1 - 1

Section 3 Routine Maintenance

9803/6020

Section 3

1 - 1

Issue 1

Fluids and Lubricants

Note: New engines DO NOT require a running-in period. The engine should be used in a normal work cycle immediately;

glazing of the piston cylinder bores, resulting in excessive oil consumption, could occur if the engine is gently run-in. Under

no circumstances should the engine be allowed to idle for extended periods (e.g. warming-up without load).

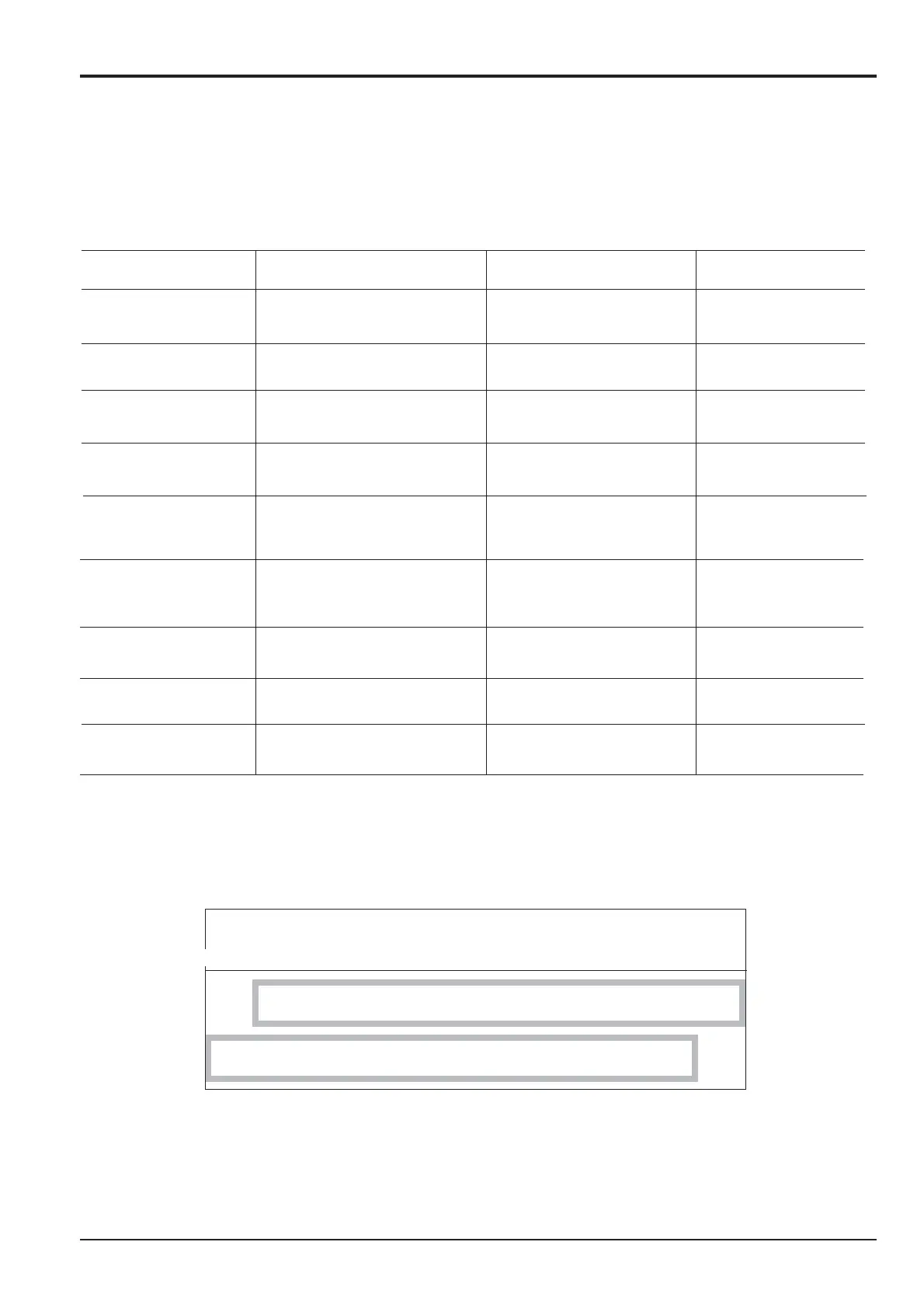

Item Fluid/Lubricant International Specification Capacity

ENGINE See separate chart - 6.8 litres

(1.49 UK gal)

SLEW GEARBOX JCB HP Grease Lithium based, No. 2 0.2 kg

consistency (0.44 lb)

TRACK GEARBOXES JCB Gear Oil HD90 API-GL-5, MIL-L-2105C 2 x 1.7 litres

(0.37 UK gal)

TRACK ROLLERS AND

IDLER WHEEL Engine Oil (see separate chart) - -

HYDRAULIC SYSTEM JCB Special Hydraulic Vickers 35VQ25/V104C: 92 litres

Fluid HP46 Sundstrand, Denison and (20.26 UK gal)

