12-12 CK20

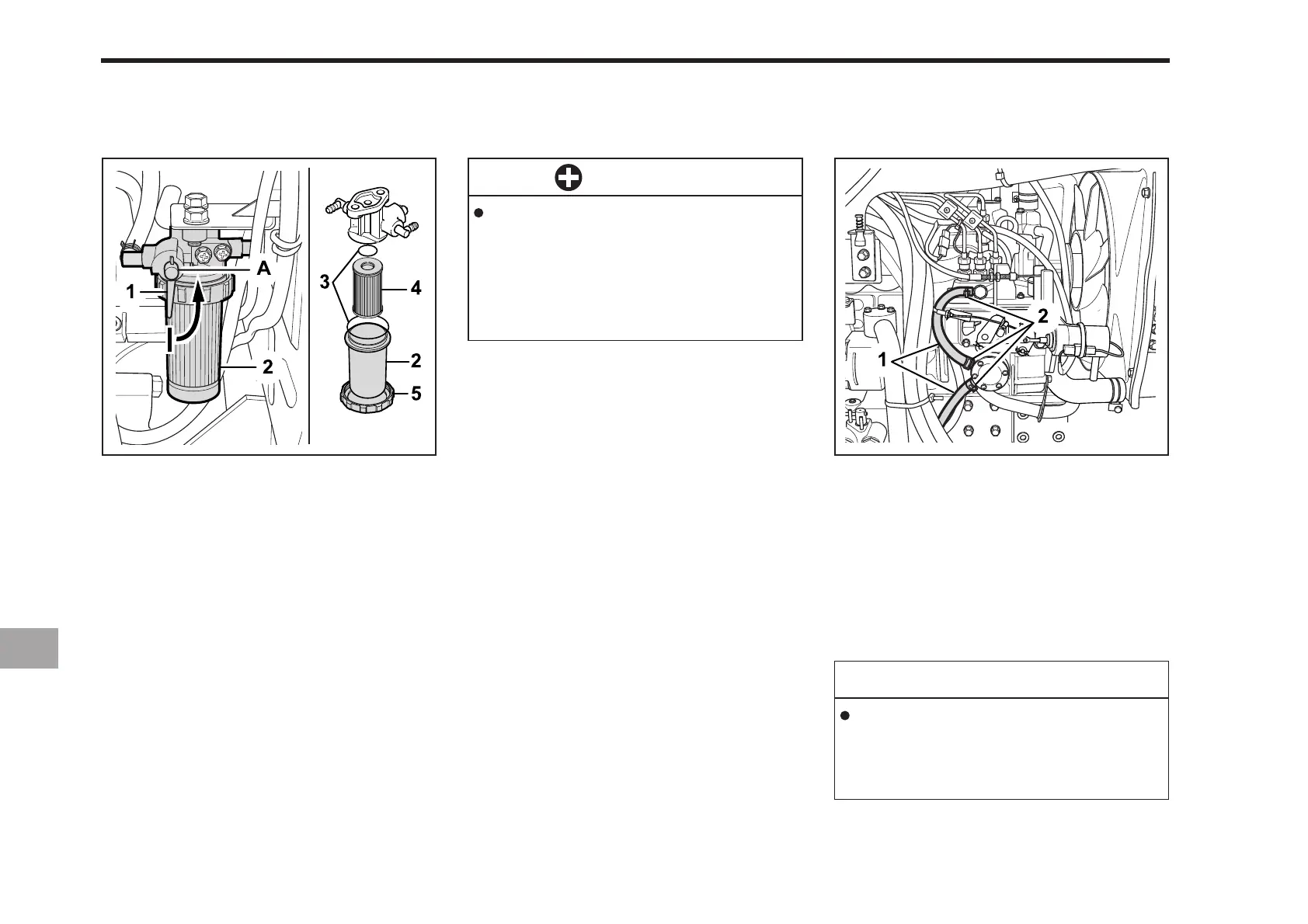

196OC24A

(1) Fuel Lines (2) Clamp Bands

CHECKING FUEL LINE

1. Check to see that all lines and hose

clamps are tight and not damaged.

2. If hoses and clamps are found worn

or damaged, replace or repair them at

once.

NOTE

If the fuel line is removed, be sure to

properly bleed the fuel system.

