1-S51

G2160, WSM

ENGINE

[5] FUEL SYSTEM

(1) Checking and Adjusting

(A) Injection Pump

Injection Timing

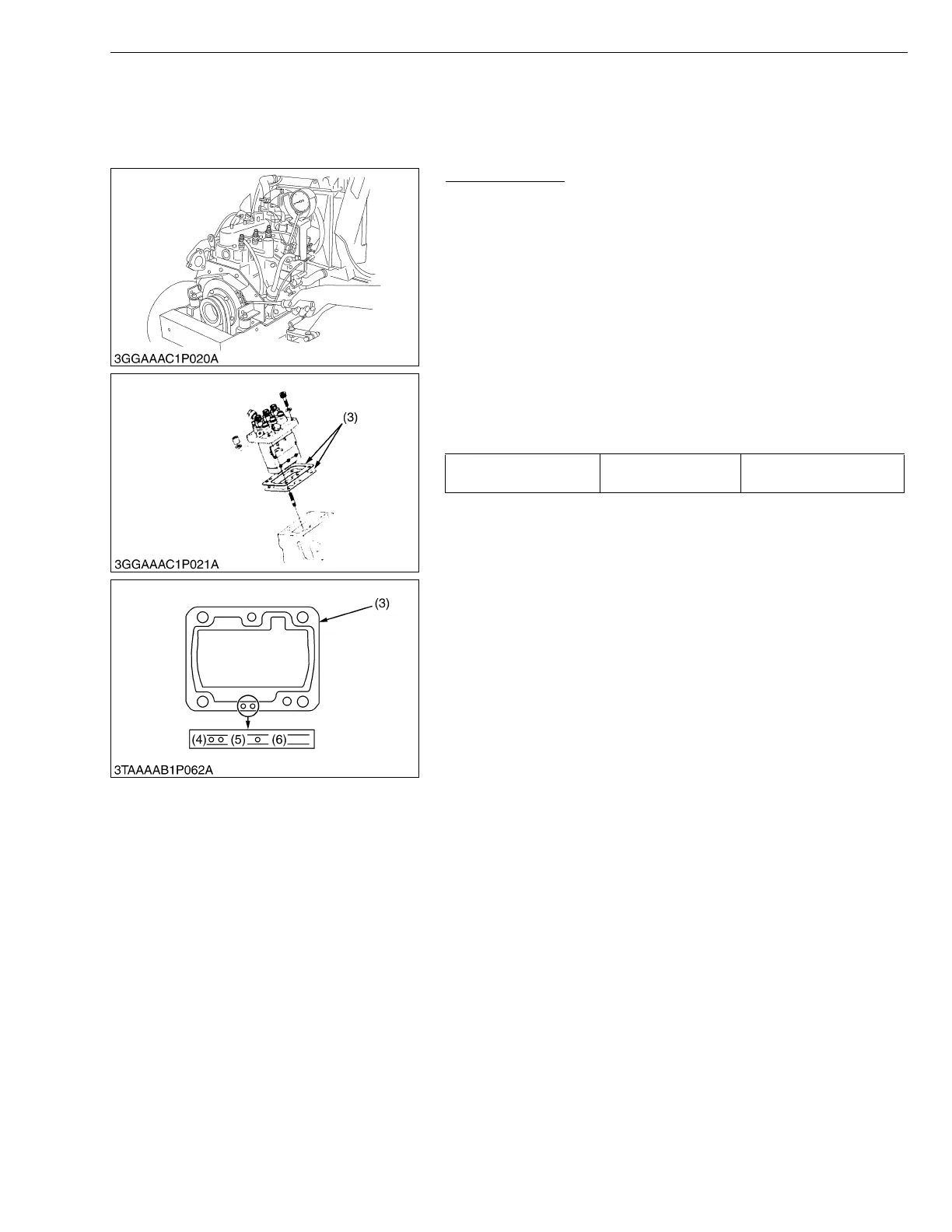

1. Remove the bonnet and air cleaner.

2. Remove the muffler.

3. Remove the injection pipes and glow plugs.

4. Engage the parking brake.

5. Set the throttle lever to the maximum engine speed.

6. Turn on the key switch.

7. Turn the flywheel counterclockwise (facing the flywheel) until fuel

flows from the delivery valve holder (1).

8. Continue to turn the flywheel slowly, and stop it as soon as the

fuel level at the tip of the delivery valve holder begins to increase.

9. Check to see if the timing angle lines on the flywheel is aligned

with the alignment mark (2).

10.If the injection timing is out of adjustment, readjust the timing with

shims (3).

