4. FUEL SYSTEM

4-7

VENOX250/250i

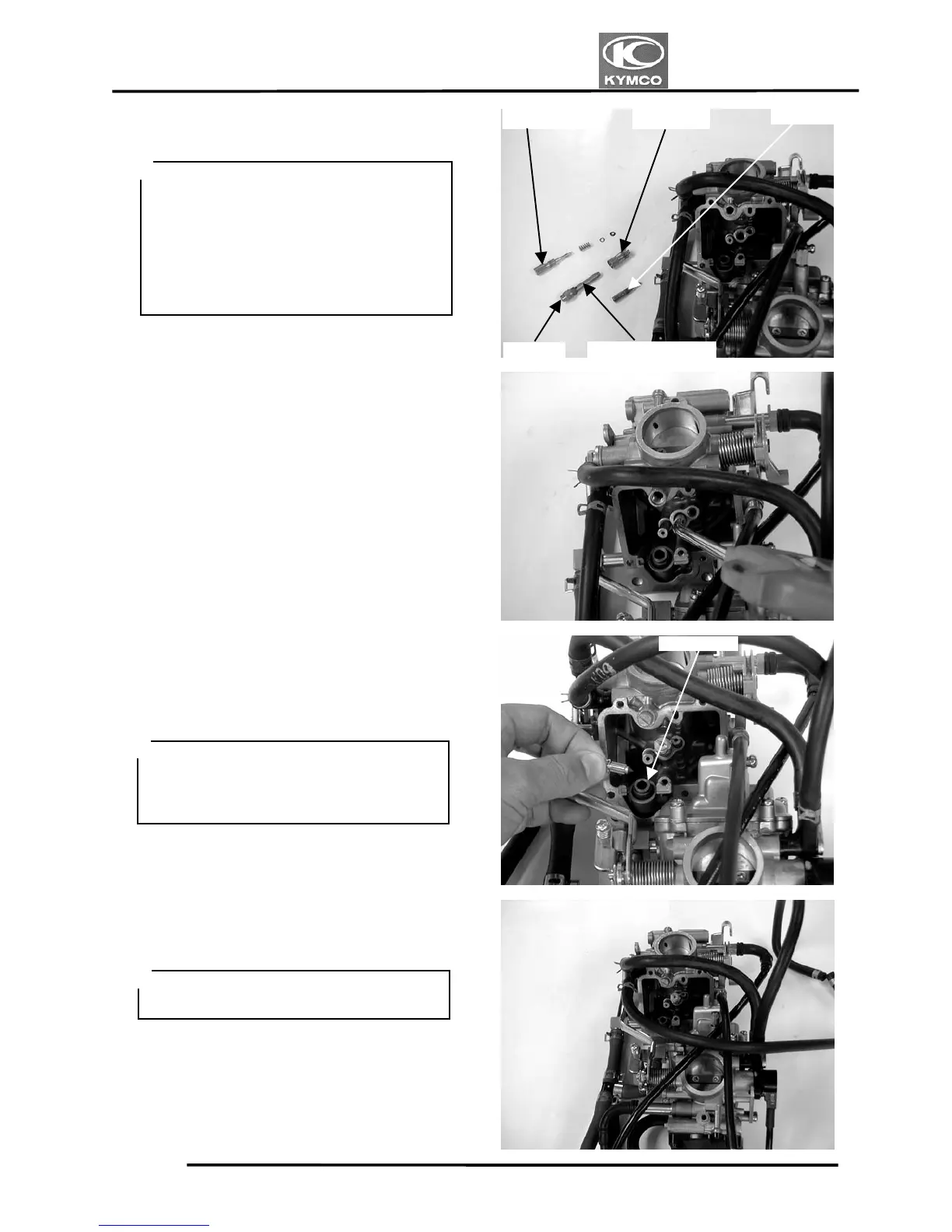

Remove the main jet, needle jet holder,

needle jet, slow jet and pilot screw.

Clean the removed fuel jets with detergent

oil and blow them open with compressed air.

Blow compressed air through all passages of

the carburetor body.

INSPECTION

Inspect the float valve and valve seat for

damage or clogging.

Inspect the float valve and valve seat contact

area for stepped wear or contamination.

