90-830234R3 DECEMBER 1997 MID-SECTION - 5B-29

Cleaning and Inspection of

Trim Rod Components

CAUTION

Do not remove check ball components from trim

rod piston. Removal and re-installation of check

valve could result in improper operating pres-

sure and possible power trim system damage.

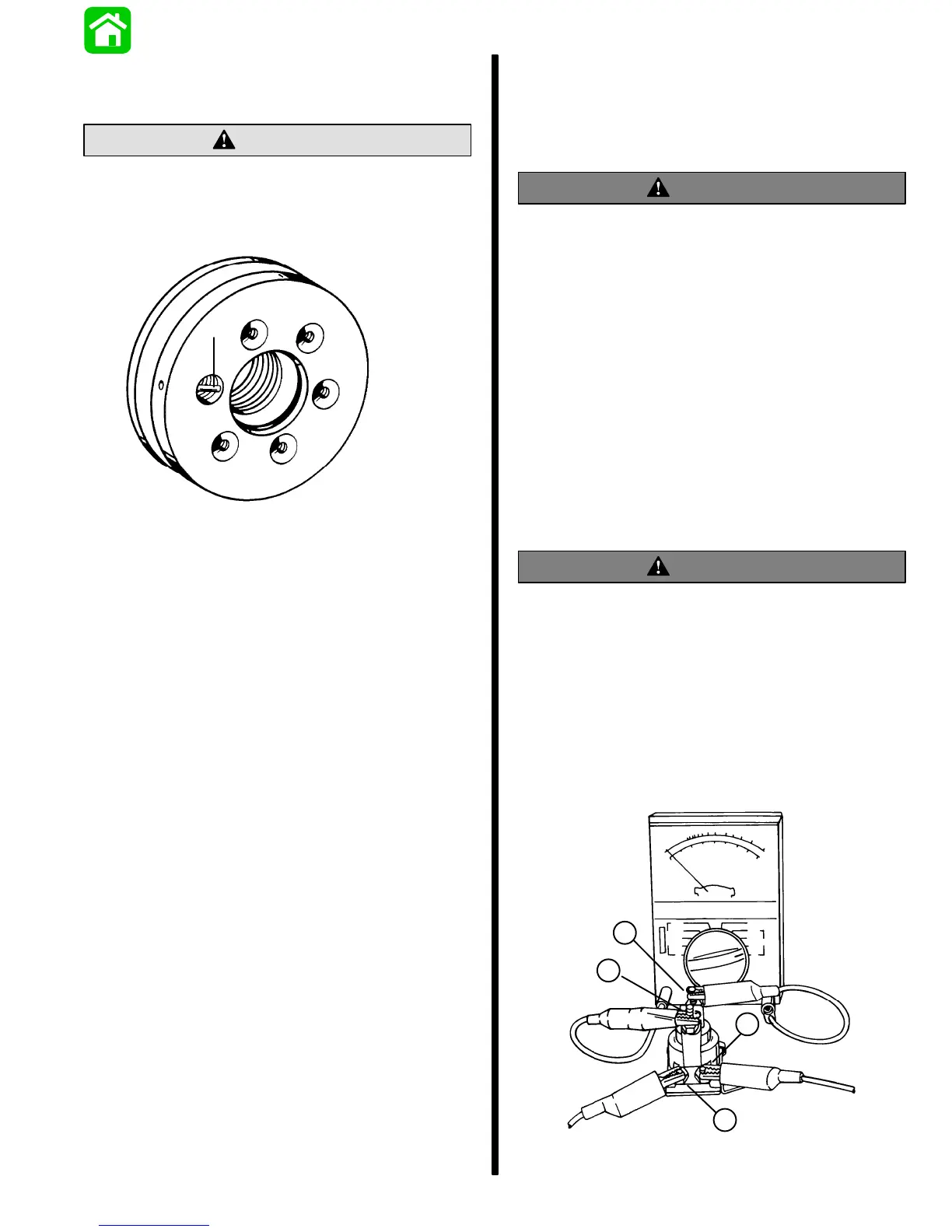

a

51199

a - Check Ball Components

Inspect check valve for debris; clean debris form

check valve if found. If debris cannot be cleaned from

check valve, replace trim rod piston as an assembly.

Clean trim rod and components with parts cleaner

and dry with compressed air.

It is recommended that all O-rings in trim system be

replaced.

Inspect trim rod. If scraper (located in cap) has failed

to keep rod clean, replace scraper.

Lubricate all O-rings using Quicksilver Power Trim

and Steering Fluid or; (ATF) Type F, FA or Dexron III.

Motor and Electrical

Tests/Repair

Trim Pump Motor Test

WARNING

Do not perform this test near flammables (or ex-

plosives), as a spark may occur when making

connections.

