3 - 1

Section 3 Routine Maintenance

9803/6020

Section 3

3 - 1

Issue 1

Greasing

You must grease the machine regularly to keep it working

efficiently. Regular greasing will also lengthen the

machine's working life.

Greasing should be done with a grease gun. Normally, two

strokes of the gun should be enough. Stop greasing when

fresh grease appears at the joint.

For the type of grease to use at each point, see Fluids

and Lubricants - Capacities and Specifications.

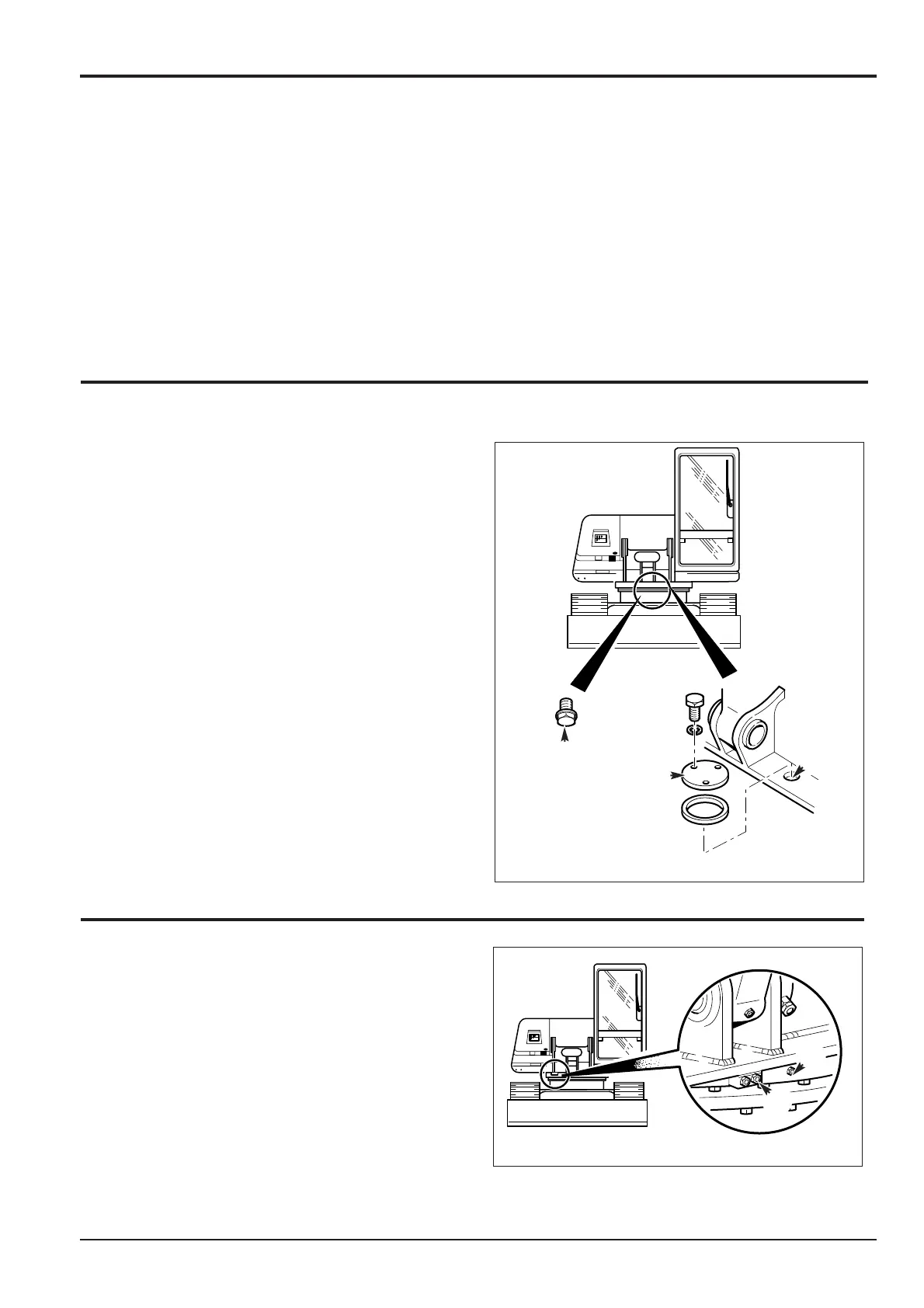

Slew Ring Teeth and Slew Pinion

Ensure slew ring is kept full of grease. Always grease

whenever the machine has been steam-cleaned.

For location of the slew ring gear refer to Component

Location Diagrams at the end of this section.

1 Make the Machine Safe

Stop the engine and remove the starter key.

