2-5

SECTION 2

Two-terminal Device Tests

2.4.6 Program 2 Description

At the start of the program, the instrument is reset to default con-

ditions, the error queue, and data storage buffers are cleared. The

following configuration is then applied before the data collection

begins:

Source V, DC mode•

Local sense•

10mA compliance, autorange measure•

1 NPLC Line cycle integration•

vsrc:

• 40V

The instrument then sources

vsrc

, checks the source for compli-

ance in the function named

Check _ Comp()

, and performs a

measurement of the current if compliance is false.

The function

Calc _ Val()

then performs the calculation of

the leakage resistance based on the programmed source value

and the measured current value as described in paragraph 2.4.2,

Leakage Resistance Calculations.

The instrument output is then turned off and the function

Print _ Data()

is run to print the data to the TSB window.

Note: If the compliance is true, the instrument will abort the pro-

gram and print a warning to the TSB window. Check the DUT

and cabling to make sure everything is connected correctly and

re-run the test.

2.5 Diode Characterization

The System SourceMeter instrument is ideal for characterizing

diodes because it can source a current through the device, and

measure the resulting forward voltage drop (V

F

) across the device.

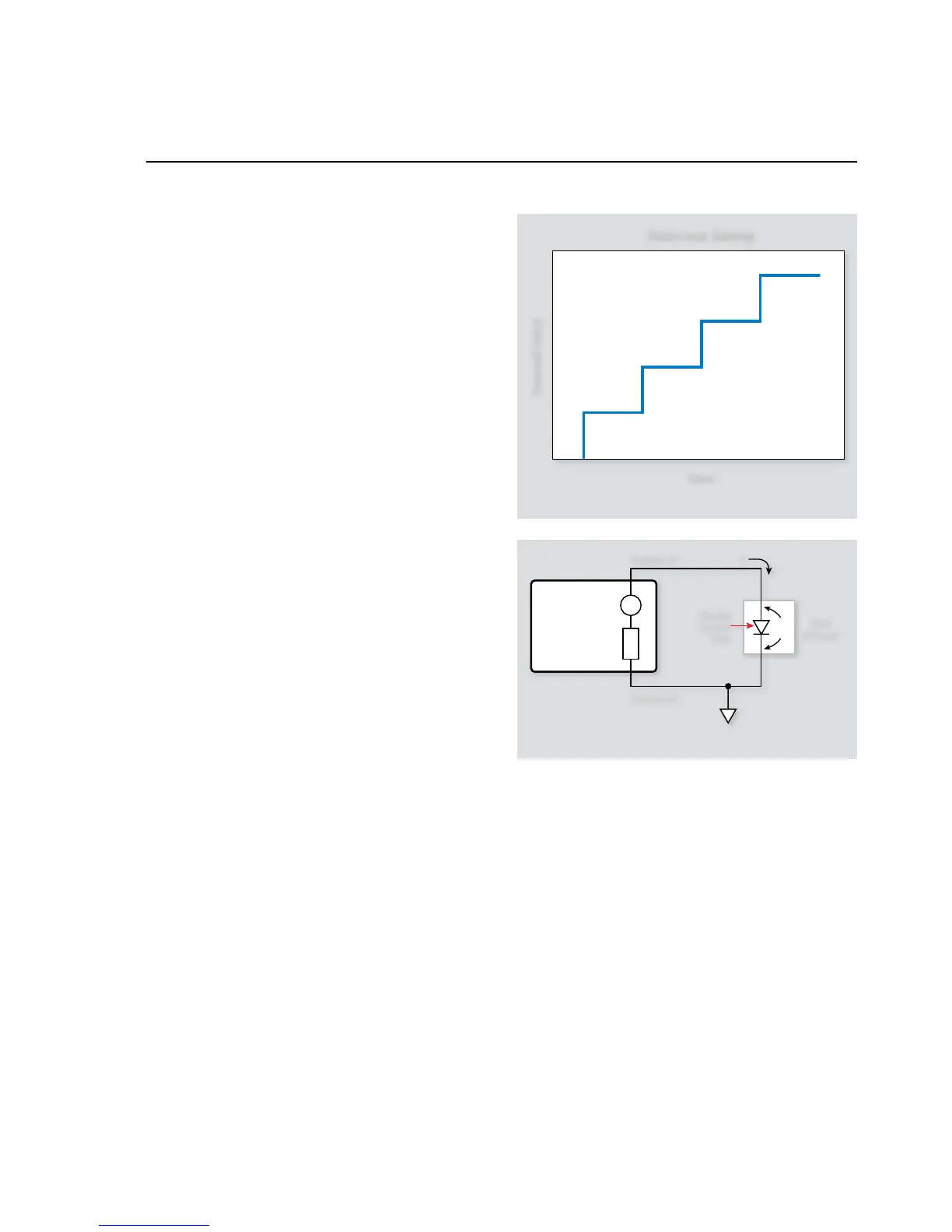

A standard technique for diode characterization is to perform a

staircase sweep (Figure 2-4) of the source current from a starting

value to an end value while measuring the voltage at each current

step. The following paragraphs discuss the test configuration and

give a sample test program for such tests.

