KiSC issued 09, 2007 A

(A)

Crank pin for undersized bearing

(a) 3.SR

±

0.2mm (b) Oil hole must be 1 to 1.5Rmm

(0.1378R

±

0.0079

in.)

(0.0394

to

0.0591R

in.)

Check ing Oi

l

Clearance between Crank Pi ns

and Crank Pin Bearings

1)

Paste a press gauge with grease on the c rank pin bearing.

2)

Tighten the connecting rod onto the crank pin to the

specified torque

(36.3

to

41.2

N-m.,

3.7

to

4.2

kgf,m.,

26.8 to 30.4 lb.ft.)

3)

Remove the large end cap carefu Ily, and measure the

depression of the press gauge with a sheet of gauge (paper) .

4)

If the standard-size bearing cannot be employed due to

exessive wear of the crank pin, employ undersize bearing.

For undersize bearing use, follow the precautions noted

below.

1.

Cut corner radius of the crank pin to precisely

3.5R±

0.2

mm ( 0.1378R±0.0079 in.)

2.

Be sure to chamfer the oil hole circumference with an

oil stone.

3.

The crank pin must be fine-finished to higher than

'vVVv

( 0.4S) .

0071 F005

(cl

3.SR

±

0.2mm

(0.1378R

±

0.0079

in.)

( Note for measu ri ng)

1)

Fasten the cran kshaft so that it does not tu rn.

2)

Do not

i

nsert the press gauge

i

nto the cran k pin hole.

3)

Crank pi n metal measuring poi nts are shown below:

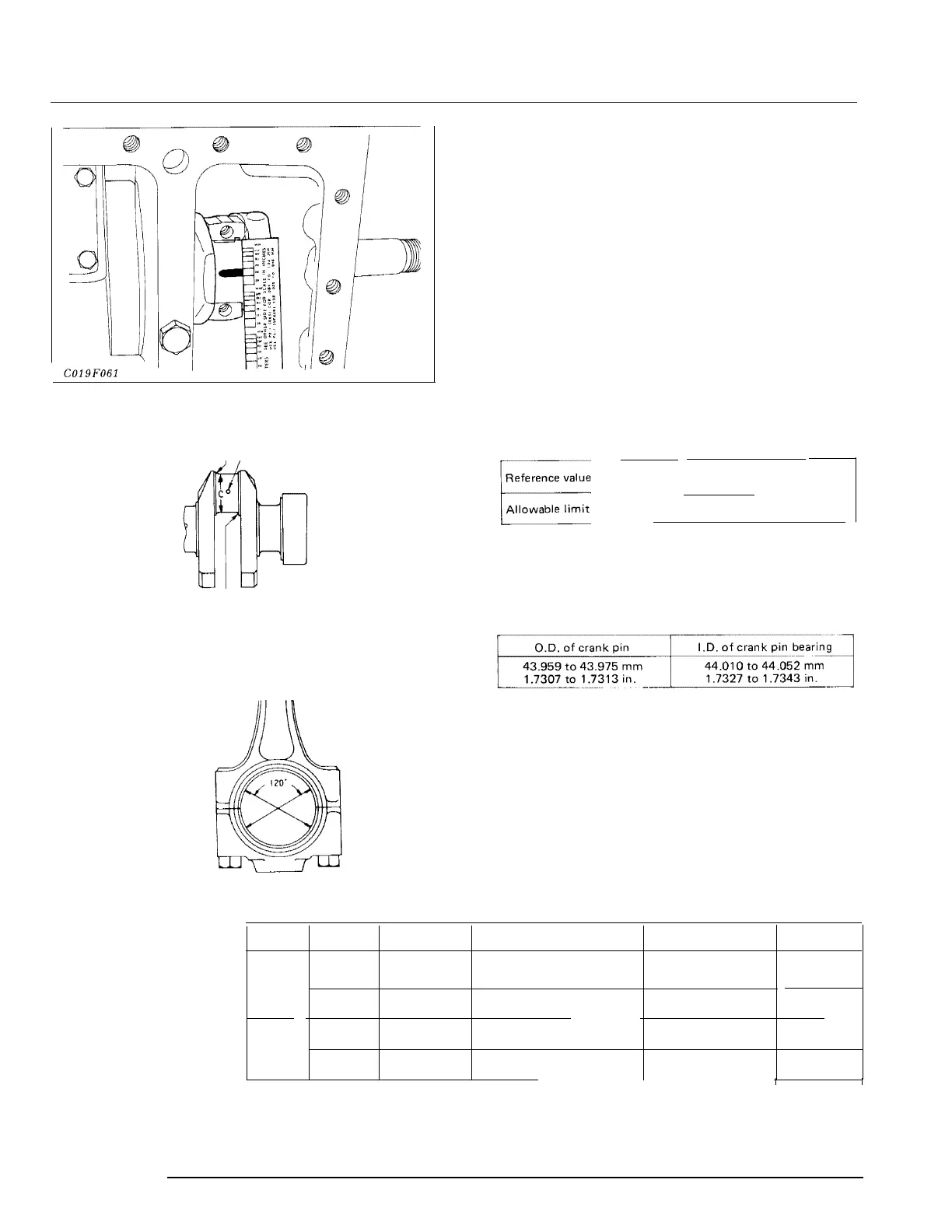

(B)

Crank pin measuring points

COJ 9F062

66

Model

Undersize Code Numbe

01102-8

01302-B

V1502-B

V1702-B

Part Name

··-

·

-

·

---

15221-2297-1

Crank pin bearing 0.2 minus

15221-2298-1

Crank

in bearin

0.4 minus

15471-2298-1

Crank

in bearin

0.4 minus

Crank pin dia. C

Bearing Mark

(Shown in Fig.)

43.759 to 43.775 mm

1.7228 to 1.7234 in.

43.559 to 43.575 mm

1.7149 to 1.7156 in.

I

43.759 to 43.775 mm

1.7228 to 1.7234 in.

43.559 to 43

575 mm

0.2 mm

0.0079 in.

0.4 mm

0.0157 in.

0.2 mm

0.0079 in.

0.4 mm

0.0157 in.

020

us

040

us

020

us

040

us

-·-

15471-2297-1

Crank

in bearin

0.2 minus

D1402-B

V1902-B

·-·"""'"'''"""'

....

_

''

'

·

--·-"-'""'·

--

-

-···

--·-

1.7149 to 1.7156 in.

0.035 to 0.093 mm

0.0014 to 0.0037

·-

--

--·----<

0.20 mm

0.0079 in.

Loading...

Loading...