AMS-215D, 221D, 215D P TYPE, 221D P TYPE (September, 2003) 1/3

AMS

215D

221D

Z B

Code

S

H

Application

Standard

For heavy-weight materials

Code

5000

6001〜

Subclass

Standard

Subclass

Code

S

P

Code

B

Stitch type

Standard

Perfect stitch

Code

S

L

Feeding frame type

Pneumatic monolithic feeding frame (standard)

Pneumatic separately-driven feeding frame

(with double-stepped stroke function)

Pedal switch

2-pedal unit

PK 2-pedal unit

PK 3-pedal unit

Code

C

K

R

D

L

M

Code

A

C

D

Power supply

100〜120V

Single-phase 200〜240V

220〜415V

200〜240V

3-phase 220〜415V

220〜415V (for CE)

● The machine runs at a sewing speed of 2,500rpm ― the highest speed

achieved in a machine provided with only a medium-sized sewing area.

Its jump speed and thread trimming speed are also extremely high,

effectively doubling those of conventional machines. With its shortened

cycle time, the machine dramatically increases productivity.

● With its direct-drive machine head (beltless) directly joined to a compact

AC servomotor, the machine provides improved responsiveness and

upgraded stop accuracy. Vibration and noise are reduced even during

high-speed operation, thereby achieving a comfortable working

environment.

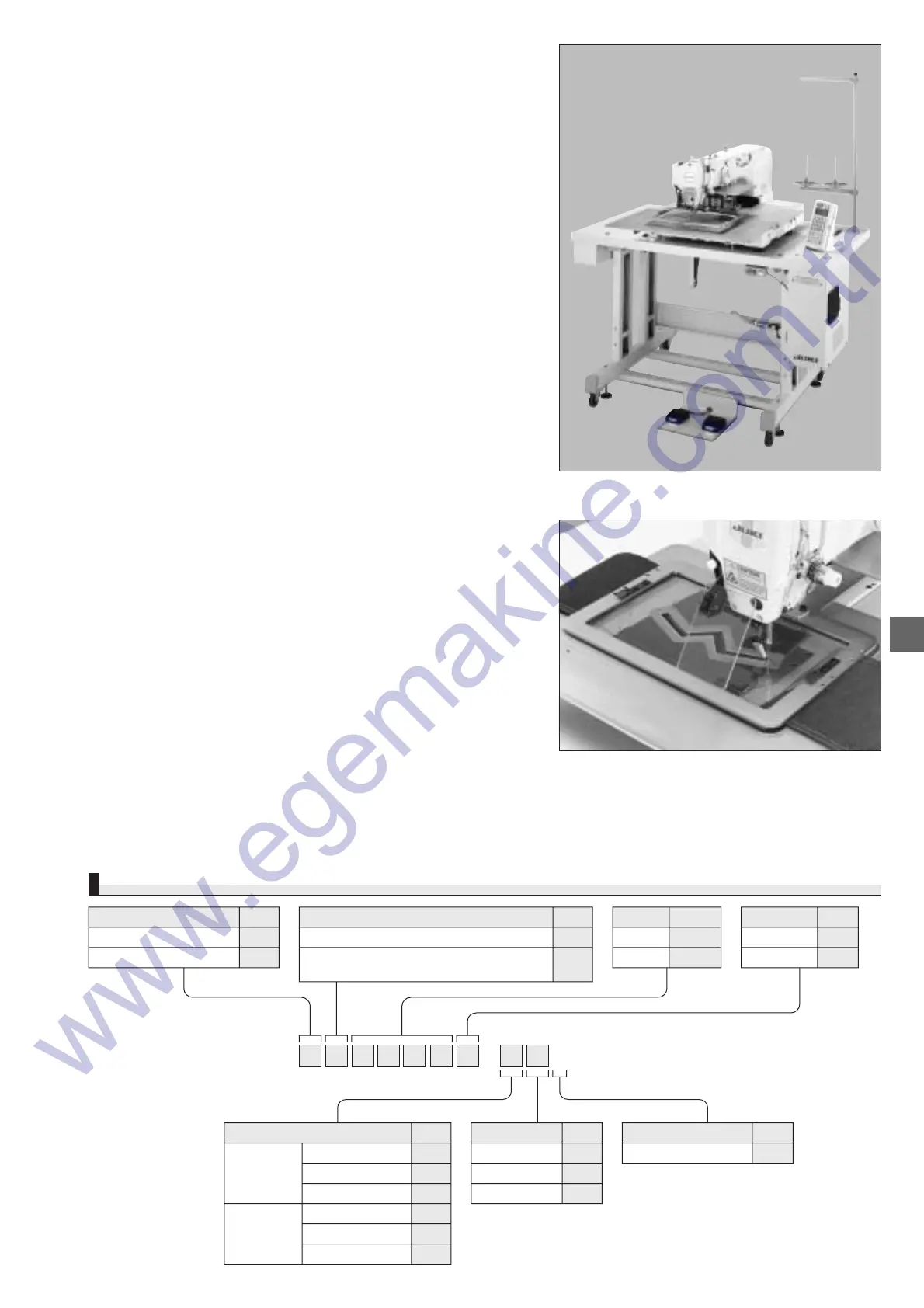

● The machine is configured with JUKI’s unique X Y feed mechanism built

into the bed. Stabilized by the outstanding strength and rigidity of its

feed mechanism, the machine promises the increased feed accuracy

required to produce high-quality seams even in difficult sewing processes

such as decorative pattern stitching.

