4. FUEL SYSTEM

4-8

VENOX250/250i

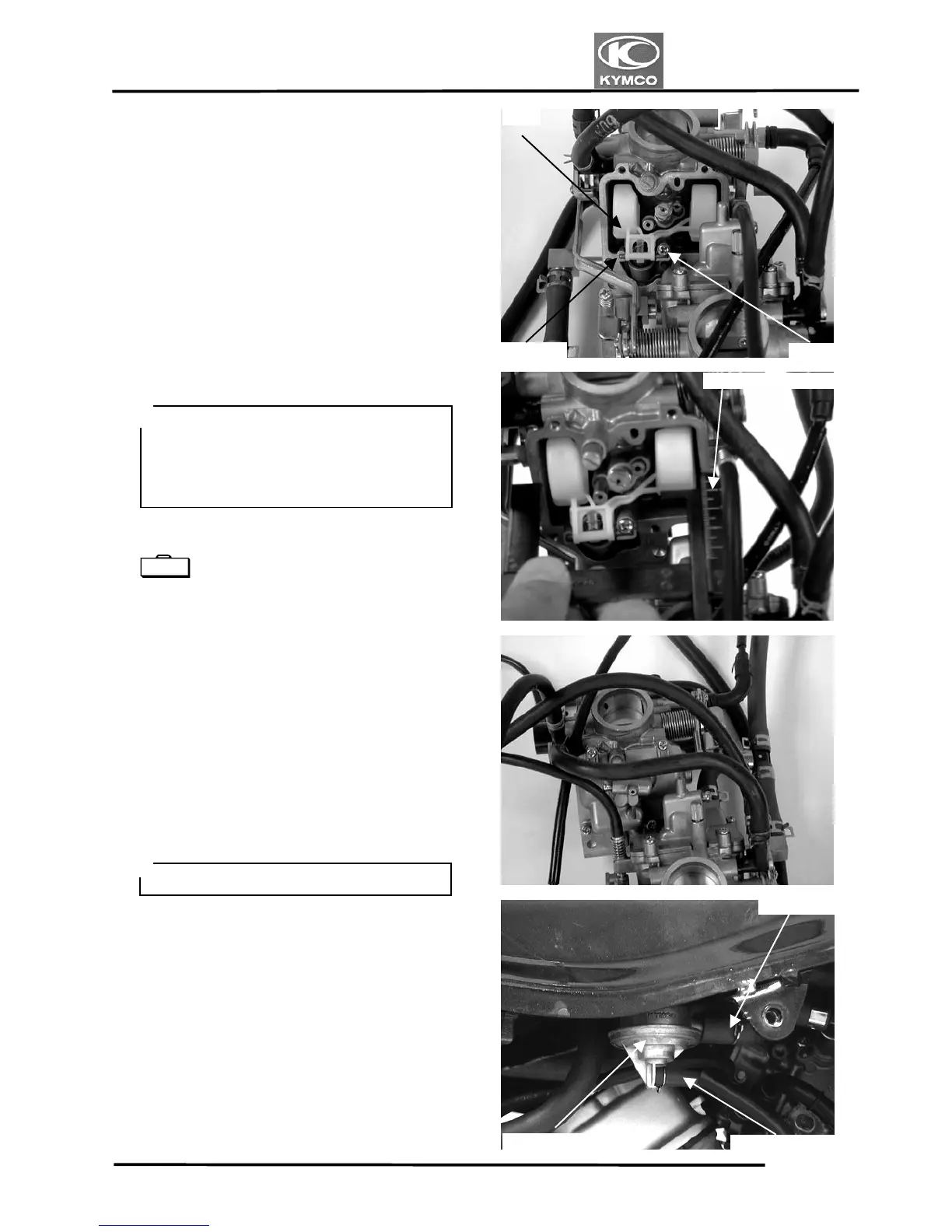

Install the float valve, float and float pin.

Secure the float pin with the screw.

FLOAT LEVEL INSPECTION

Measure the float level.

Float Level:Front:17.5mm , Rear:19.0mm

Float Level Gauge

INSTALLATION

The installation sequence is the reverse of

removal.

