DLD-5430N, 5430N-7 (September, 2003) 1/2

DLD-5430N DLD-5430N-7

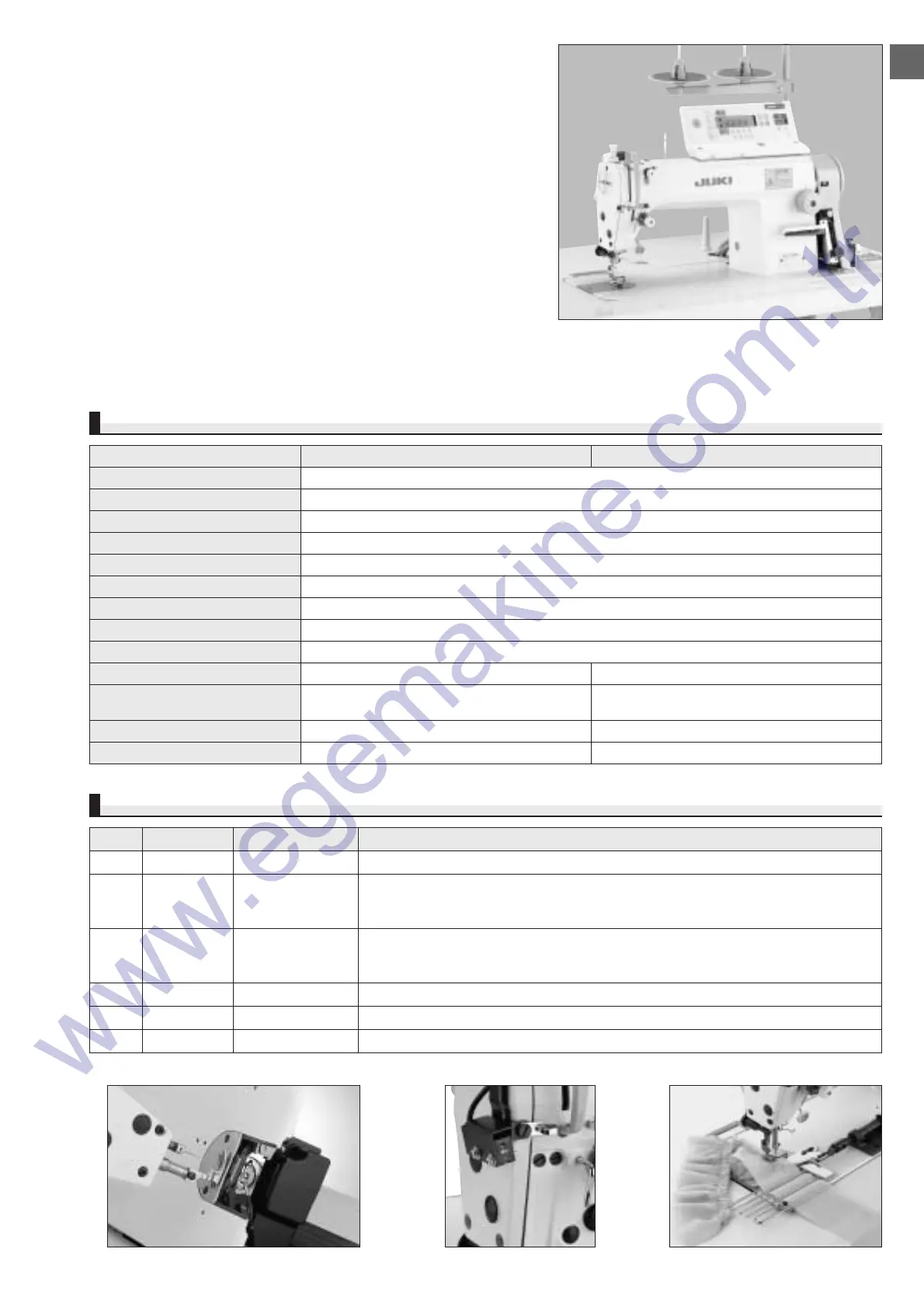

Remaining bobbin thread detector (AE-4) Gathering attachment (Q036)Material edge sensor (ED-2)

● With optional devices such as a partial shirring device (PF-7) and

gathering attachment mounted on the machine, beautiful gathers

can be sewn with enhanced efficiency. This new, upgraded-quality

machine provides not only operating comfort, but also dramatically

improved seam quality, further cost reduction, and excellent

productivity.

● The thread take-up mechanism, thread path components and

differential feed mechanism have all been improved. Thanks to

these improvements, partial shirring can be performed with

minimum tension applied to the material, thus leading to greater

flexibility in responding to different types of material.

DLD-5430N

DLD-5430N-7

(with automatic thread trimmer)

1-needle, Differential-feed, Lockstitch Machine

Model

AK85

AE-4

*

ED-2

PF-7

Q036

―

Part No.

―

GAE-040000A0

―

―

―

112-43763

Description

Auto-lifter

Remaining bobbin

thread detector

Material edge sensor

Partial shirring device

Gathering attachment

Micro-lifter (asm.)

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

The partial shirring device permits very easy shirring.

For high-quality gathering, both effectively and consistently.

This device can be installed on the back of the faceplate. It is very convenient for frequent use.

OPTIONS

*To retrofit the AE-4 to your existing machine, I/O unit A (part number: 400-06080), which is separately available, is required.

SPECIFICATIONS

Model name

Max. sewing speed

Max. stitch length

Max. top-feed amount

Needle bar stroke

Lift of the presser foot

Needle (at the time of delivery)

Hook

Lubrication

Lubricating oil

Automatic reverse feed function

Power requirement

Power consumption

Weight

4,500rpm

5mm

Shirring 1:1.5 (max. 1:3

*

), Stretching 1:0.5

30.7mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#14), For JE: 134 (Nm90)

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

―

―

―

Machine head: 29kg

Provided as standard

Single-phase 100〜120V, 200〜240V

3-phase 200〜240V

650VA

Total weight: 82kg

*This ratio applies provided that the stitch length does not exceed 2.5mm.

DLD-5430N-7-WB/CP-160A

Loading...

Loading...