Loading...

Loading...

Do you have a question about the Keithley Series 2600 and is the answer not in the manual?

| Model | Series 2600 |

|---|---|

| Measurement Functions | Voltage, Current, Resistance, Power |

| Resolution | Up to 6.5 digits |

| Current Source Range | Up to 10A |

| Communication Interfaces | GPIB, USB |

| Applications | Semiconductor testing |

| Category | Source Measure Unit (SMU) |

| Channels | Single or Dual Channel (varies by model) |

Discusses system configurations for application programs.

Details system hardware configuration.

Describes the overall hardware configuration of a test system.

Discusses sensing methods for optimizing accuracy.

Explains how to visualize data using graphing.

Introduces tests for two-terminal devices.

Details instrument connections for two-terminal device tests.

Explains testing voltage coefficient of resistors.

Details testing capacitor leakage current.

Explains diode characterization tests.

Introduces bipolar transistor tests.

Details instrument connections for bipolar transistor tests.

Explains testing common-emitter characteristics for transistors.

Explains generating Gummel plots for transistors.

Discusses methods for measuring DC and AC current gain.

Explains testing transistor leakage current.

Introduces FET testing.

Details instrument connections for FET tests.

Explains common-source characteristics for FETs.

Details transconductance testing for FETs.

Explains methods for determining FET threshold voltage.

Introduces substrate bias concepts.

Details instrument connections for substrate bias.

Discusses SMU substrate biasing methods.

Explains substrate bias for BJTs.

Introduces high power testing challenges.

Details test setup for high current tests.