1. Disconnect GREEN (motor) wire and BLUE (mo-

tor) wire from trim system wiring harness.

2. Connect a 12 volt power supply to motor wires

(POSITIVE to BLUE; NEGATIVE to GREEN re-

sults in motor up direction. POSITIVE to GREEN;

NEGATIVE to BLUE results in motor down direc-

tion). Motor should run.

3. If motor does not run, disassemble motor and

check components.

Solenoid Test

WARNING

Do not perform this test near flammables (or ex-

plosives), as a spark may occur when making

connections.

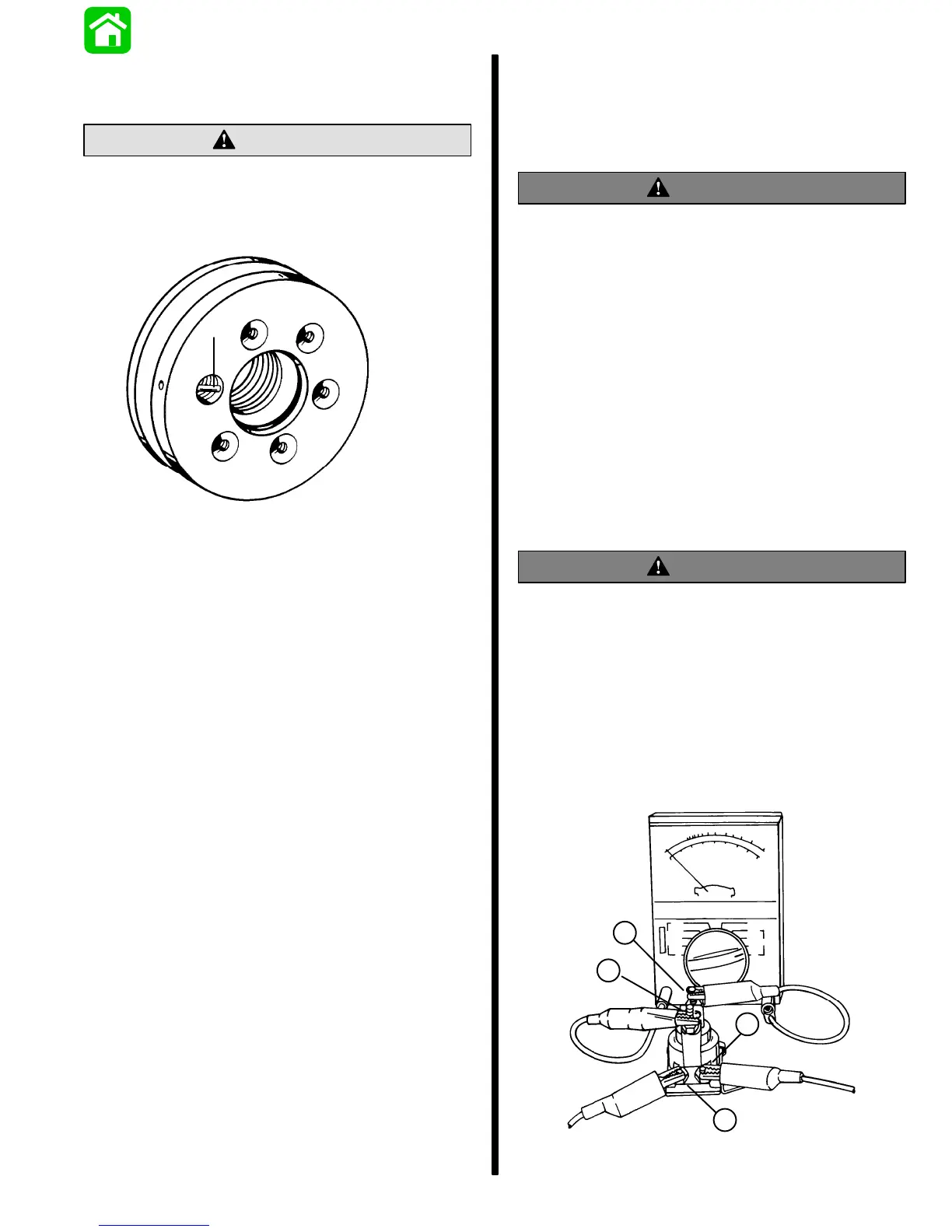

1. Disconnect all wires from solenoid terminals.

2. Set ohmmeter to Rx1 scale and connect meter to

solenoid terminals 1 and 2.

3. Connect a 12 volt power supply to terminals 3 and

4. Solenoid should click and meter should read

zero (0) ohms (full continuity).

1

2

4

3

51338

Loading...

Loading...