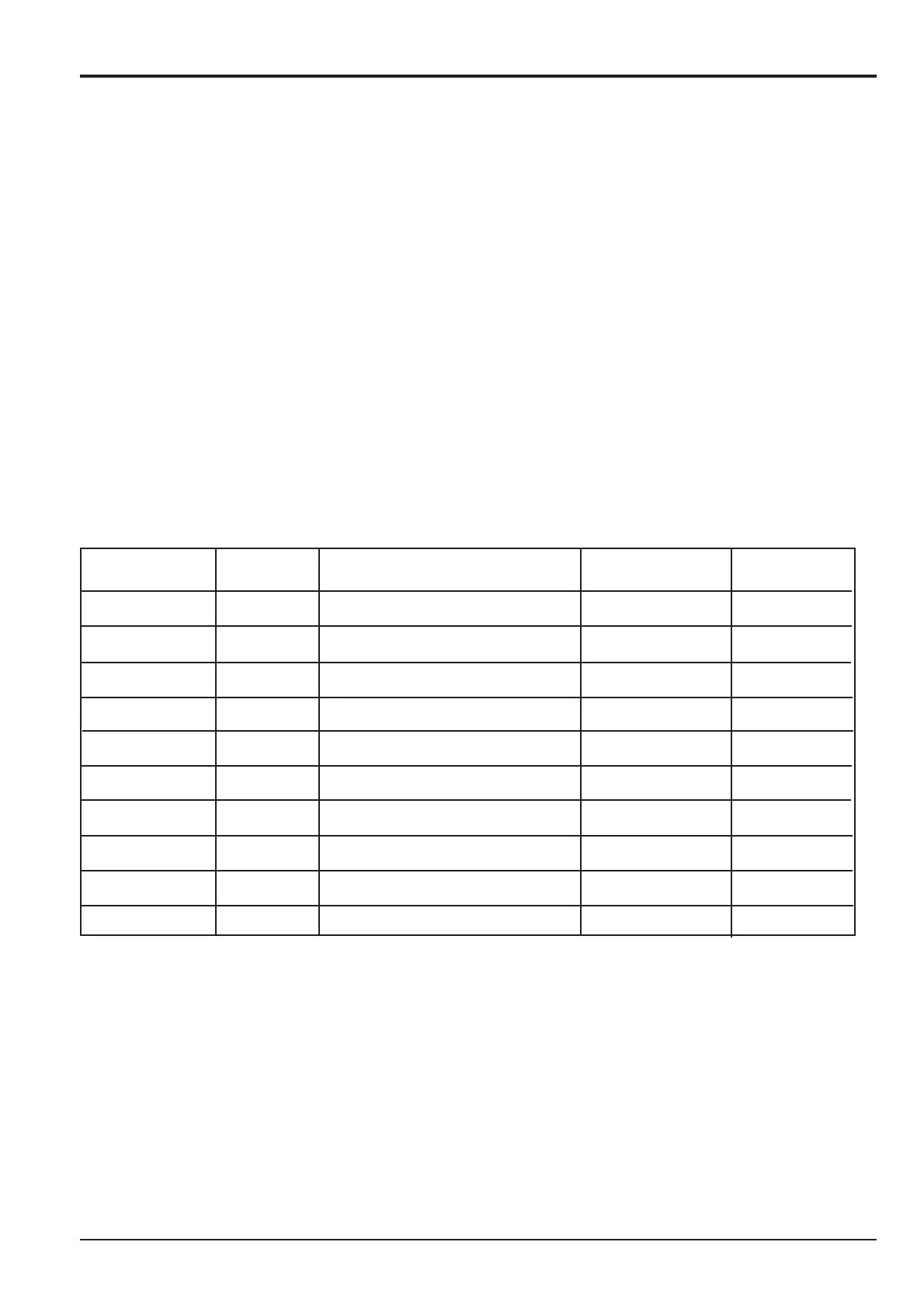

4 - 3

Pressure Measurement Measurement

Part Name bar (lb/in

2

) Method Port

Main Relief 279 - 284 bar (4046 - 4119 lb/in

2

) Dipper Relief G1(G2)

Boom Port Relief Up 304 - 314 bar (4409 - 4554 lb/in

2

) Boom Up Relief G2

Down 255 - 265 bar (3698 - 3843 lb/in

2

) Boom down Relief G2

Bucket Port Relief Out/In 304 - 314 bar (4409 - 4554 lb/in

2

) Bucket Relief G2

Dipper Port Relief Out/In 304 - 314 bar (4409 - 4554 lb/in

2

) Dipper Relief G1

Swing Port Relief Left/Right 201 - 209 bar (2915 - 3031 lb/in

2

) Swing Relief G1

Blade Main Relief 221- 231 bar (3205 - 3350 lb/in

2

) Blade Up G4

Blade Port Relief Up/Down 250 - 260 bar (3626 - 3771 lb/in

2

) Blade Relief G4

Pilot Relief 34 - 44 bar (493 - 638 lb/in

2

) Lever Neutral G3

Accumulator 15 ± 5 bar (217 ± 72.5 lb/in

2

)G3

Section E Hydraulics

9803/6020

Section E

4 - 3

Issue 1

Pressure Testing

Pressure Testing - General

Confirmation of the oil Temperature

Confirm the oil temperature is between 45° - 55° C using a

thermometer. If the temperature is low use the following

warm-up procedure.

Warming-up Procedure

1 Turn the Throttle Control to mid-range and make sure the

Work Mode Selection Switch is set to S.

2 Press the One Touch Idle Switch.

3 Run the engine until the Coolant Temperature gauge

reads within the normal (green) range.

4 Set the Servo Isolator Switch to ON to enable the

hydraulic servo controls to be operated.

5 Operate the bucket control slowly until it reaches one end

of its travel and leave it there for 30 seconds.

6 Operate the bucket control slowly to the other end of its

travel and leave it there for 30 seconds.

7 Repeat steps 5 and 6 for 10 minutes to warm up the

hydraulic circuit.

8 Now operate the excavating controls three to five times in

each direction to distribute warm hydraulic oil around the

system.

Loading...

Loading...