KiSC issued 09, 2007 A

0.04

to

0.07

mm

0.0016

to

0.0028

in.

·

-

--

-

-

--

---

0.10

mm

0.0039

in.

0

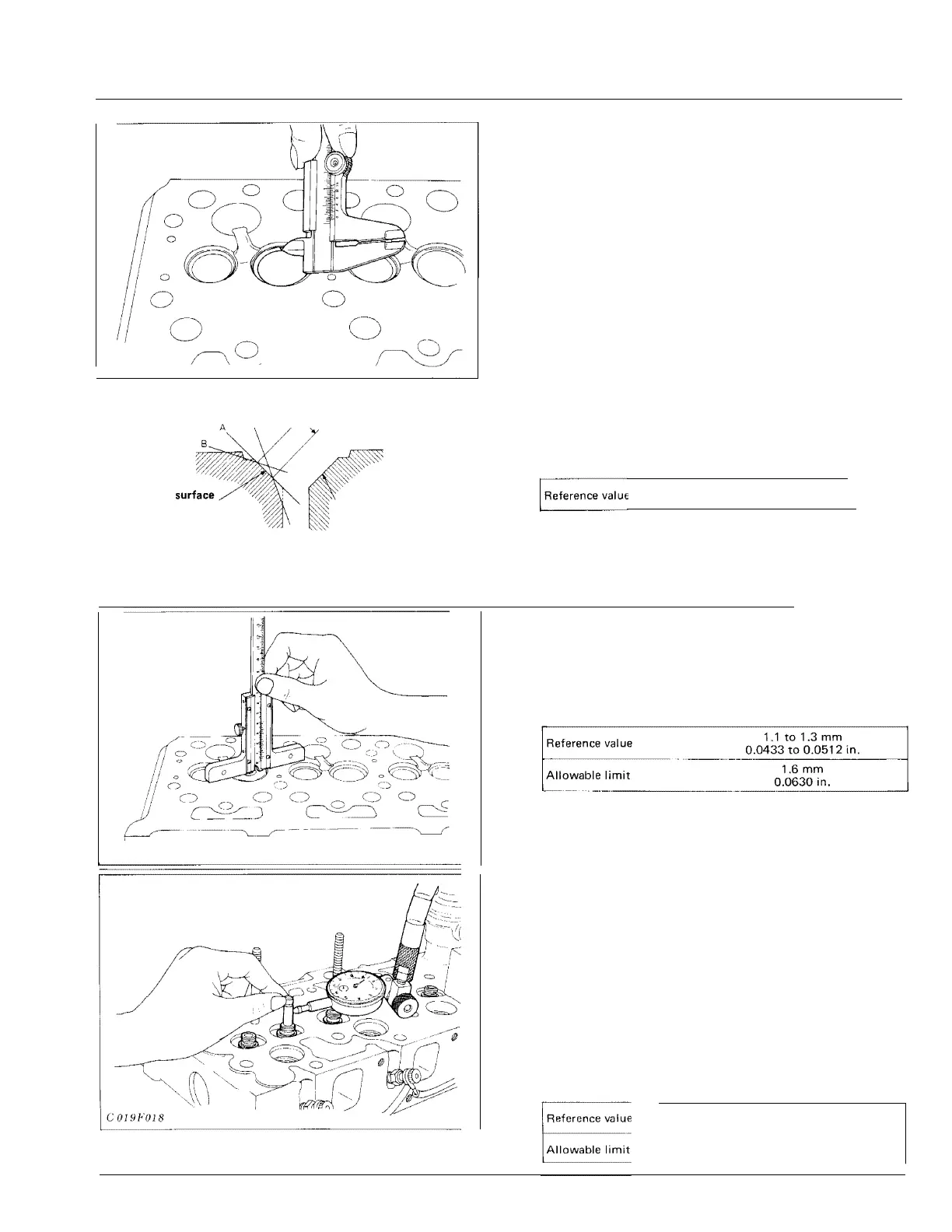

Checking and Refining Valve Seat Width

1)

Clean the val ve seat su rface.

2)

Measu re the width of the seat usi ng a set of vern ier

cal

i

pers.

3)

Appl y red lead on the val ve to check if the seat is scratch-

ed or not.

(

A) How to repair the valve seat

C

(a) Valve contacting width

•

To correct the dimensions of the valve seat usi ng a valve

seat cutter, follow the steps.

1) Use a cutter suitable for the valve guide and the valve

seat. (0.785 rad.(45°),¢8m m(0.315

in.))

2)

Grind off the front surface of the valve seat by 0.262

rad. ( 15°), since the seat surface becomes wider than

before.

3)

Grind off the rear surface of the seat by usi ng 1.134 or

1.308 rad. (65 or 75°) cutter to finish the seat 2.1 m m

( 0.0827

i

n .) wide.

4) Reface the valve.

