KiSC issued 09, 2007 A

0

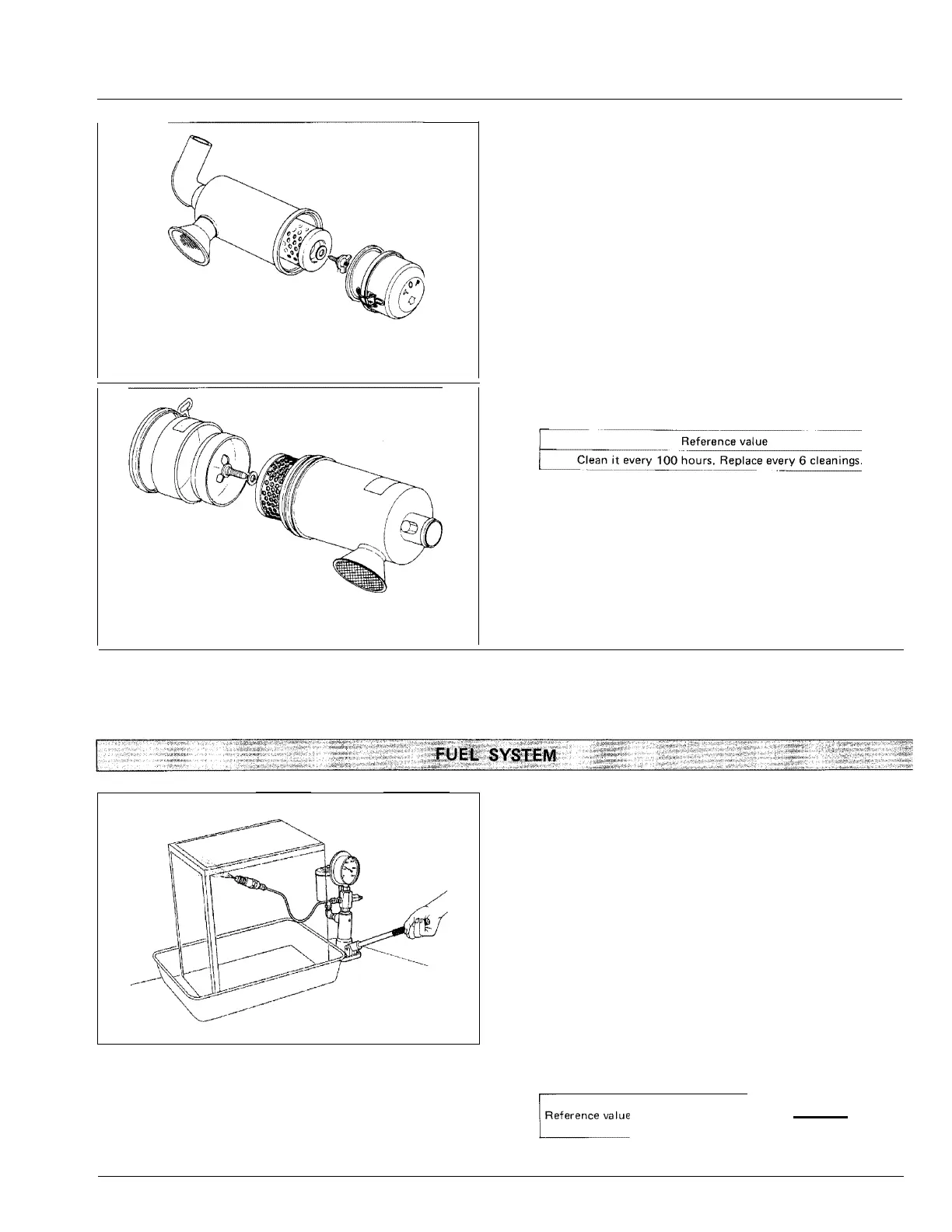

Testing Open

i

ng Pressu re of Nozzle

1)

Move the tester handle up and down to prime fuel.

Measure the pressure of fuel gushing out from the nozzle

tip.

2)

If the measurement is not within the reference value,

adjust with the adjustment washer inside the nozzle

holder. (See page 76) An increase of every 0.1 mm

(

0.0039

i

n.)

of

washer

thickness

causes

an

approximate

980.6

kPa.

(

10 kgf/cm

2

,

142.2 lb./sq.in.) increase in fuel

injection pressure.

( Danger)

•

Be caref ul not to touch the injected fumes directly. On

touchi ng flesh, the f u mes destroy the organism. If it gets

i

n the blood, it may cause blood poisoni ng.

