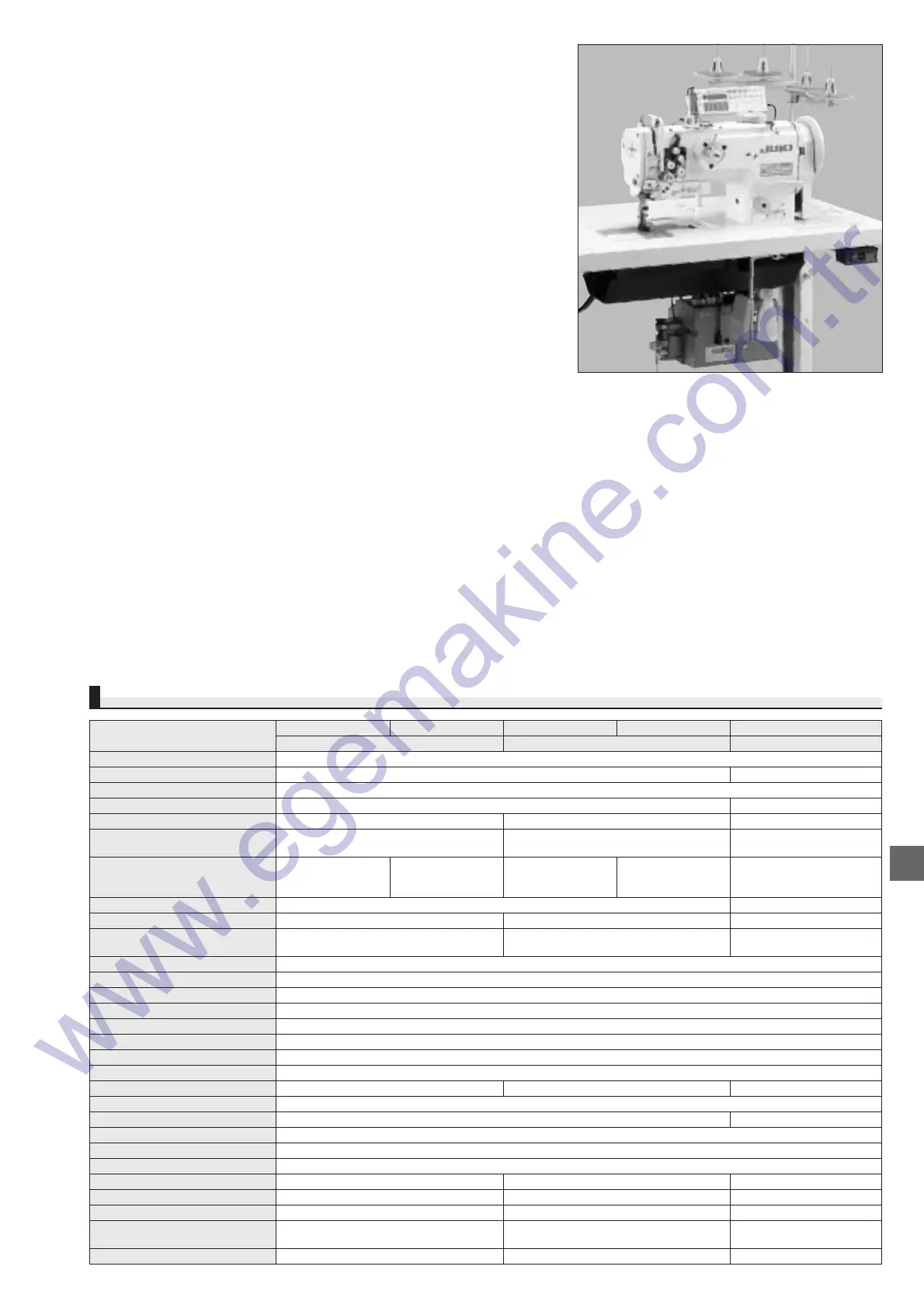

LU-1560N, 1560N-7, 1565N, 1561N, 1561N-7 (September, 2003) 1/5

Model name

LU-1560N LU-1561N LU-1560N-7 LU-1561N-7 LU-1565N

− With automatic thread trimmer

With organized split needle bar

Application For heavy materials

Max. sewing speed 2,500rpm 2,000rpm

Max. stitch length 9mm (Normal/Reverse feed)

Needle bar stroke 36mm 33.4mm

Lift of the presser foot By hand: 9mm, By knee: 16mm (max.) By hand: 9mm, Auto: 16mm

By hand: 9mm, By knee: 13mm (max.)