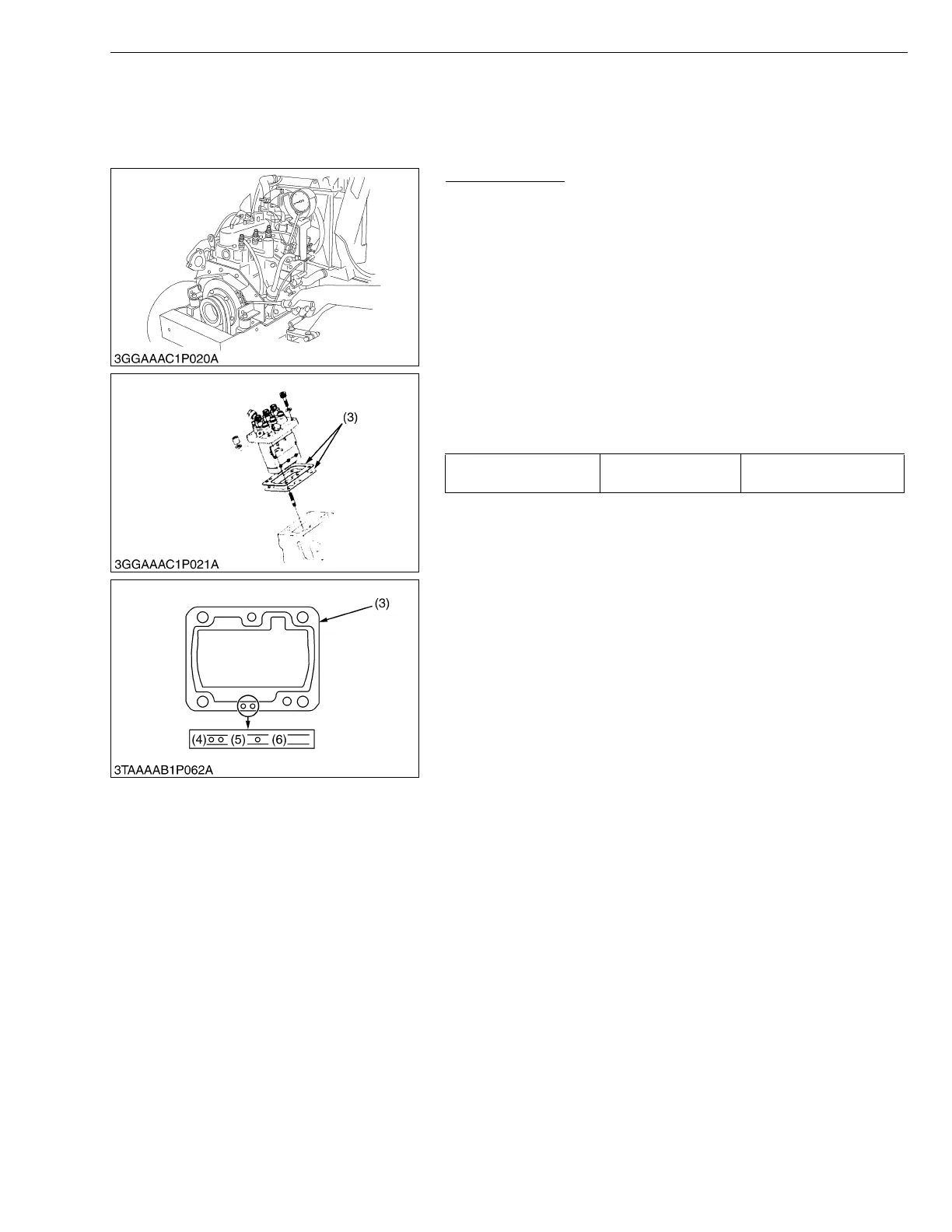

• The sealant is applied to both sides of the shim (soft metal

gasket shim). The liquid gasket is not required for

assembling.

• Shims are available in thickness of 0.20 mm (0.0079 in.), 0.25

mm (0.0098 in.) and 0.30 mm (0.0118 in.). Combine these

shims for adjustments.

• Addition or reduction of shim (0.05 mm, 0.0020 in.) delays or

advances the injection timing by approx. 0.0087 rad (0.5 °).

• In disassembling and replacing the injection pump, be sure

to use the same number of new shims with the same

thickness.

• Refer to figure left to check the thickness of the shims.

W10397720

Injection timing Factory spec.

0.33 to 0.37 rad

(19 to 21 °) before T.D.C.

(1) Delivery Valve Holder

(2) Alignment Mark

(3) Shim

(4) Shim with Two-holes : 0.20 mm

(0.0079 in.)

(5) Shim with One-hole : 0.25 mm

(0.0098 in.)

(6) Shim with No hole : 0.30 mm

(0.0118 in.)

Loading...

Loading...