2.5.1 Test Configuration

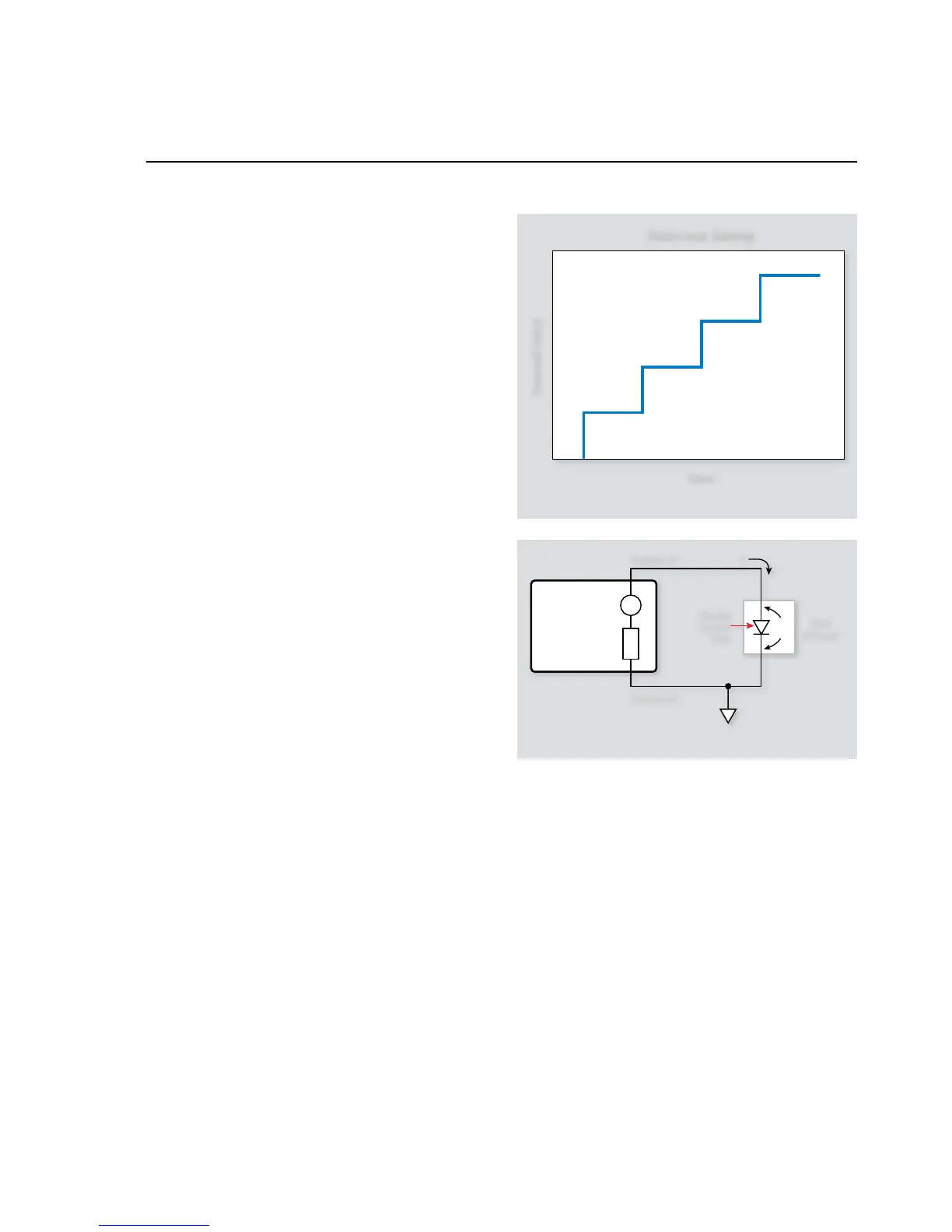

Figure 2-5 shows the test configuration for the diode character-

ization test. The System SourceMeter instrument is used to source

the forward current (I

F

) through the diode under test, and it also

measures the forward voltage (V

F

) across the device. I

F

is swept

across the desired range of values, and V

F

is measured at each cur-

rent. Note that the same general configuration could be used to

measure leakage current by reversing the diode, sourcing voltage,

and measuring the leakage current.

2.5.2 Measurement Considerations

Because the voltages being measured will be fairly small (≈0.6V),

remote sensing can be used to minimize the effects of voltage

drops across the test connections and in the test fixture. Remote

sensing requires the use of the Sense connections on the System

SourceMeter channel being used, as well as changing the code to

reflect remote sensing. For more information on remote sensing,

see the Series 2600 Reference Manual.

2.5.3 Example Program 3:

Diode Characterization

Program 3 demonstrates the basic programming techniques for

running the diode characterization test. Follow these steps to use

this program:

Loading...

Loading...