FZG Approval Tests

SLEW RING

- BEARINGS JCB HP Grease Lithium based, No. 2 -

- GEAR TEETH JCB HP Grease consistency 3.2 kg (7.14 lb)

ALL OTHER GREASE Lithium based, No. 2

POINTS JCB HP Grease consistency

COOLING SYSTEM See Coolant Mixtures ASTM D3306-74 10.1 litres

(2.22 UK gal)

FUEL TANK See Fuel System, ASTM D975-66T 140 litres

Types of Fuel Nos 1D, 2D (30.8 UK gal)

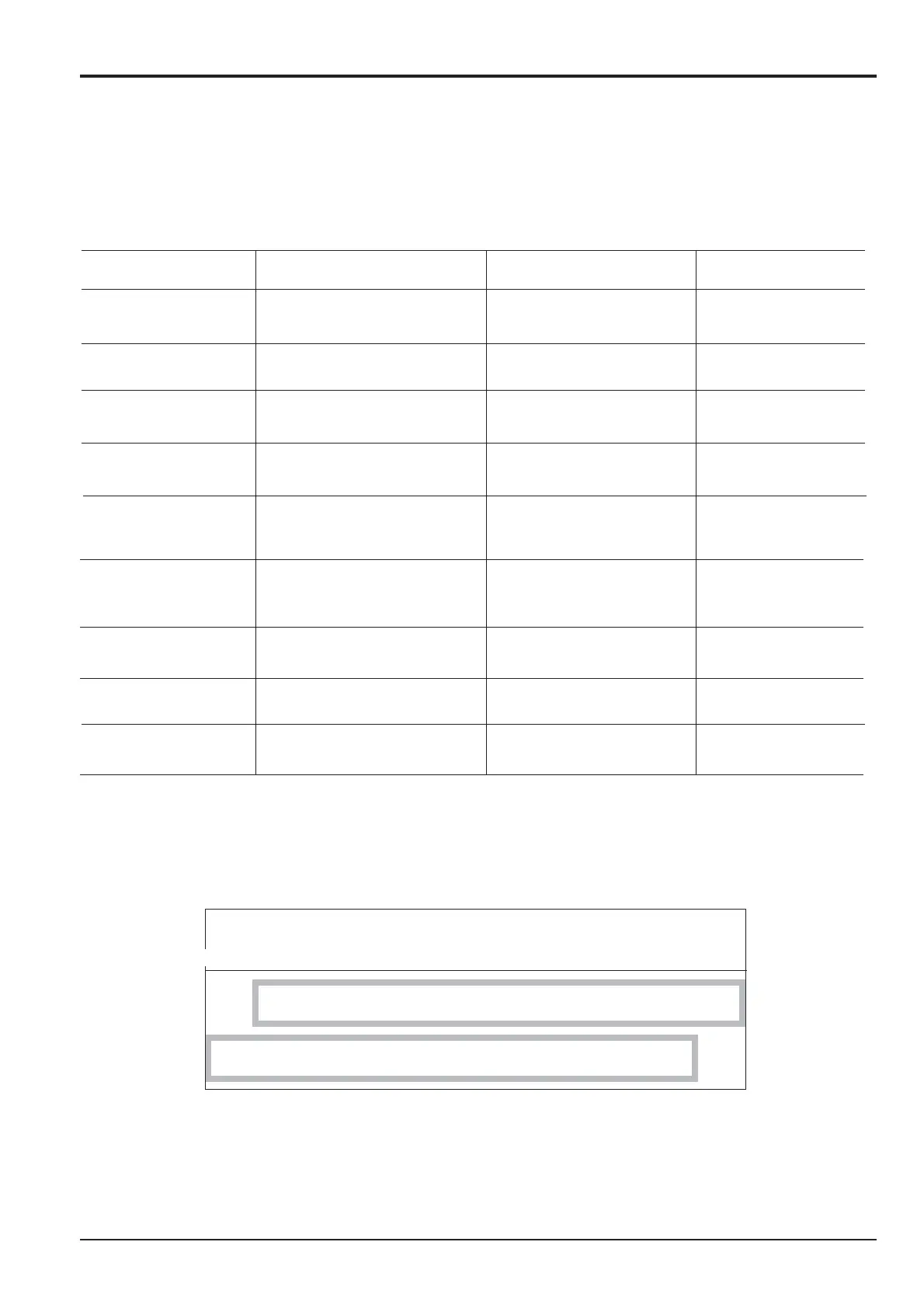

Engine Lubrication Chart

JCB SUPER 15W/40 MULTIGRADE ENGINE OIL

API CF4/SG MIL L-2104F

JCB SUPER UNIVERSAL AGRICULTURAL (10W/30)

API CE/SF MIL L-2104D

Use according to ambient temperature (°C)

-20 -10 0 10 20 30 40

CAPACITIES AND SPECIFICATIONS

Loading...

Loading...