Auto-lifter Option

Provided as standard

(Pneumatic auto-lifter: AK123B)

Option

Needle gauge

Organized split needle bar − Provided as standard

Alternating vertical movement 2.5〜6.5mm 1〜6.5mm 2.5〜6.5mm

Dial for adjustment of alternating

vertical movement

− Provided as standard −

Thread take-up Slide type

Hook Vertical-axis double-capacity hook

Needle (at the time of delivery) 135×17 (Nm160) Nm125〜Nm180

Thread #30〜#5, B46〜B138, Nm=60/3〜20/3

Locus of feed Rectangular feed

Needle thread tension box Single-tension method

Pitch changing method By dial

Bobbin thread winder Built on the machine head

Knee-lifter mechanism Built on the machine head − Built on the machine head

Safety mechanism Provided as standard (Reset with the push of a button)

Lubrication Automatic By an oiler (hook: automatic)

Lubricating oil JUKI New Defrix Oil No.2 (equivalent to ISO VG32)

Distance from needle to machine arm

255mm

Bed size 517mm×178mm

Weight of the machine head 45kg 51kg 45kg

Automatic reverse feed function Option Provided as standard −

Compressed air and air consumption

− 0.5MPa {5kg/F} • 0.3NR/min −

Power requirement −

Single-phase 100〜120V, 220〜240V

3-phase 200〜220V, 220〜240V

−

Power consumption − 550VA −

SPECIFICATIONS

LU-1560N-7-0BBAA/XC-E500

4.8mm, 6.4mm, 7.9mm,

9.5mm, 12.7mm

(3/16, 1/4, 5/16, 3/8, 1/2)

6mm, 8mm, 10mm,

12mm

4.8mm, 6.4mm, 7.9mm,

9.5mm, 12.7mm

(3/16, 1/4, 5/16, 3/8, 1/2)

6mm, 8mm, 10mm,

12mm

4.8mm, 6.4mm, 7.9mm

(3/16, 1/4, 5/16)

2-needle, Unison-feed, Lockstitch Machine with Vertical-axis Large Hooks

[Gauge for standard]

LU-1560N

(with automatic lubricating mechanism)

LU-1560N-7

LU-1565N

(with organized split needle bar)

[Gauge for LU-2200]

LU-1561N

LU-1561N-7

(with automatic lubricating mechanism

and automatic thread trimmer)

(with automatic lubricating mechanism

and automatic thread trimmer)

● The new mechanism with a rectangular feeding motion

promises consistent feed of materials of all thickness without

the risk of stitch gathering.

The reduced lift of the feed dog helps prevent the material

from flopping and reduces operating noise and vibration.

〈Rectangular feed〉

Compared with the elliptical feed, the rectangular feed helps

reduce gathered stitches.

● With the adoption of a new rectangular feed mechanism, an

alternating vertical movement mechanism, and a unison feed

mechanism, the machine can feed heavy materials powerfully

and smoothly. Well tensed seams are consistently produced

without pitch errors.

● LU-1560N, LU-1561N, LU-1560N-7, LU-1561N-7

•Automatic lubricating mechanism improves maintainability.

The sub oil pan and double filter prevent dust from entering

the oil.

● LU-1560N-7, LU-1561N-7

•The machine comes with JUKI's proven thread trimming

mechanism. With its robust knife and cam configuration,

the thread trimmer reliably cuts threads as thick as #5.

● LU-1565N

•The organized split needle bar mechanism makes it possible

to stop or reset the left or right needle by operating a one-

touch utility lever.

•The machine produces neatly finished stitches at corner parts

of the material.

Loading...

Loading...