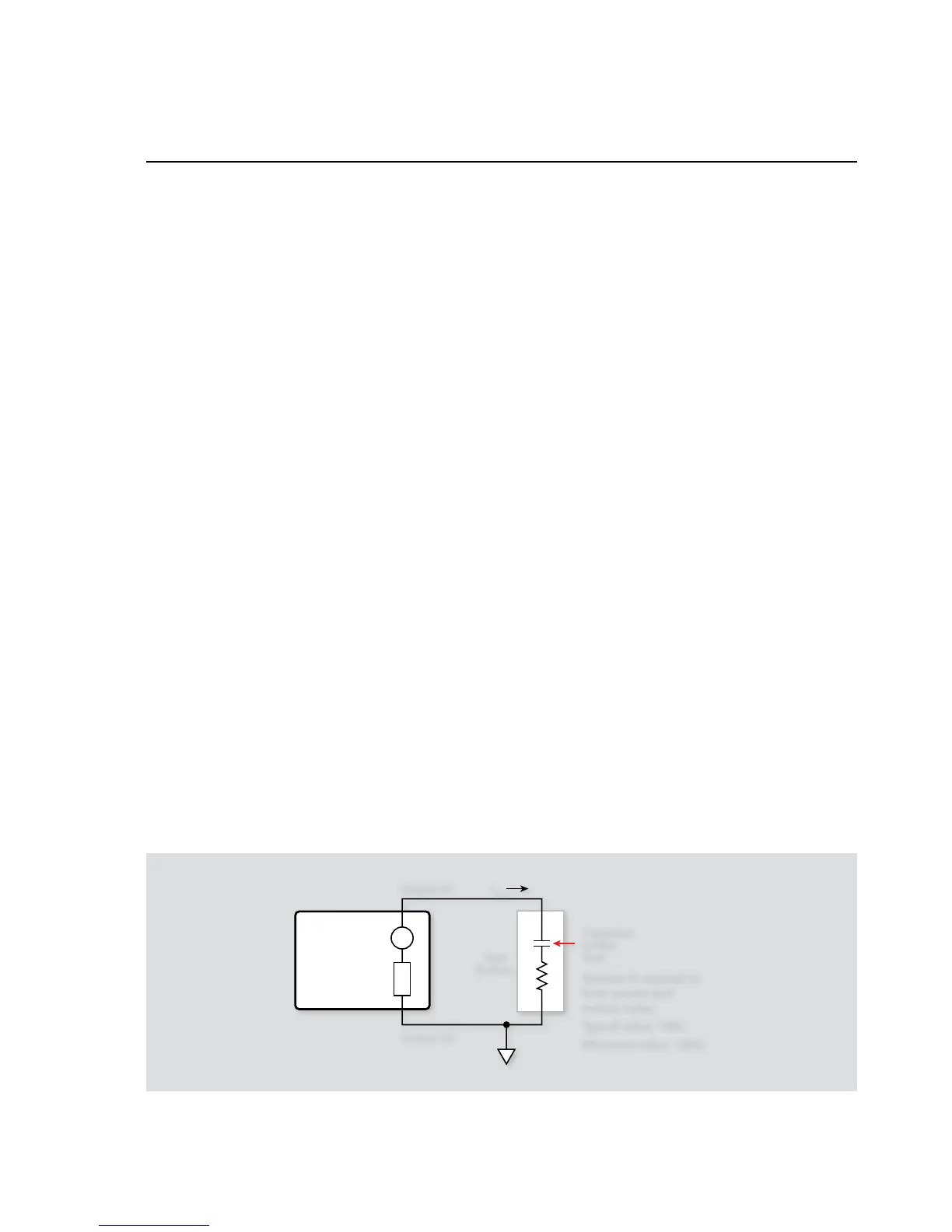

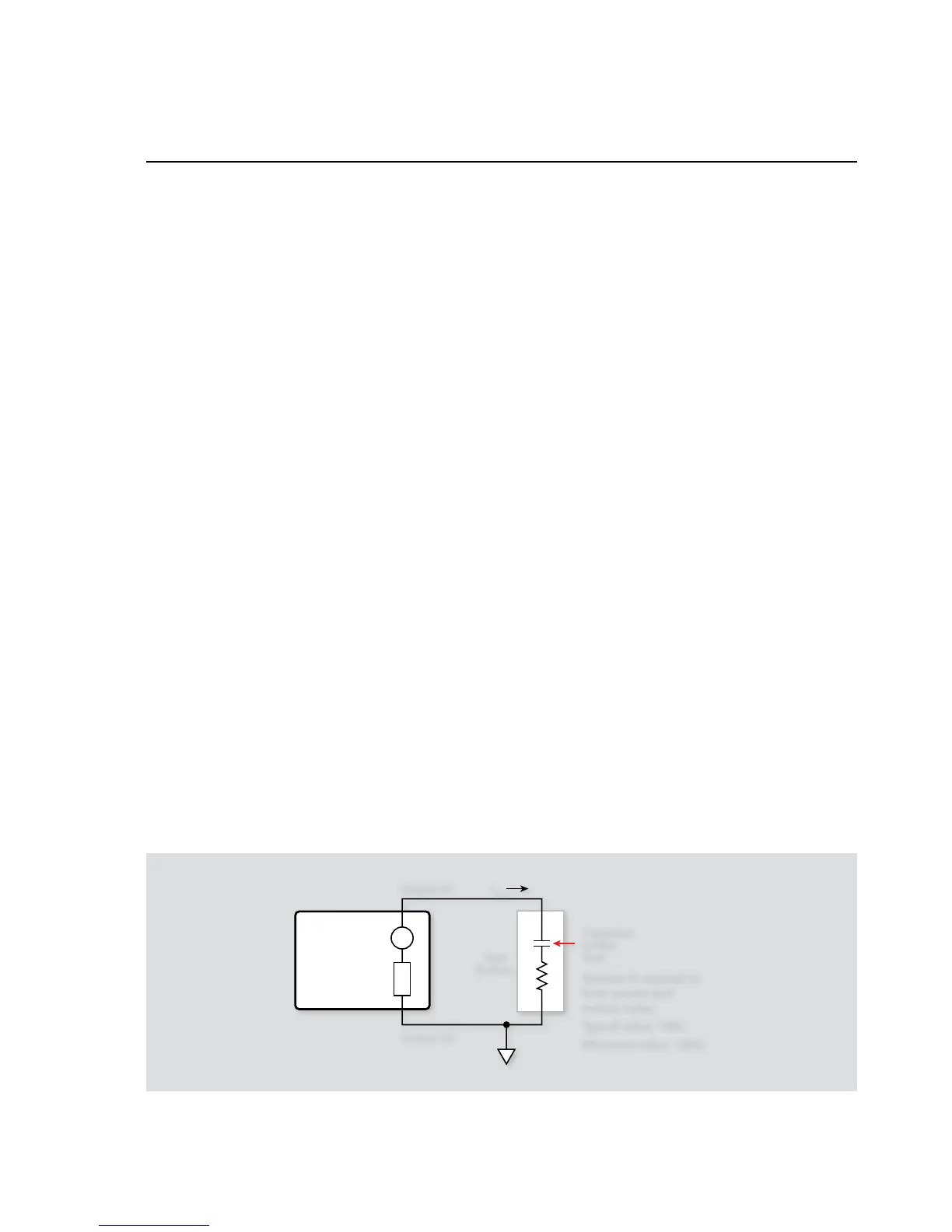

Shows high current sourcing with voltage measurement.

Details instrument connections for high power tests.

Details test setup for high voltage tests.

Shows high voltage sourcing with current measurement.

Contains scripts for two-terminal device tests.

Contains scripts for bipolar transistor tests.

Contains scripts for high power tests.

Contains scripts for FET tests.

Contains scripts for substrate bias tests.