KiSC issued 09, 2007 A

(

,)

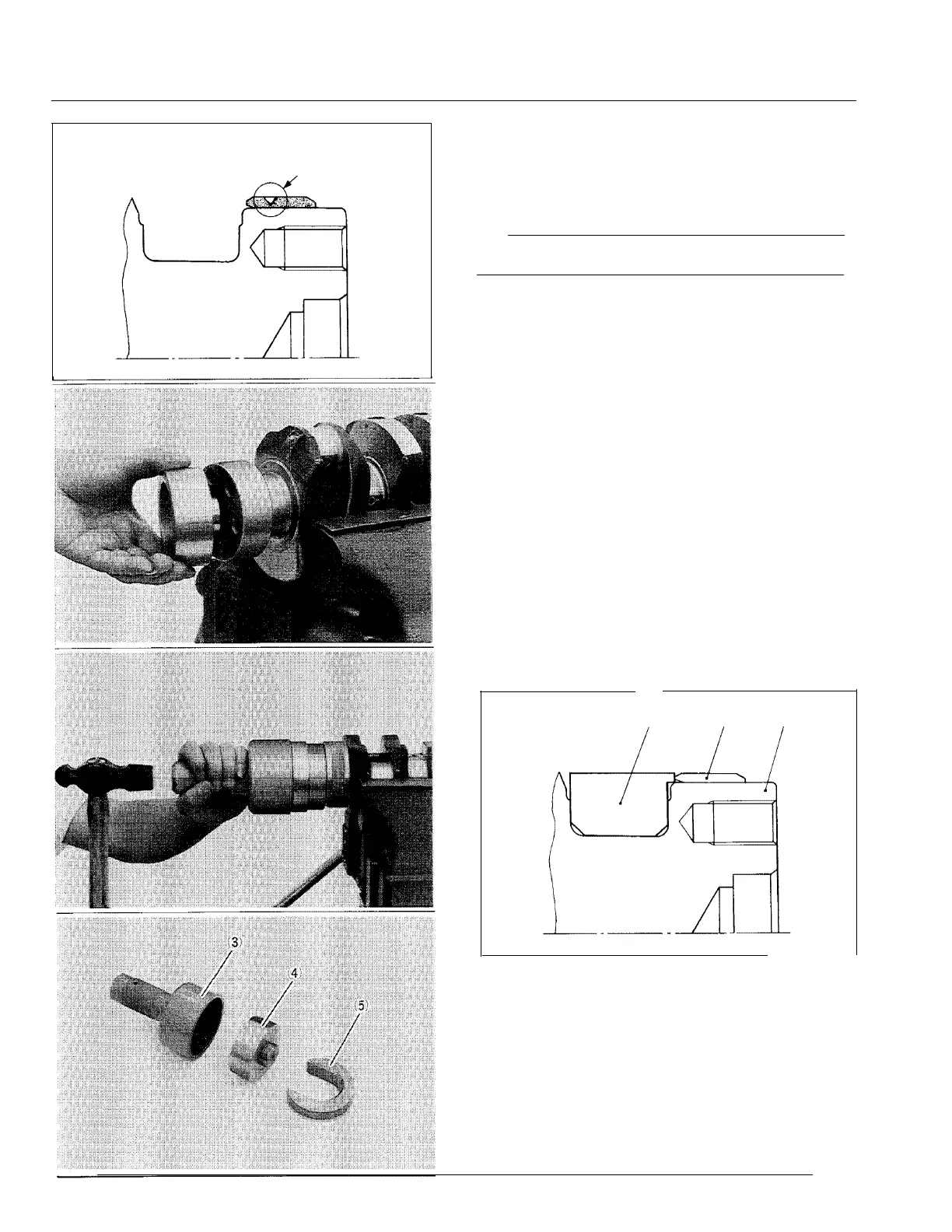

(it Crankshaft Sleeve Wear

1)

) Measu re the wear of the cra n ksh af t sl eeve usi ng a su

rface rough ness tester.

2)

I

f the m easu remen t exceeds the al

l

owabl e

l i

m

i

t, repl ace

the cra n kshaf t sl eeve.