● Since the X Y feed mechanism is built into the bed, the space under the

arm is both increased and flattened. It allows the operator to place

sewing products easily.

[Space under the arm] AMS-215D: Sewing area+253mm

AMS-221D: Sewing area+246mm

AMS-215D

〈Sewing area: 110mm(L)×220mm(W)〉

AMS-221D

〈Sewing area: 160mm(L)×250mm(W)〉

Computer-controlled Cycle Machine with Input Function

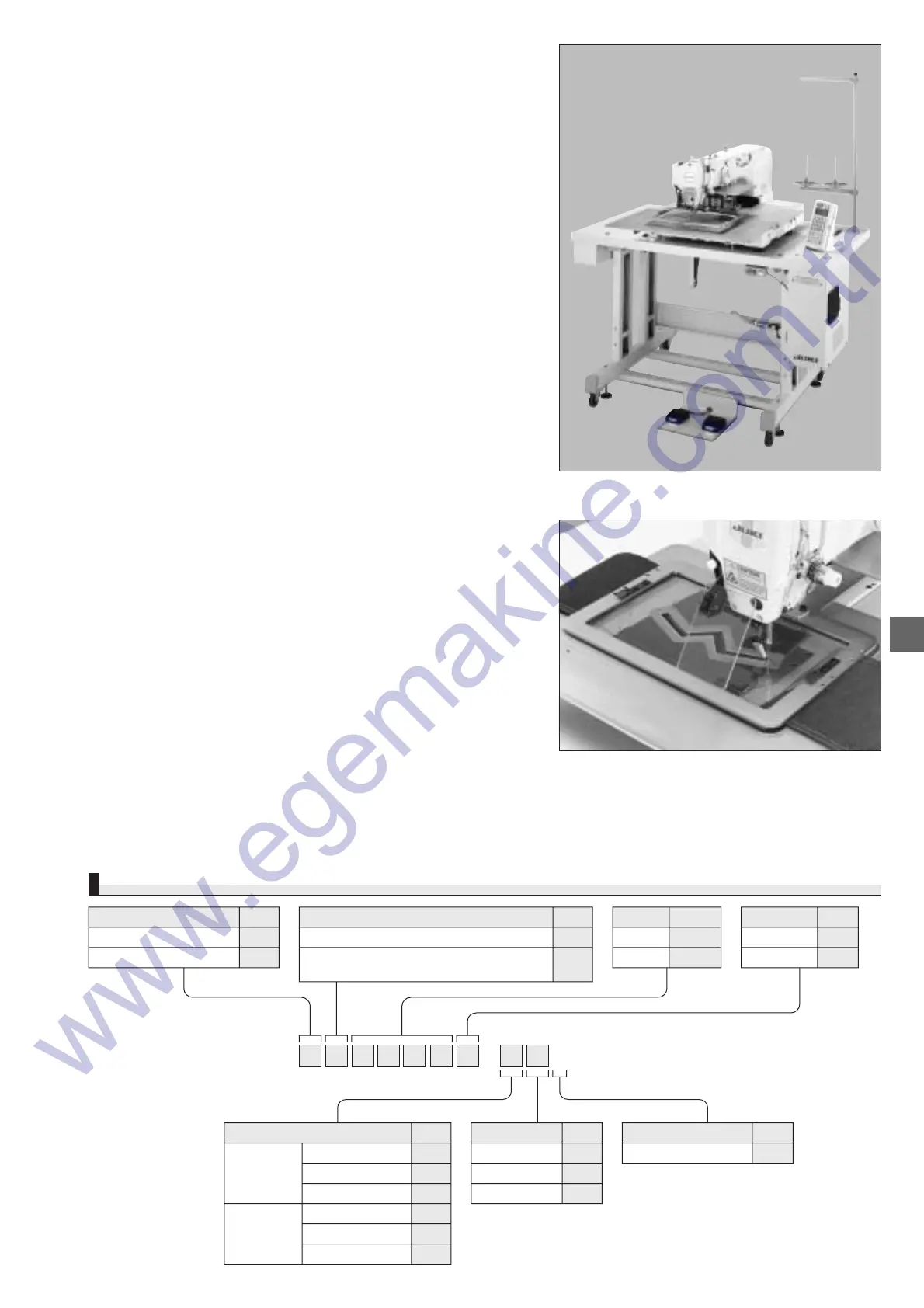

● As a result of JUKI's thorough study of sewing performance, the area in

which hitch stitches appears is reduced to one-third or less of the area

produced with conventional cycle machines. Consequently, the sewing

area finished with perfect stitches is enlarged, and the seam quality of

top stitches is further upgraded.

● Since the feeding direction of the hitch stitching area is restricted to a

range of 5˚to 55˚, each of the four different feeding directions

(0˚, 90˚, 180˚and 270˚) used to sew the four sides of a rectangular label

can be finished with perfect stitching.

AMS-215D P TYPE〈

Sewing area: 110mm(L)×220mm(W)〉

AMS-221D P TYPE

〈Sewing area: 160mm(L)×250mm(W)〉

Computer-controlled Cycle Machine with Input Function

for Wider-area Perfect Stitching

AMS-221D

AMS-221DSS

WHEN YOU PLACE ORDERS

*Select "A" or "C" for the monolithic

feeding frame (specification: S) or "D"

for the double-stepped stroke

feeding frame (specification: L).

Control panel

English and pictograph

Loading...

Loading...