(See “Bleeding Fuel System” in as re-

quired maintenance)

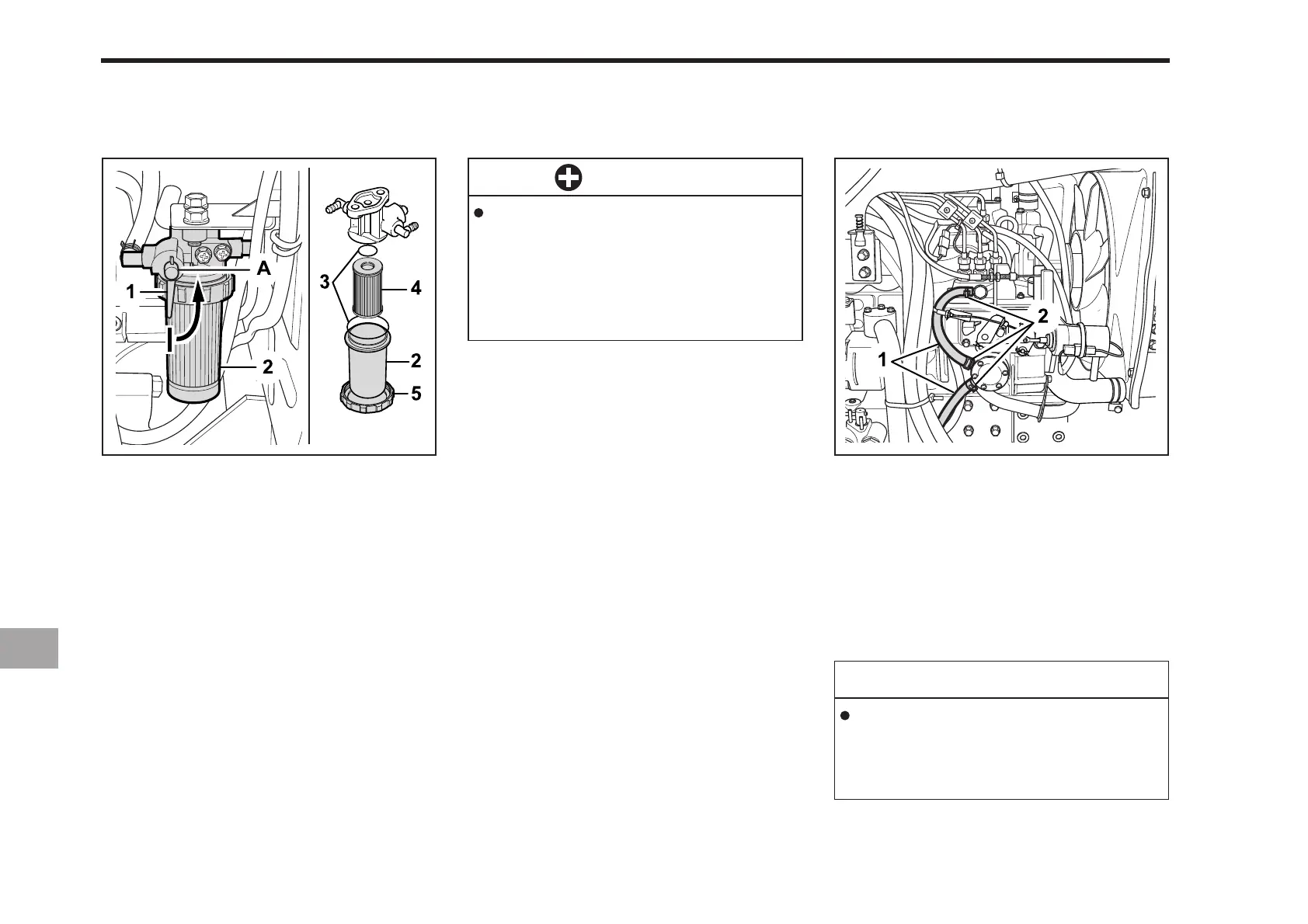

196OC21A

(1) Fuel Cock

(2) Fuel Filter Bowl

(3) O-Ring

(4) Filter Element

(5) Spring

(6) Filter Bowl

(7) Screw Ring

(A) Close

CLEANING FUEL FILTER

This job can be done in the field but in a

clean place.

1. Close the fuel cock.

2. Unscrew the ring and remove the filter

bowl. Rinse the inside with kerosene.

3. Take the filter element out and dip it in

the kerosene to clean.

4. After cleaning you should reassemble

the filter element, making sure that it is

free from dust and dirt.

5. Bleed the fuel system. (See “Bleeding

the fuel System” in the service

section)

IMPORTANT

If dust and dirt enters the fuel

system, the fuel pump and injec-

tion nozzles are subject to pre-

mature wear. To prevent this, be

sure to clean the fuel filter bowl

and element periodically.

Loading...

Loading...