Crankshaft

sleeve wear

( 1)

Wear

Allowable

limit

0.1

mm

0.0039

in

0 107F069

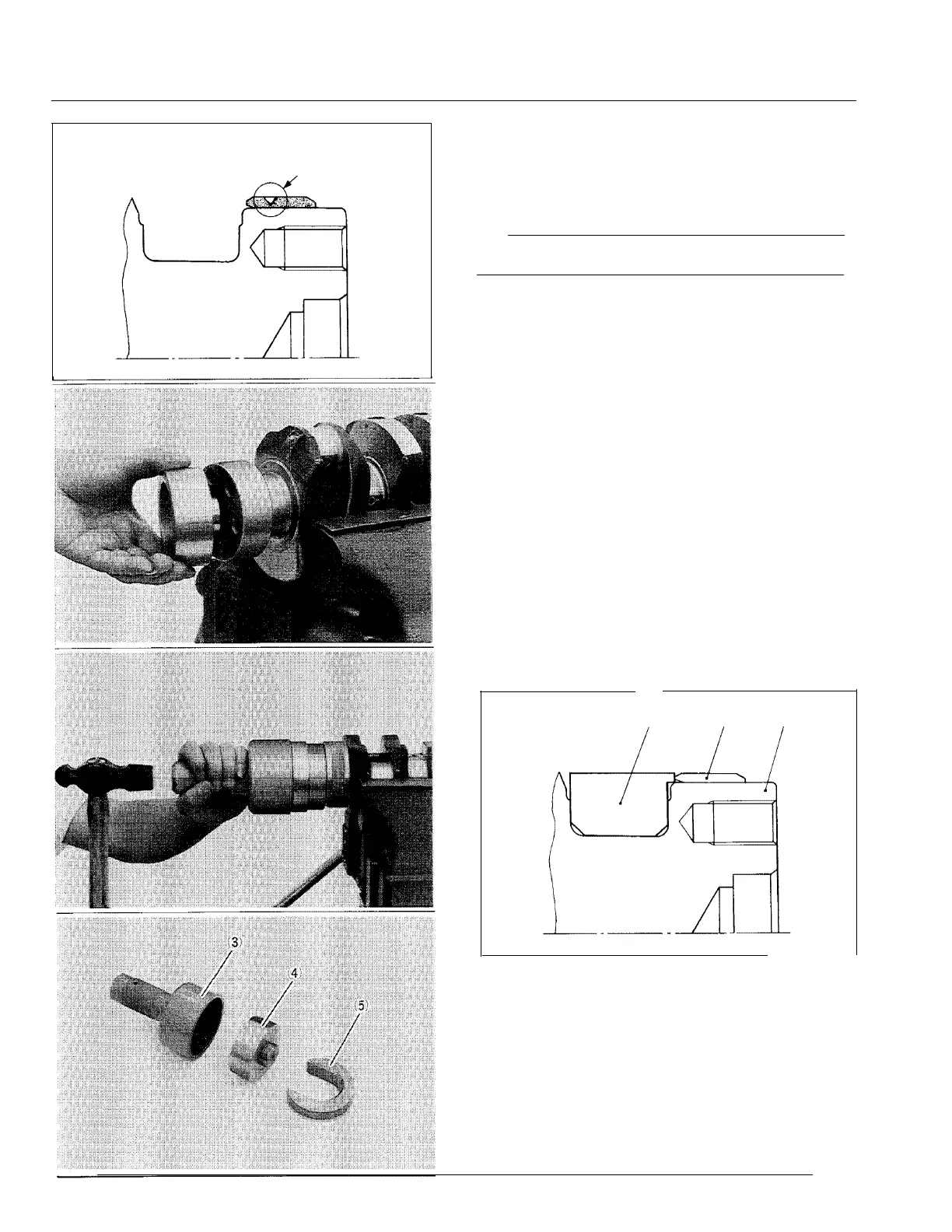

@ Replacing Crankshaft Sleeve

1)

R emove the used cra n kshaf t sl eeve usi ng a speci a

l

-use

pu

l l

er set (Code No. 07916-09032) .

2)

Set the sl eeve gu ide (4) to the cra n kshaf t.

3)

Set the stoppe

r

(5) to th e cra n kshaf t as sh own

i n f

igu re.

4)

Heat a new sl eeve to a tem peratu re between 150 a nd

200°C (302 a nd 392° F ), a nd f

i

x the sl eeve to the cra n k-

sh af t as shown

i

n f

i

gu re.

5)

Press

f i

t the sl eeve usi ng the au x

i

l

i

a

r

y socket for push

i

ng

(3).

•

Tool: Auxiliary socket for fixing the crankshaft

sleeve (Code No. 07916-32091)

(

1)

Crankshaf t Sleeve

( 2) Crankshaft

(3) Auxiliary Socket for Pushing

(4)

Sleeve Guide

(5)

Stopper

68

5

,

2

010

F070

Loading...

Loading...