ASSEMBLY

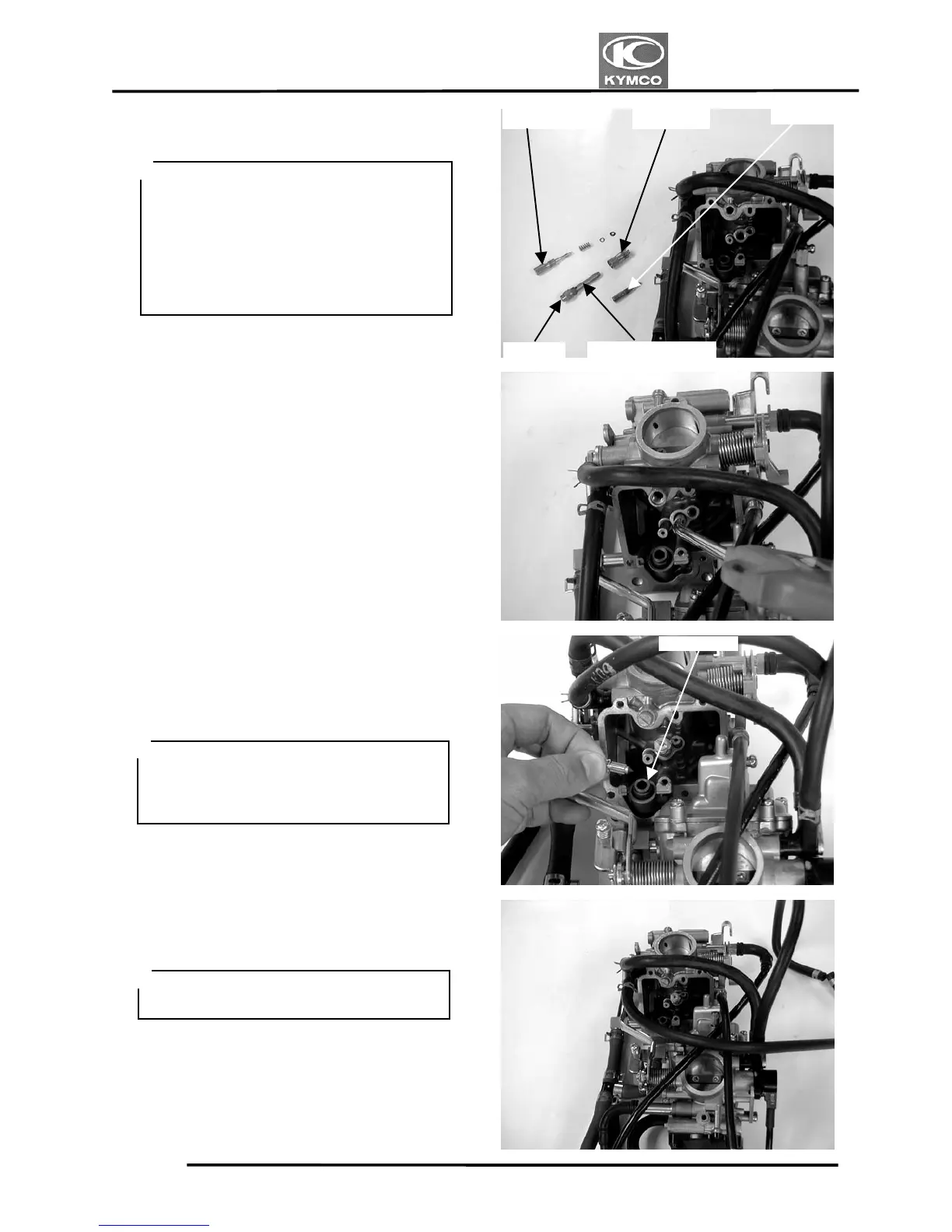

Install the slow jet, needle jet, needle jet

holder, main jet and pilot screw.

Standard Opening: 2r½ turns

xBe careful not to damage the fuel jets

and pilot screw.

xBefore removing, turn the pilot screw

in and carefully count the number of

turns until it seats lightly and then

make a note of this.

xDo not force the pilot screw against its

seat to avoid seat damage.

*

Worn or contaminated float valve an

valve seat must be replaced because it

will result in float level too high due to

incomplete airtightness.

*

Return the pilot screw to the original

position as noted during removal.

*

Loading...

Loading...