2 Grease the Slew Ring

a Remove cover A and discharge port plug B.

b Apply grease to the slew ring via aperture C.

3 Slew the Machine

Start the engine and slew the machine a few degrees.

Stop the engine, remove the starter key and apply

grease again.

Repeat until the whole ring is greased. Check that

grease exudes around the entire circumference.

4 Refit the Cover

Refit discharge port plug B and cover A.

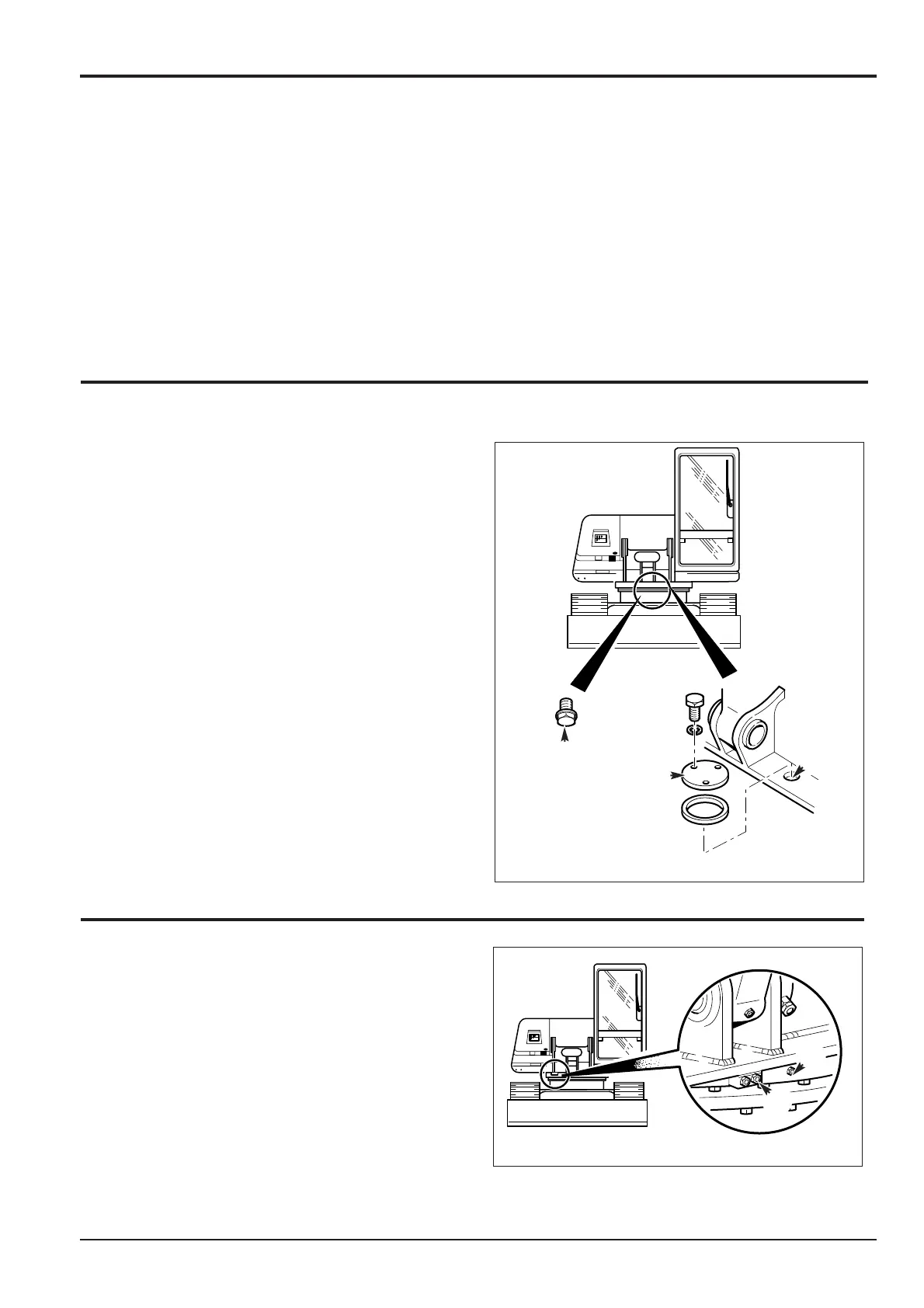

Slew Ring Bearing

Two remote nipples are mounted on plate D. A third nipple

is at E.

Do not mix different types of grease. Keep them separate.

! WARNING

You will be working close into the machine for these

jobs. Lower the attachments if possible. Remove

starter key and disconnect the battery. This will

prevent the engine being started.

8-3-1-3

Loading...

Loading...