,1

-

o

t

r

:

g

-:-

1

1990.8

to

2133.0

l

b.ls

·-

----

·

·

55

CE,

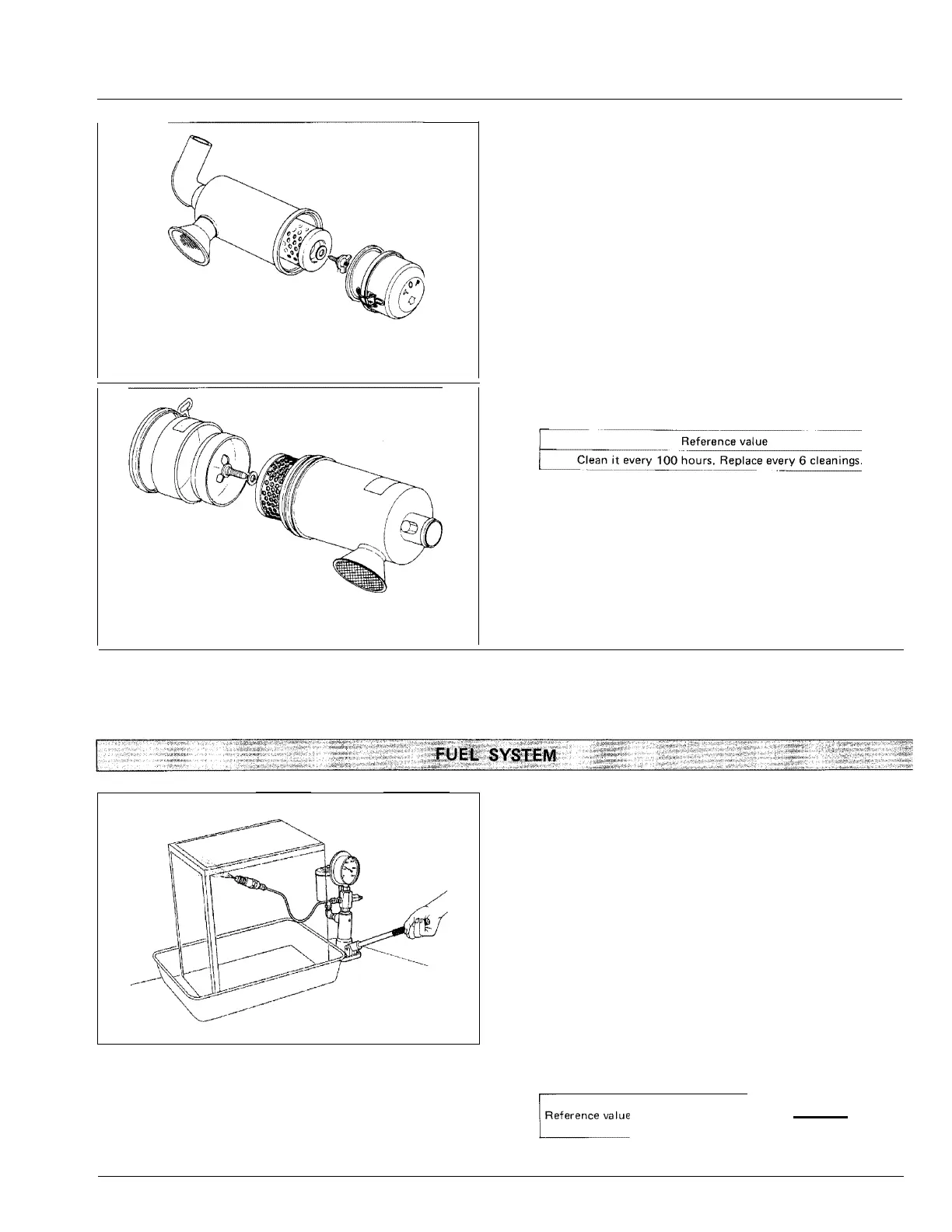

Cleaning Air Cleaner Element

For a dry type element

1)

How to clean by using compressed air:

Directly blow compressed air from inside to outside.

Pressure of compressed air must be under 205kPa

(2.1kgf/cm

2

,30psi).

2)

How to clean by using solution:

Add 15 g

(0.03 lb.) Kubota genuine element detergent to

1 liter

(0.26

gal.) water. Let the element soak in the

solution for 15 minutes and then wash it well in the

solution. R inse well in clean water and dry.

0071

001

01102-B

01302-B

01402-B

•

To remove d

i

rt and dust, use compresse

air.

•

To remove carbon and grease, use solution.

V1502-B

V1702-B

V1902-B

0071F 002

3TLABAB1 P040A

Loading...

Loading...