(b)

Corrected

of valve seat

(cl U ncorrected surface

of va Ive seat

C 019 F016

(d)

A-0.785

rad.(45°)

cutter

B

-0.262

rad.(15°)

cutter

C-1.134

or

1.308

rad.(65

or 75°) cutter

51

C+)

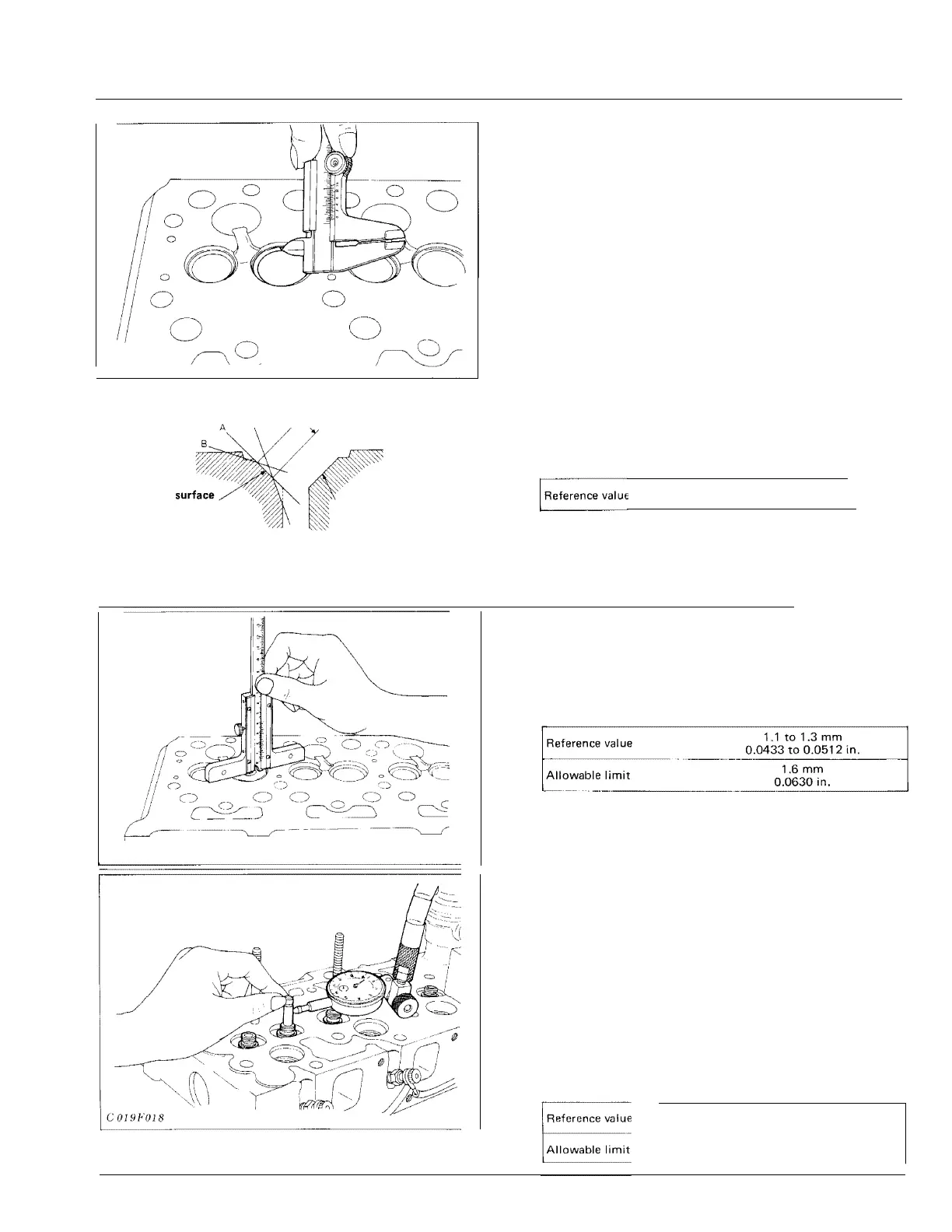

Checking Valve Recessing

1)

Clean the face of the val ve.

2)

Measu re the si n ki ng with a depth gau ge.

3)

I

f the measu rement exceeds the al

l

owa ble

l i

m

i

t, repl ace.

C 019

01

(i)

Checking Stem Guide Clearance

1)

Remove carbon from the val ve gu

i

de.

2)

Af ter ma ki ng su re th at the val ve stem is straight,

i

nsert

the val ve

i

nto the val vegu ide.

3)

Measu re the stem gu ide clea rance wi th a d ial gauge.

4)

I

f the measu rement exceeds the al

l

owa ble

l i

m

i

t, repl ace

the stem gu

i

de and the val ve.

( Note for replacing )

•

I

nlet and exhaust valve guide resem ble each other

i

n

shape. To

i

nstall them, be su re that they a re on the proper

side.

019

01 5

2.1

mm

0.0827

in.

Loading...

Loading...