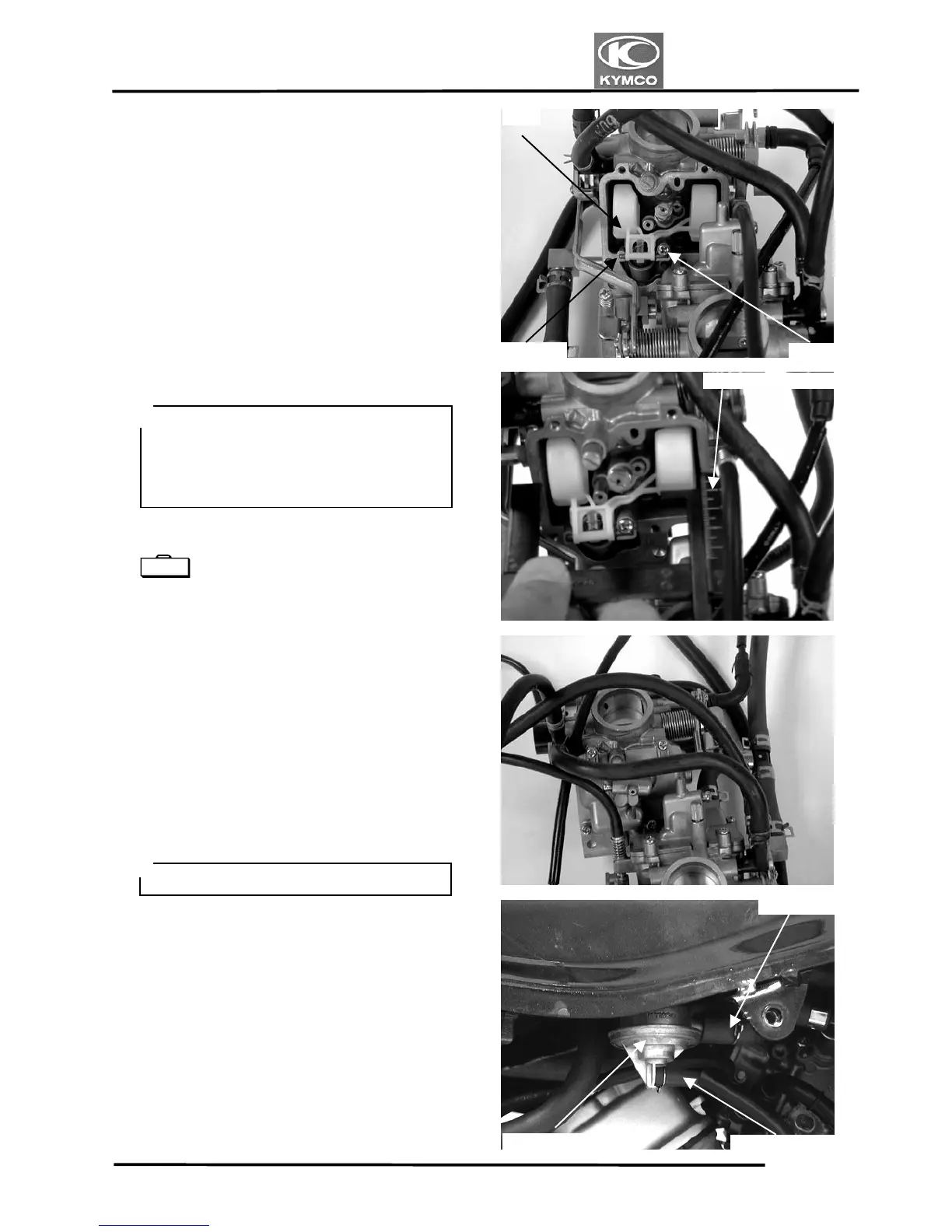

AUTO FUEL VALVE

Disconnect the fuel tube and vacuum tube

from the carburetor.

Connect a vacuum pump to the vacuum tube

and apply vacuum. Check if fuel flows out.

The valve is operating normally if fuel flows

out of the fuel tube when the vacuum is

applied.

The fuel shall stop flowing out when the

vacuum pump is disconnected.

If the fuel valve does not operate normally,

Check the vacuum diaphragm for poor

installation or damage and inspect the fuel

tube for clogging.

xCheck the operation of the float valve

and float before this inspection.

xMeasure the float level by placing the

float level gauge on the float chamber

face parallel with the main jet.

*

S

Loading...

Loading...