Checking/Adjusting the Track Tension

1 Prepare the Machine

a Position the machine on firm and level ground.

! WARNING

NEVER position yourself or any part of your body

under a raised machine which is not properly

supported. If the machine moves unexpectedly you

could become trapped and suffer serious injury or be

killed.

INT-3-3-7

b Raise the track to be measured off the ground

(see Cleaning the Tracks, steps 1 and 2). Block

the undercarriage.

c Rotate the track in forward direction only to

ensure that the track is able to rotate freely.

d Stop the engine and remove the starter key.

2 Check the Tension

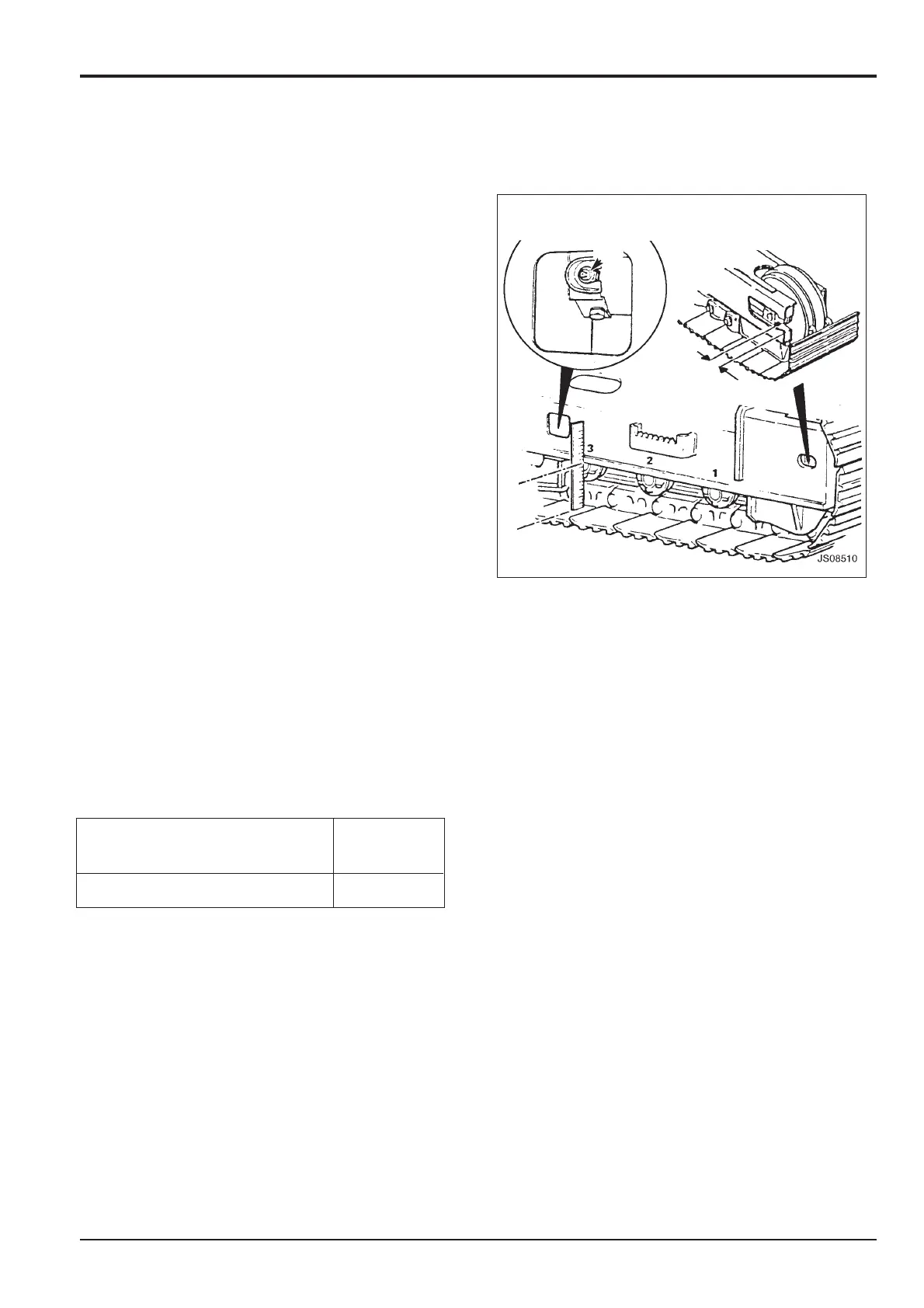

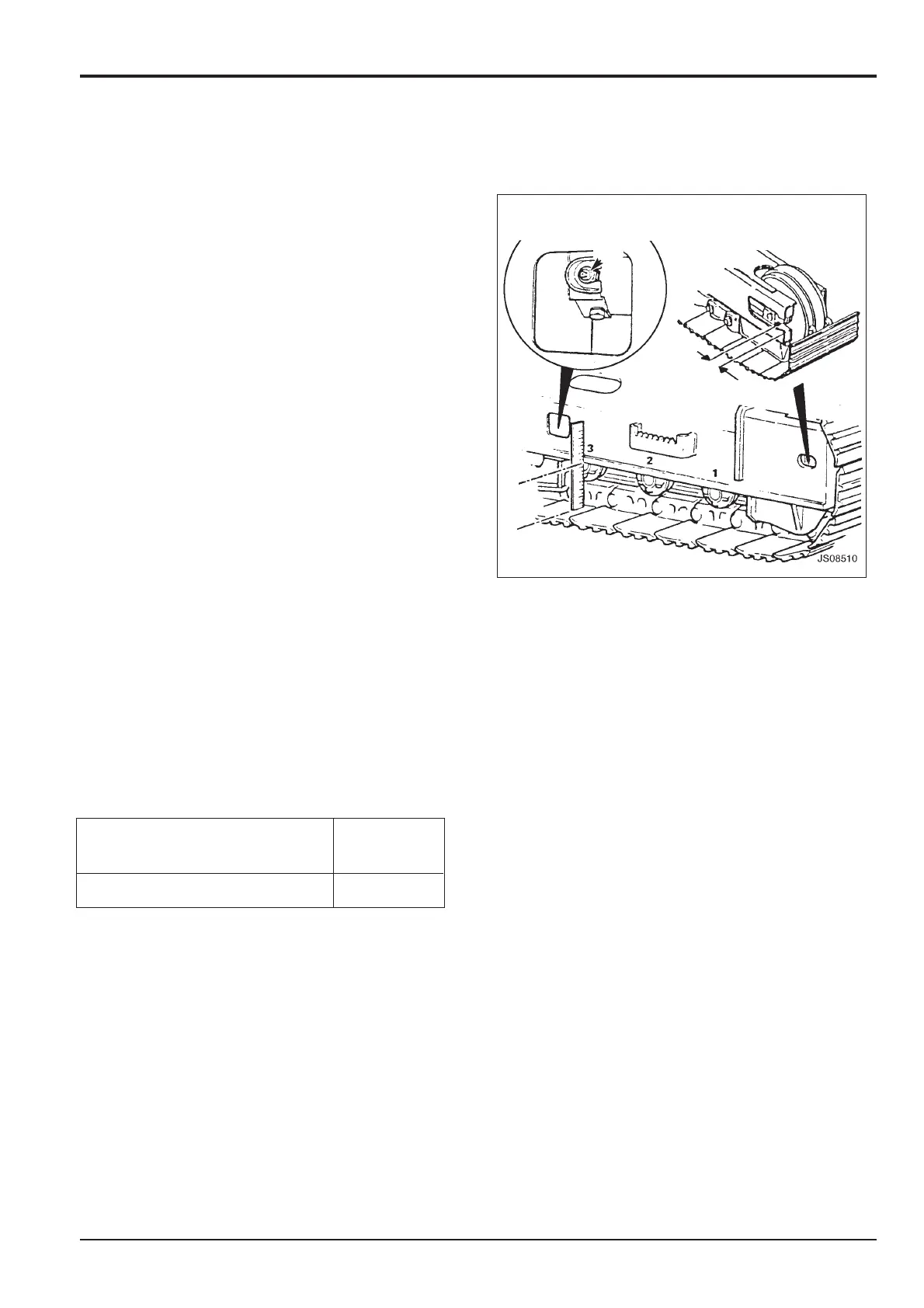

Measure dimension A (see table below), between

track plate and undercarriage, at the third roller

counting from the idler wheel end.

Note: In certain ground conditions, e.g. soft sand and

sticky mud, the chain tension may increase as the machine

is operated and material is packed between the chain and

sprocket/idler wheel. In this case, the tension should be

checked again after approximately 5 minutes tracking.

Dimension A (mm)

Hard Ground (Metal Plates) 180 - 205

(Rubber Plates) 125 - 135

Soft Sand/Sticky Mud 250 - 275

3 Adjust the Track Tension

! WARNING

When opening the check valve always stand to one

side and loosen a little at a time until grease starts to

come out. It you over-loosen too much grease could

spurt out or the valve cover fly out and cause serious

injury.

8-3-4-5

! WARNING

Under no circumstances must the check valve be

dismantled or any attempt made to remove the grease

nipple from the check valve.

8-3-4-9

A

C

B

a If the track is too tight, release a small amount of

grease from the tension unit, by loosening the

check valve B on the tensioner.

Note: A maximum of 3 turns of the check valve should be

sufficient.

b If the track is too slack, pump grease into the

tensioner.

Note: If dimension C is (or becomes) zero before (or

during) tensioning, this indicates that the track and/or its

associated components require attention. Continued use

could cause further serious damage.

4 Lower the Track

Remove the blocks from beneath the undercarriage

and lower the track to the ground using the boom and

dipper controls.

5 Repeat for the Opposite Track

Swing the boom round to the other side and repeat

steps 1 to 4.

Note: The machine shown is typical. The track rollers must

be counted from the front, i.e. the idler end. The example

shows the measurement taken at track roller number three.

Loading...

Loading...